Light source module of flexible substrate and manufacturing method of light source module

A technology of light source modules and soft substrates, applied in the direction of light sources, point light sources, slender light sources, etc., can solve the problems of inconvenient testing and maintenance, and achieve the effect of convenient daily testing and maintenance, and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

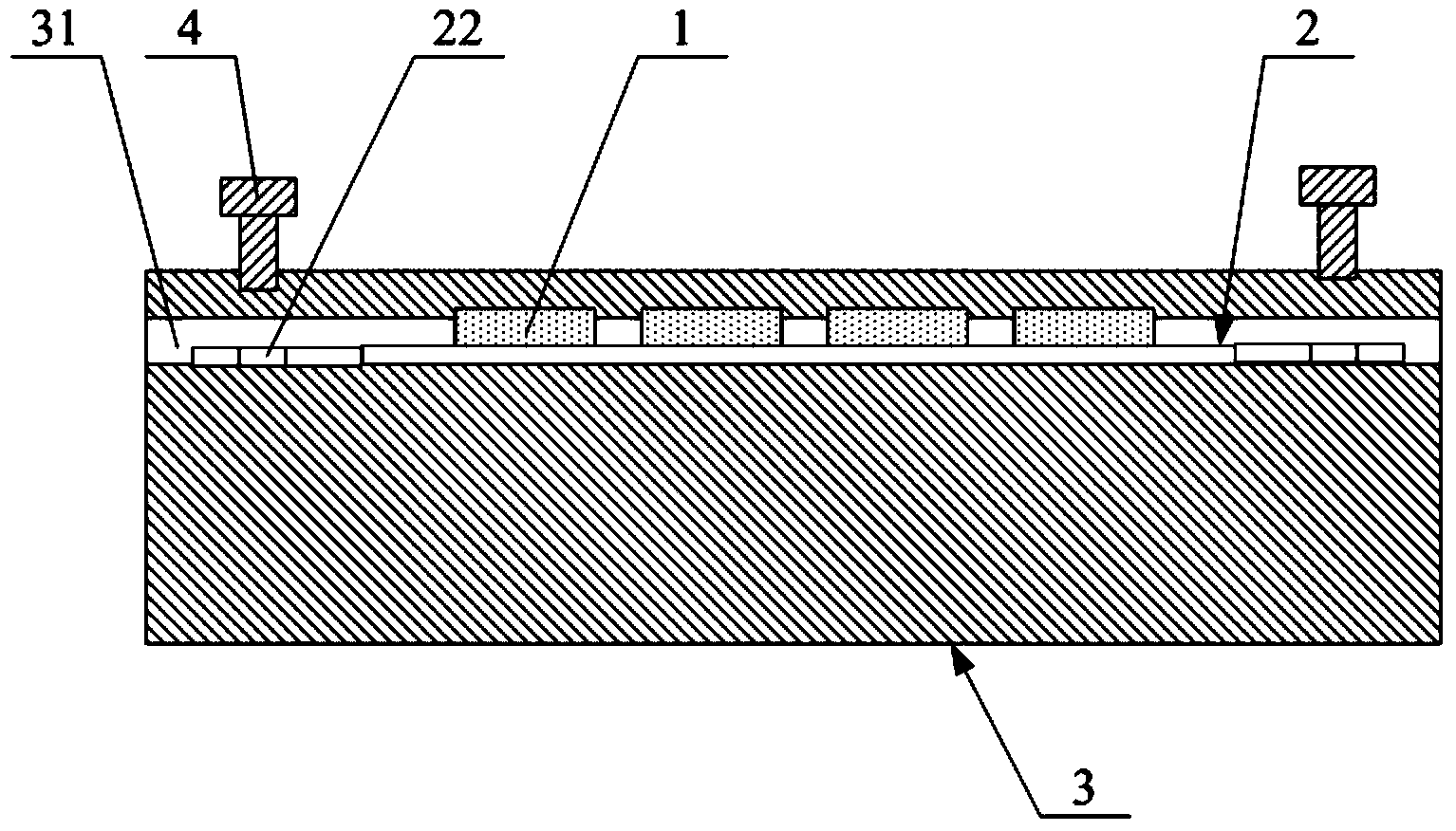

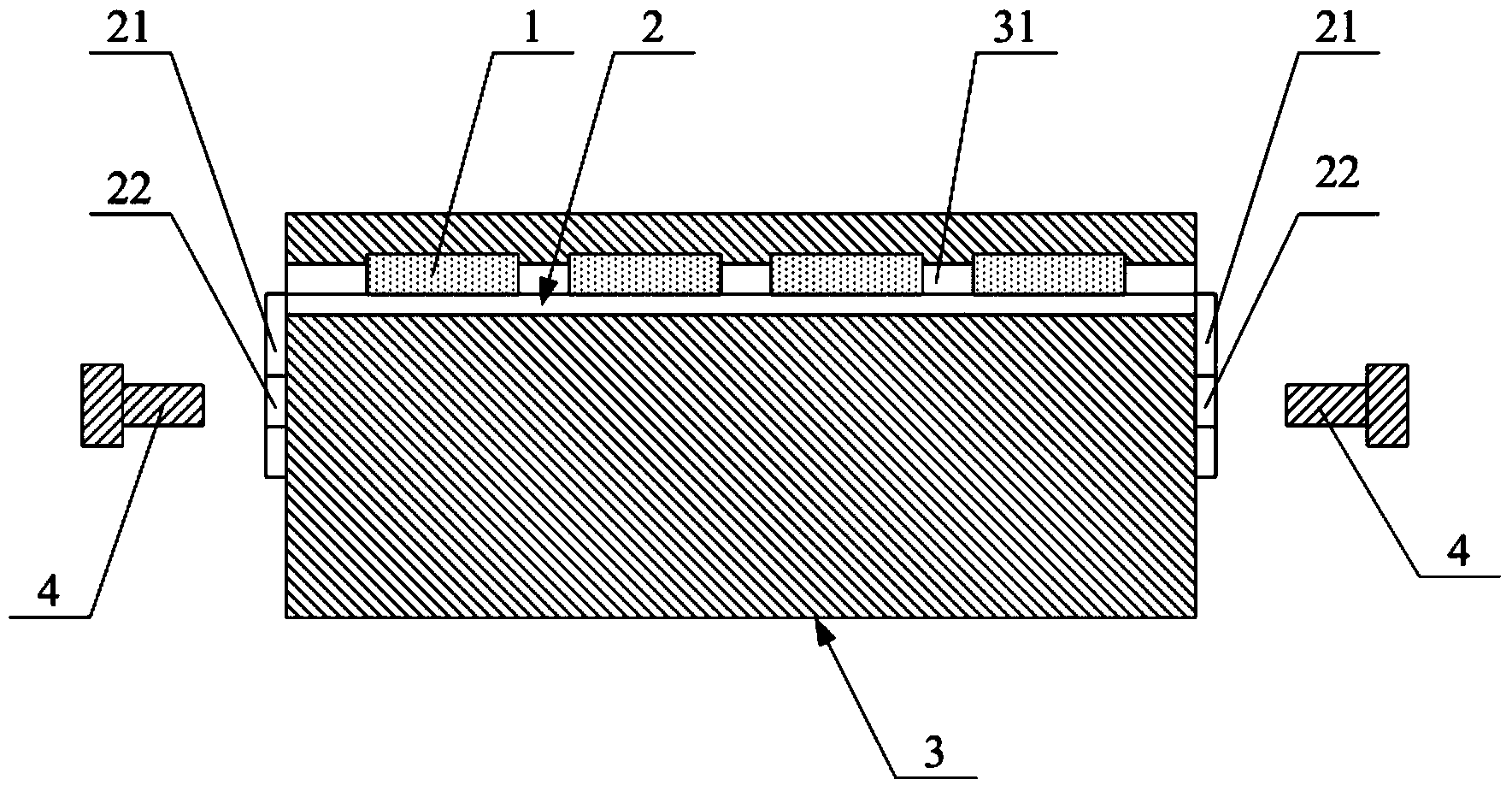

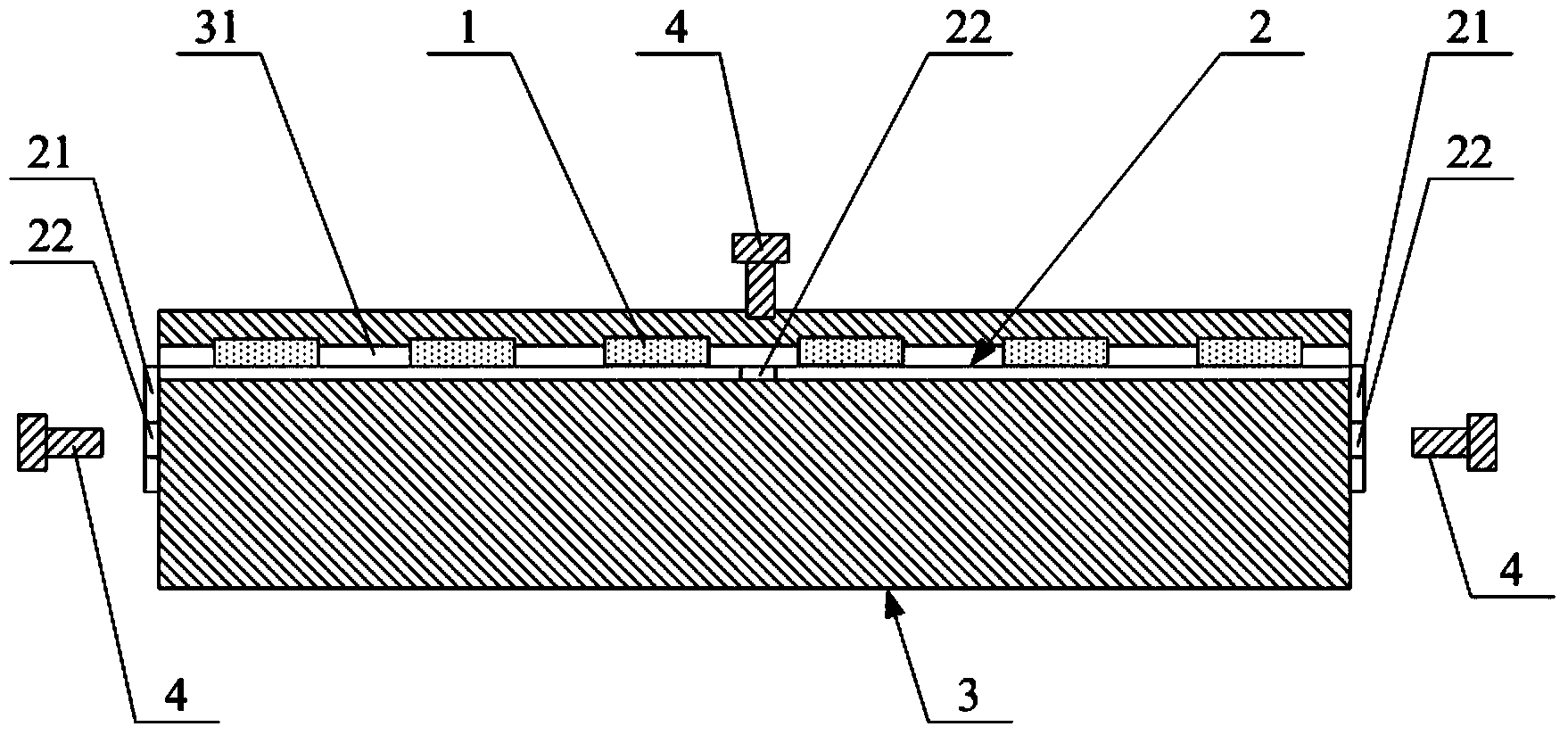

[0052] Such as Figure 1 to Figure 6 As shown, the soft substrate light source module provided in this embodiment includes: a light emitting element 1, a soft substrate 2 for installing the light emitting element 1, and a heat dissipation member 3 formed with a slot 31 for placing the soft substrate 2, and The flexible substrate 2 is fixed on the heat dissipation member 3 by fasteners 4 .

