A bar forming machine

A molding machine and bar material technology, applied in the direction of wood compression, etc., can solve the problems of increasing the cost of use, limitation, and reducing the service life of the screw and power transmission mechanism, so as to prolong the service life, reduce the cost of use, improve the use efficiency and use effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

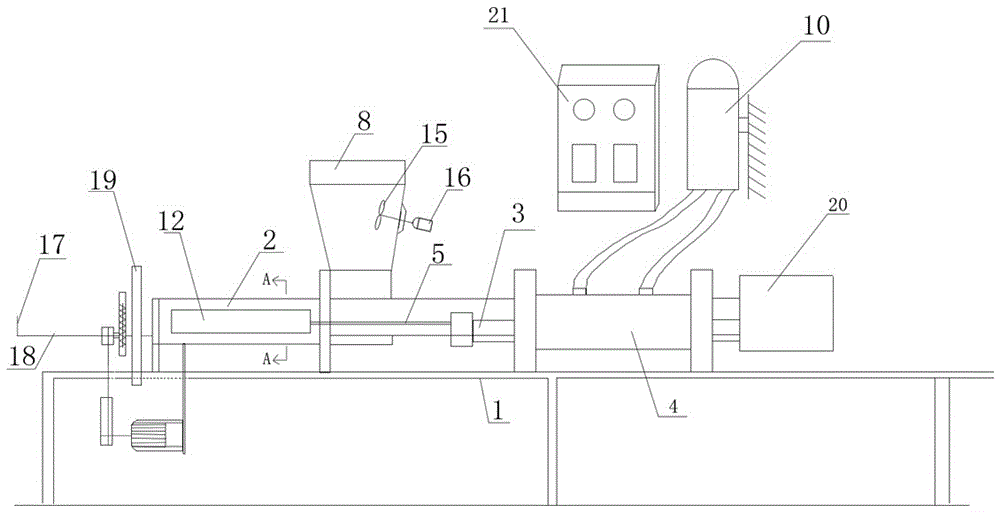

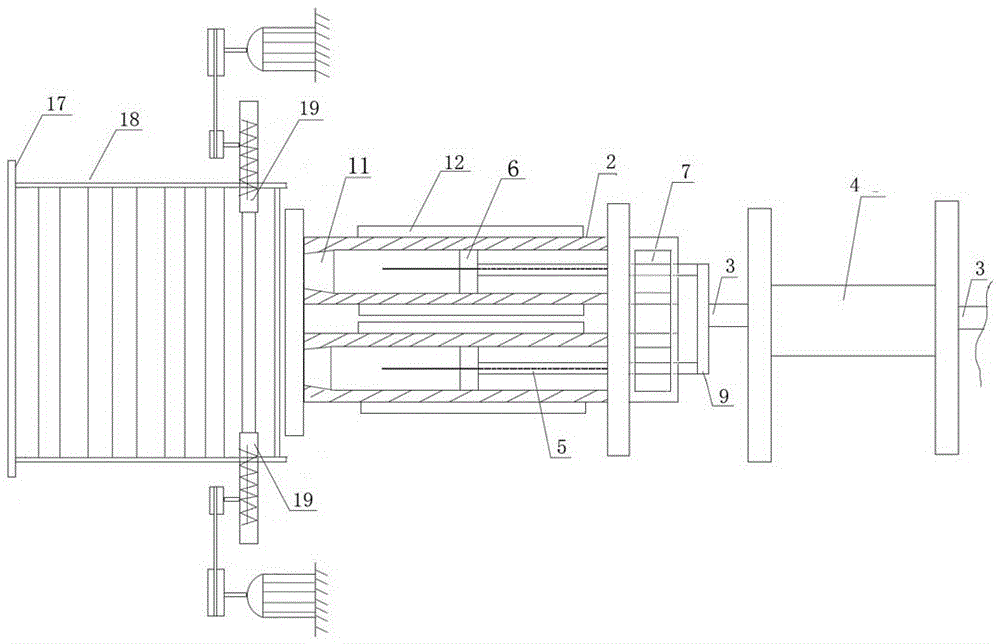

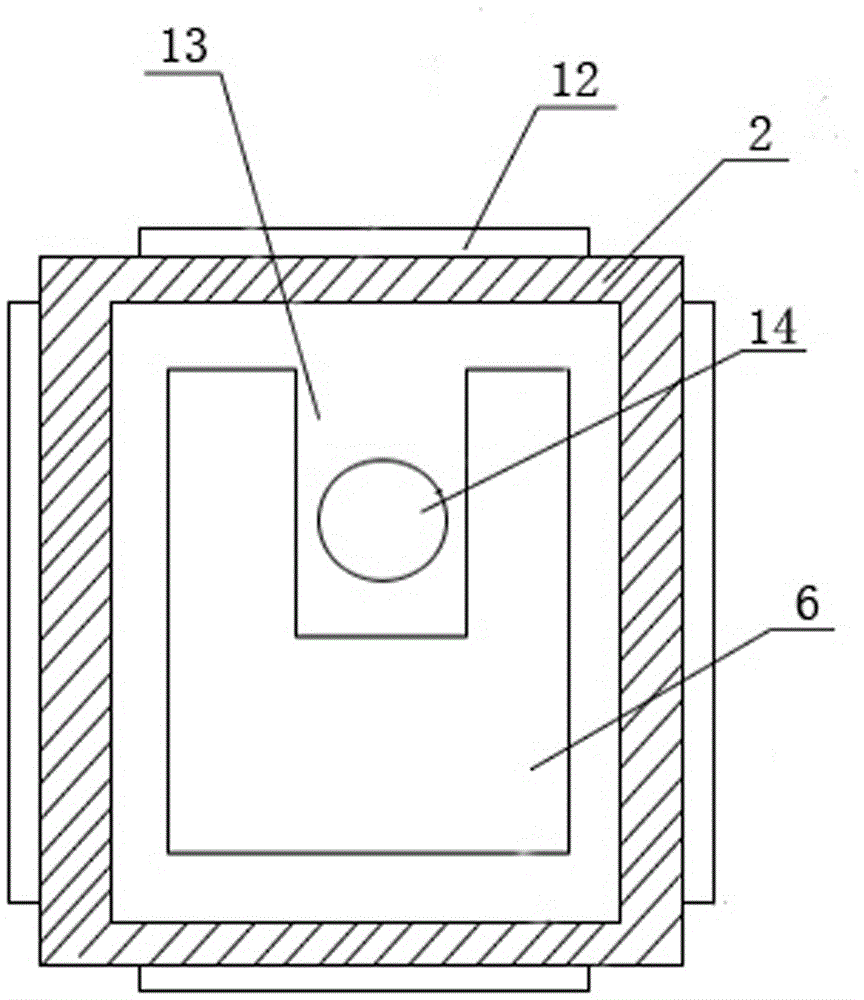

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings: figure 1 , 2 As shown in the figure, the bar forming machine according to the present invention at least includes a frame 1, on which at least a horizontal extrusion forming cylinder 2 is installed, and the feeding port of the cylinder 2 is a A hydraulic cylinder 4 with a piston rod 3 is installed on the side; the piston rod 3 is connected with an extrusion block 6 which is placed in the cylinder with the same cross-sectional shape of the extrusion cavity through the connected extrusion rod 5; The inside of the feeding port of 2 is provided with a blanking port 7 which communicates with the extrusion cavity in the cylinder. The blanking port 7 is equipped with a hopper 8 and constitutes a bar extrusion molding device.

[0016] The frame 1 shown in the figure is installed with two extruded cylinders 2 arranged side by side, the piston rod 3 of the hydraulic cylinder 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com