Wire harness fixing support

A wire harness fixing and wire harness technology, which is applied in the field of brackets, can solve the problems of wire harness shaking and abnormal noise, inconvenient assembly, and no fixing of wire harnesses, etc., and achieves the effect of simple and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

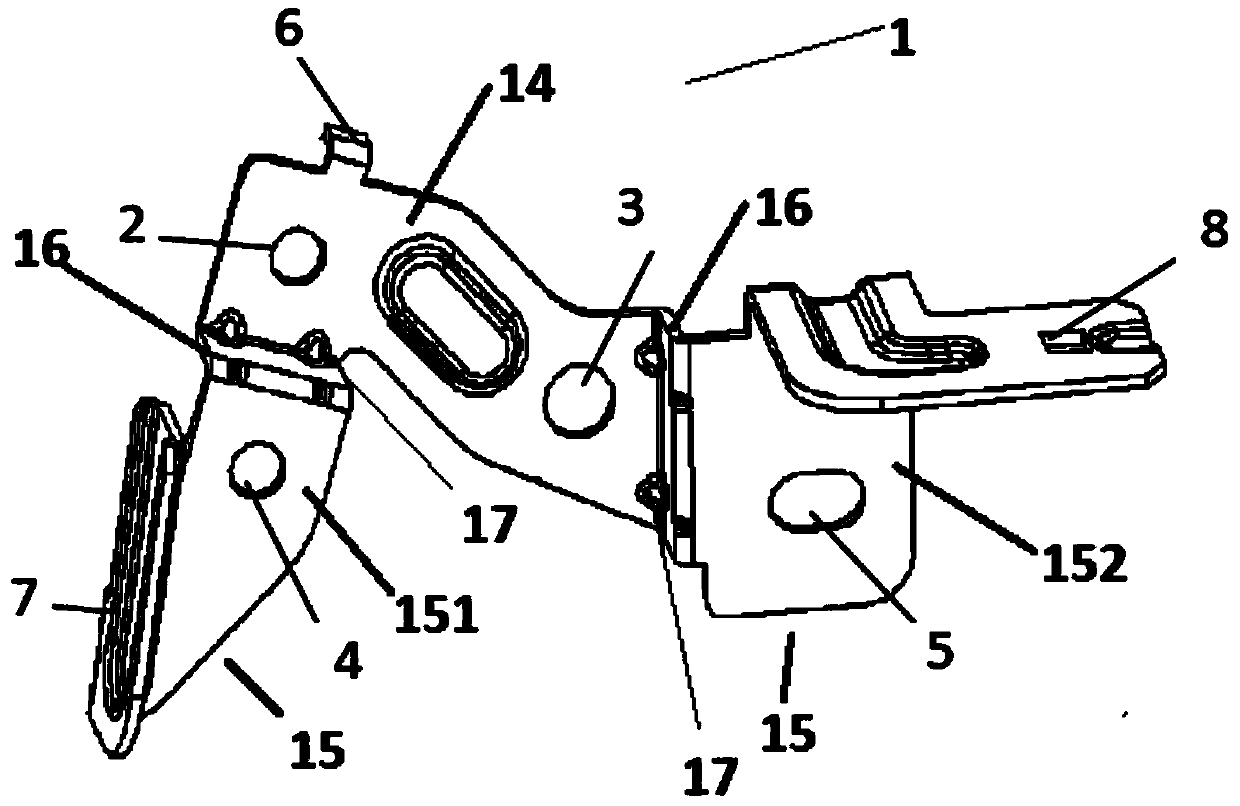

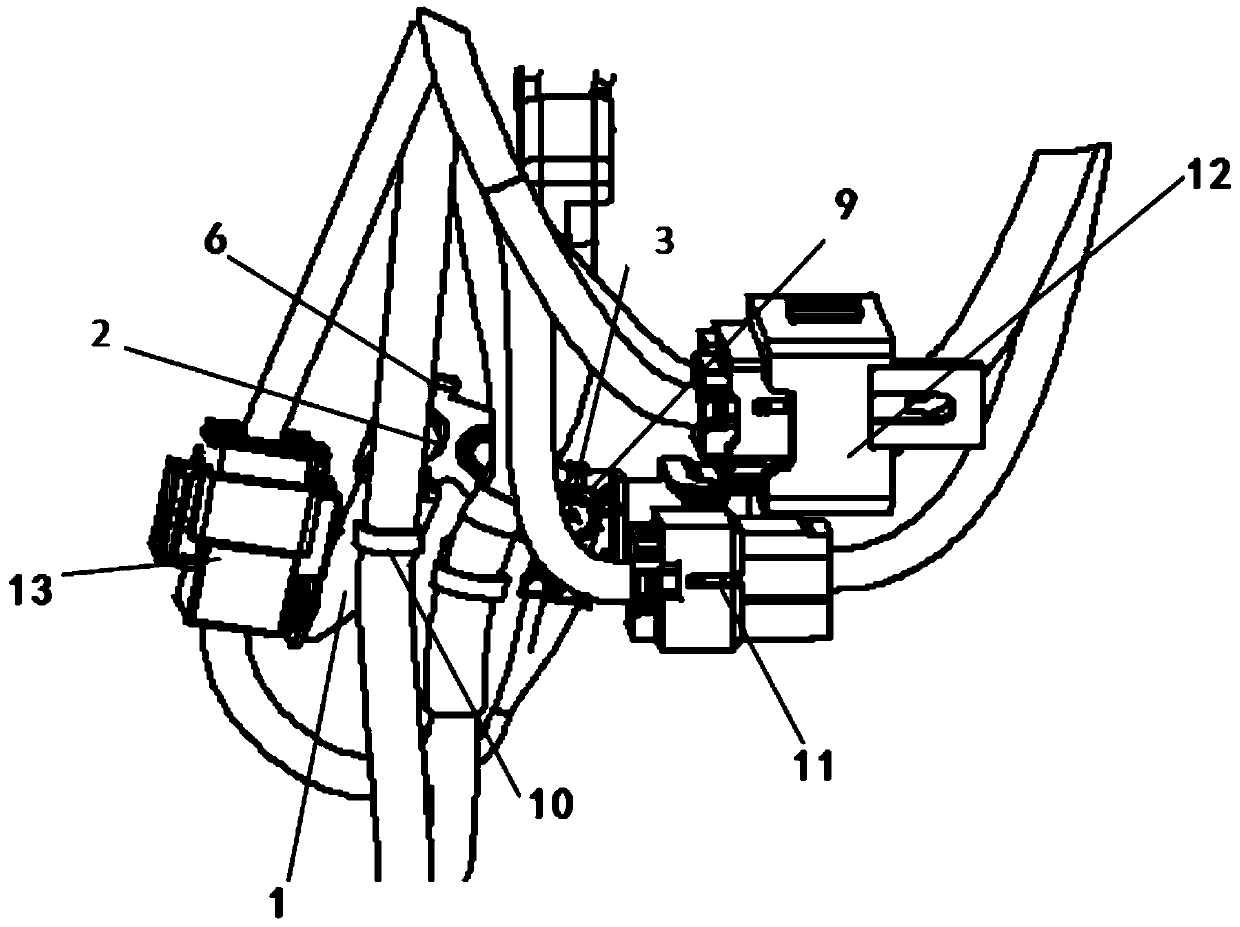

[0021] Such as Figures 1 to 2 As shown, the present invention provides a wire harness fixing bracket 1, which includes: an installation fixing surface 14 fixedly connected with the body sheet metal; and a bracket fixing surface 15 fixedly connecting the wire harness.

[0022] The invention solves the constraint problem in the prior art by providing a bracket to relatively fixedly connect the wiring harness and the vehicle body, and meanwhile, its manufacture and installation are simple and reliable.

[0023] As a preference of the present invention, the installation and fixing surface 14 is connected to the bracket fixing surface 15 through an extending connecting surface 16 . Such as figure 1 In the shown embodiment, the installation and fixing surface 14 is parallel to the bracket fixing surface 15, and the extending connection surface 16 is vertically connected to it, and there are reinforcing ribs 17 between the mutually perpendicular surfaces.

[0024] As an embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com