Automobile press fit die transmission and positioning mechanism

A technology of positioning mechanism and automobile, which is applied in the direction of positioning device, metal processing equipment, feeding device, etc. It can solve the problem of increasing the development cost of tooling, the inability to realize the mixed line production of one machine and multiple models of pressing molds, and increasing the closing height of molds, etc. Problems, achieve the effect of reducing the cost of castings, facilitating processing, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

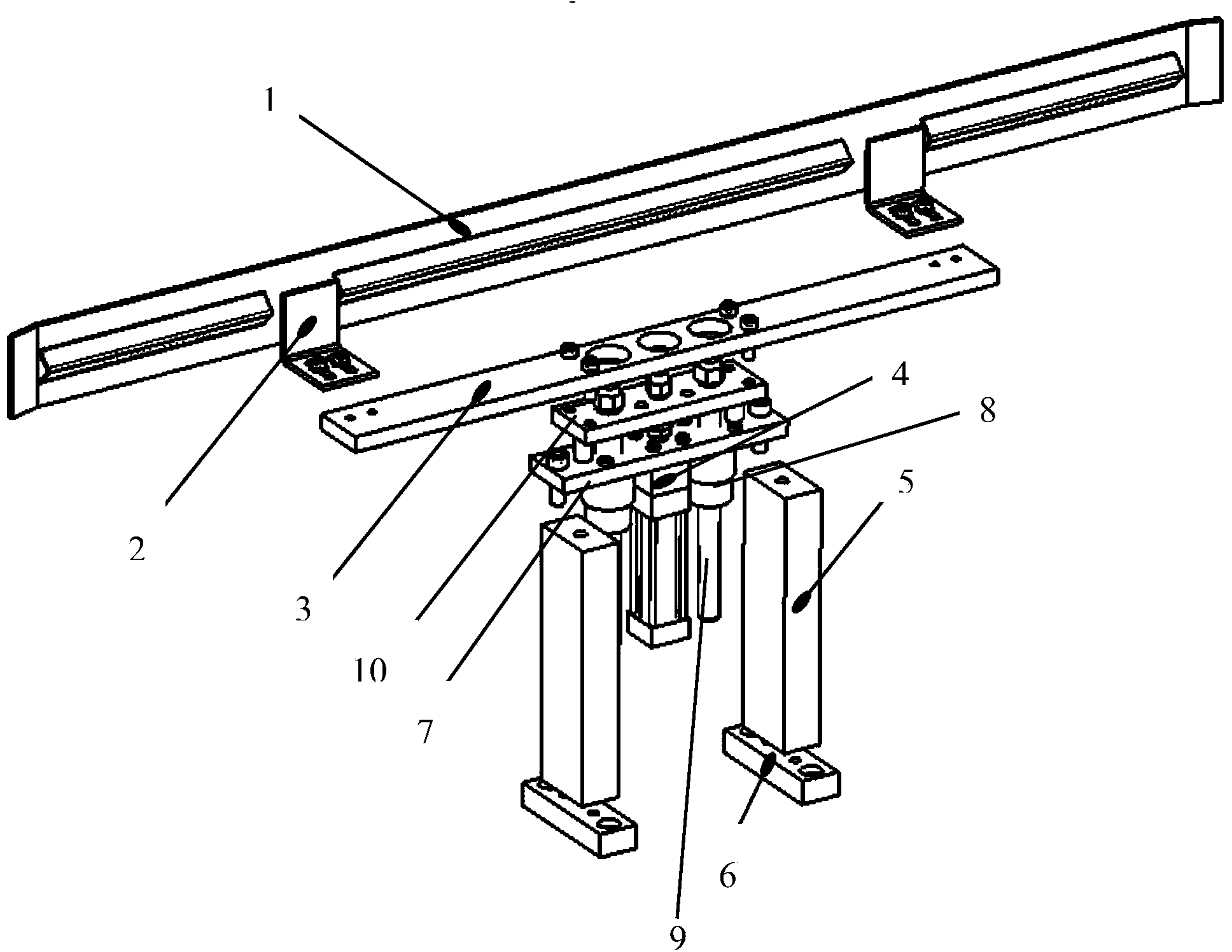

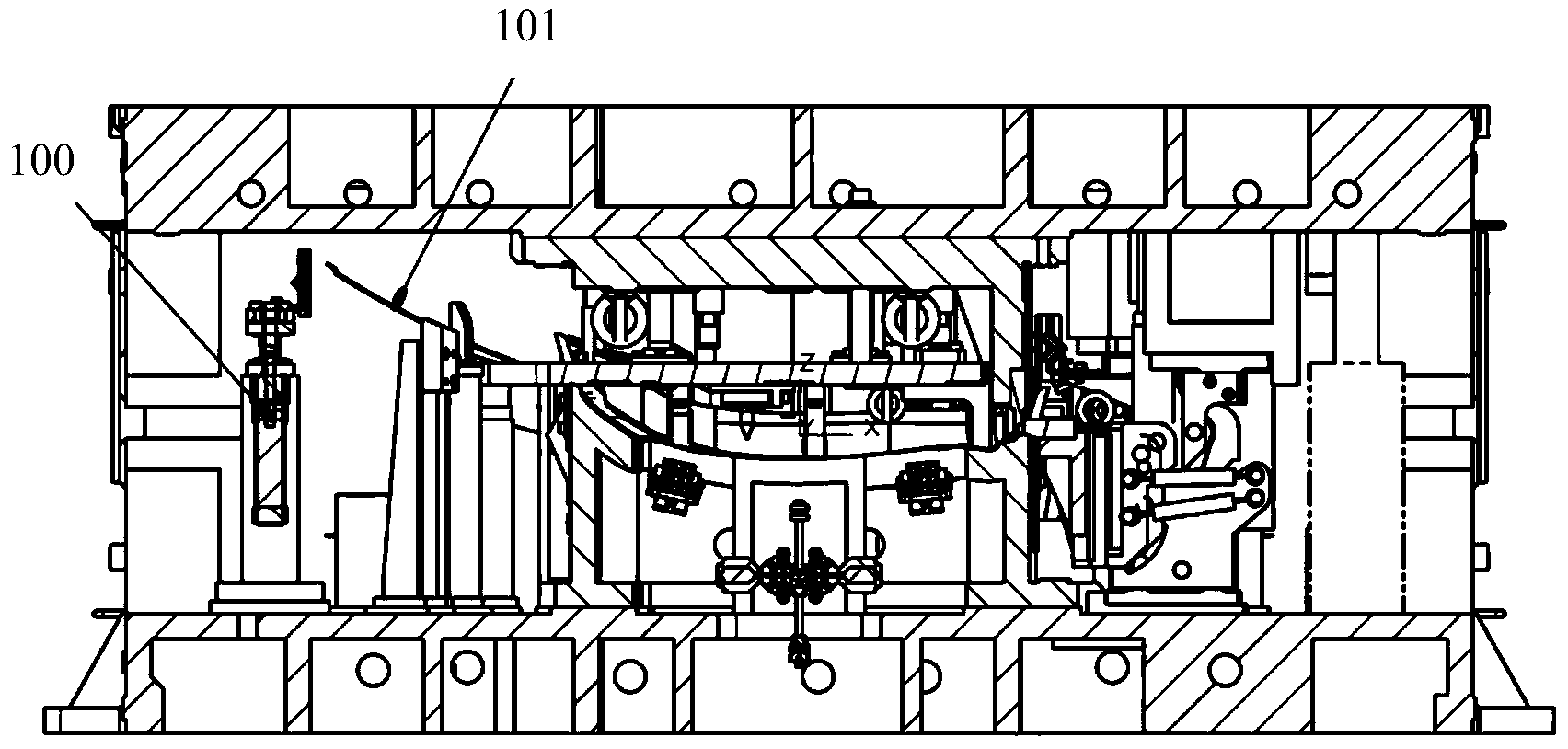

[0030] A kind of automobile compression mold transmission positioning mechanism 100, such as figure 1 with figure 2 As shown, its structure is as follows:

[0031] The assembly transport positioning plate 1 is a steel structure. Preferably, the side of the assembly transport positioning plate 1 facing away from the stamping parts in the automobile press-fitting die is fixed with angle steel, and the angle steel can effectively enhance the structural strength of the assembly transport positioning plate 1 .

[0032] Positioning plate mounting plate 3, its top surface is perpendicular to the stamping direction of automobile press-fitting die.

[0033] The two ends of the top surface of the positioning plate mounting plate 3 are respectively connected by bolts to an L-shaped connecting plate 2, the web of the L-shaped connecting plate 2 is welded to the assembly transport positioning plate 1, and the assembly transport positioning plate 1 faces into the automobile pressing mold...

Embodiment 2

[0042] Compared with Embodiment 1, this embodiment is only a cylinder with a displacement sensor for use in the lifter, and the cylinder body of the cylinder with a displacement sensor is fixed on the bottom surface of the cylinder positioning plate 7, and the free end of the piston rod of the cylinder with a displacement sensor passes through The cylinder positioning plate 7 is fixedly connected with the bottom surface of the positioning plate mounting plate 3. The two ends of the cylinder positioning plate 7 are fixedly equipped with mounting brackets 5 respectively, and the bottom surface of the mounting bracket 5 is fixedly equipped with mounting seats 6, thereby constituting a fixing device. Other structures are also used in the same way as in the first implementation.

[0043] In addition to Embodiments 1 and 2, for stamping parts with complex assembly contours and relatively compact mold space, in order to realize the up and down movement of the automobile press-fit mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com