Simulation humanoid robot motion stabilizer

A robot motion prevention and human simulation technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of large gaps in the running machinery, wear and tear of motors and deceleration mechanisms, installation errors, etc., and achieve the effect of smooth movement and increased resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

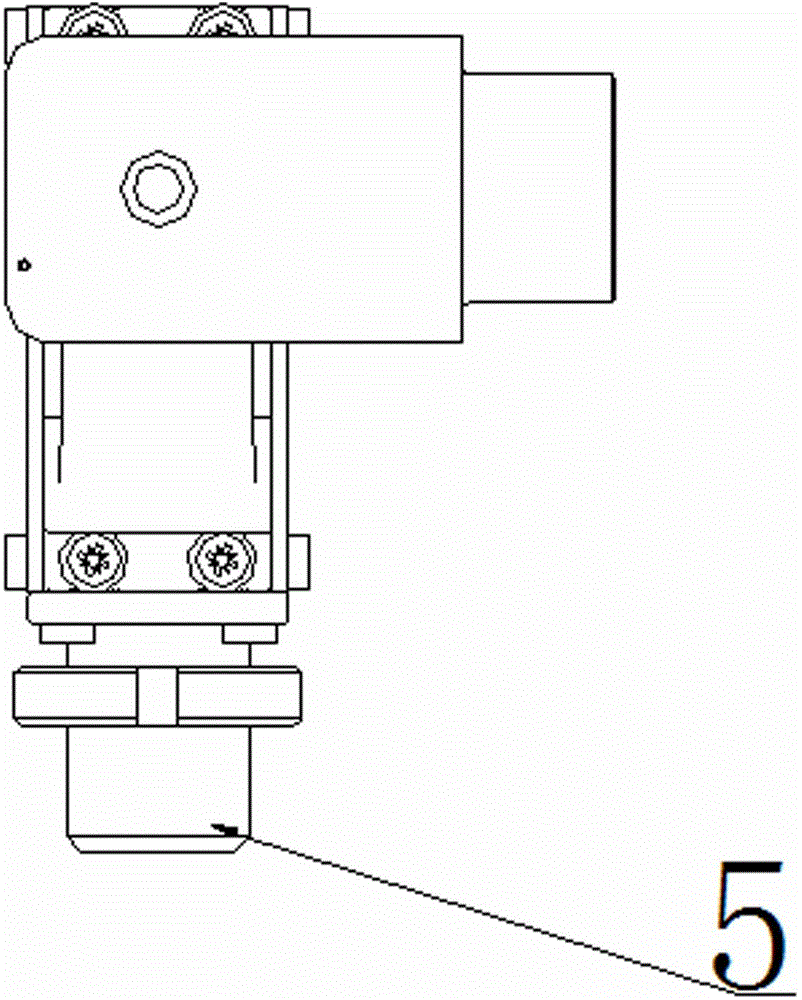

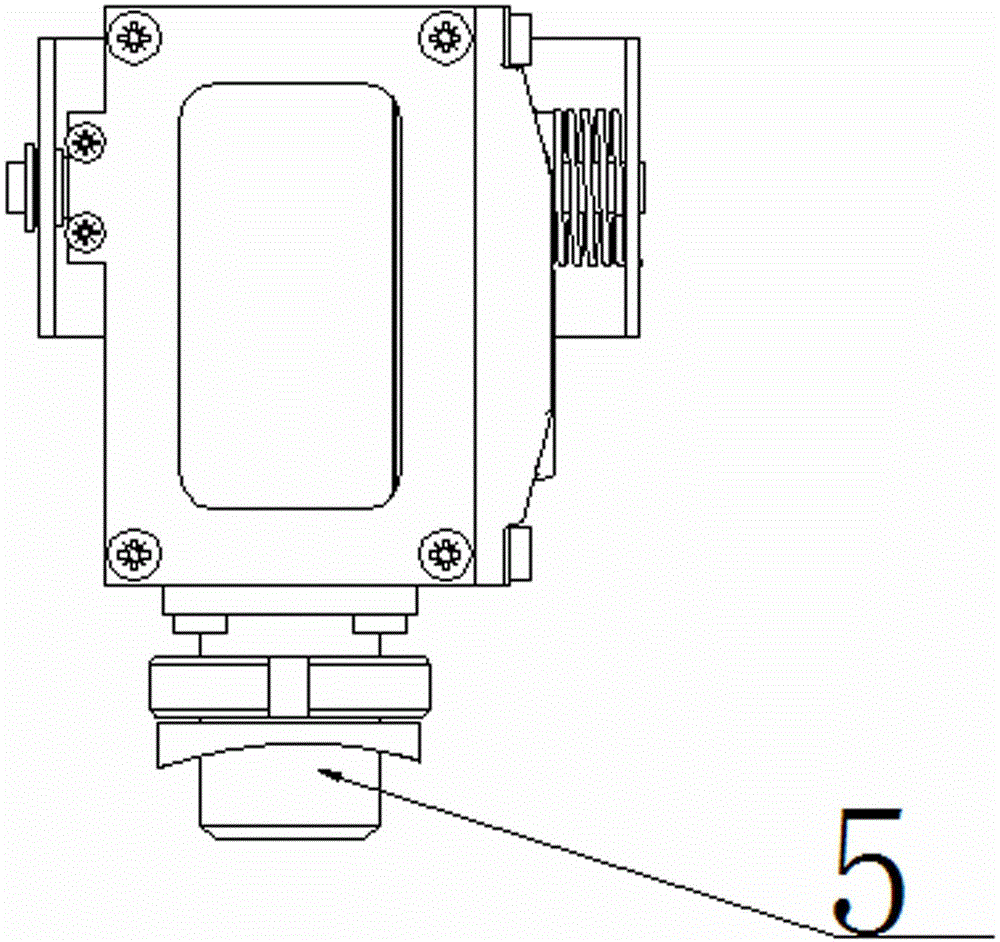

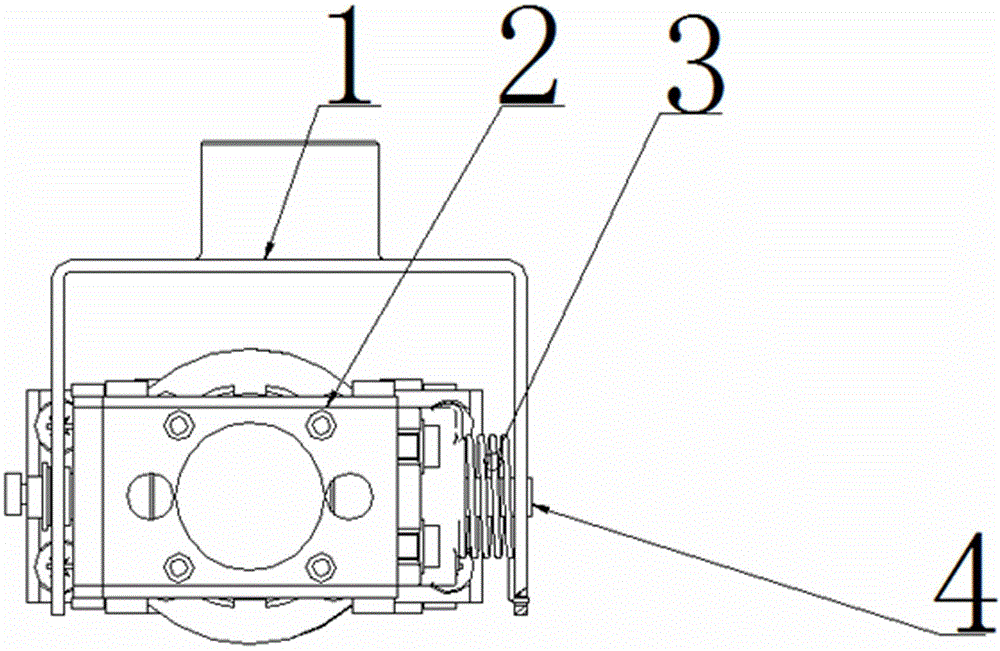

[0014] refer to Figure 1-3 , the specific embodiment adopts the following technical solutions: the motion anti-shake device of the simulated human robot includes a motor bracket 1, a servo motor 2, a torsion spring 3, a rotating shaft 4 and a rotating part 5, the motor bracket 1 is provided with a servo motor 2, and the servo A torsion spring 3 is arranged on the rotating shaft of the motor 2, and the servo motor 2 is connected with the rotating parts.

[0015] In this specific embodiment, a torsion spring is added as a damper in the rotary motion part of the servo motor to increase the resistance when shaking, and overcome the back and forth shaking of the arm. Select the torsion spring according to the output torque of the servo motor.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com