A self-adjusting pretension steel wire rope sling

A self-adjusting technology for steel wire ropes, applied in hoisting devices, clockwork mechanisms, etc., can solve problems affecting the life of components that affect the stability of operations, affect the effective operating height, and cannot be adjusted in time, so as to save cumbersome labor , Excellent appearance quality, strong adhesion and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in further detail now in conjunction with accompanying drawing.

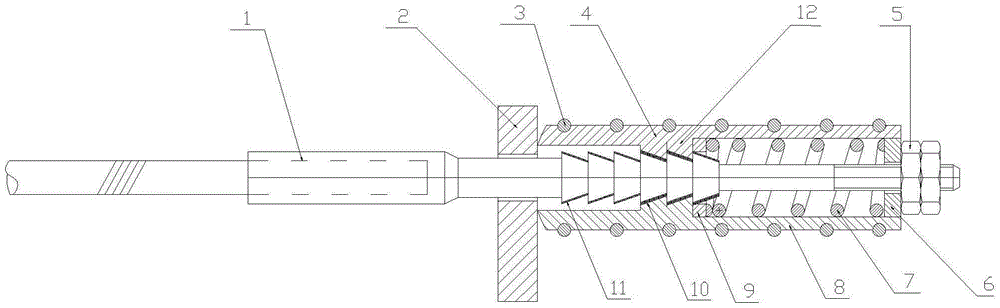

[0013] Such as figure 1 As shown, a self-adjusting pre-tightening steel wire rope sling includes a sling body 1, a plurality of outer conical trapezoidal protrusions 11 are arranged in the middle of the sling body 1, and buckles are arranged on the outside of the outer conical trapezoidal protrusions 11. The combined upper semicircle 4 and lower semicircle 8, one end of the upper semicircle 4 and the lower semicircle 8 is provided with a fixed plate 2, and the other end is provided with an outer spring seat 6, and the rigging body 1 passes through the fixed plate 2 and the outer spring seat 6 are fixed with a lock nut 5, and the inner middle part of the upper semicircle body 4 and the lower semicircle body 8 is provided with a protrusion 12, and a cavity is formed between the protrusion 12 and the outer spring seat 6, A helical spring 7 is sheathed on the rigging body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com