[0053] In the soft substrate light source module provided in this embodiment, firstly, the slot 31 is used to limit and fix the soft substrate 2, and then the soft substrate 2 is fixed on the heat dissipation member 3 by the fastener 4, Thus, a soft substrate light source module is formed; the installed soft substrate 2 and heat dissipation member 3 are easy to disassemble, which is convenient for daily testing and maintenance.

[0054] In this embodiment, when installing the soft substrate light source module, the soft substrate 2 needs to be installed and snapped into the card slot 31, b...

Embodiment 2

[0064] This implementation provides a method for manufacturing the soft substrate light source module in Embodiment 1, including:

[0065] Step 101, manufacturing the soft substrate;

[0066] Step 102, mounting the light-emitting element on the soft substrate;

[0067] Step 103, opening the card slot on the heat dissipation member;

[0068] Step 104 , placing the soft substrate in the slot, and fixing the soft substrate on the heat dissipation member through the fastener.

Embodiment 3

[0070] This implementation provides a method for manufacturing the soft substrate light source module in Embodiment 1, including:

[0071] Step 201, manufacturing the soft substrate;

[0072] Step 202, mounting the light-emitting element on the soft substrate;

[0073] Step 203, stamping and forming the through hole on the soft substrate;

[0074] Step 204, stamping and forming the card slot and the installation hole on the heat dissipation member;

[0075] Step 205 , placing the soft substrate in the slot, and fixing the soft substrate on the heat dissipation member through the fastener.

[0076] In this embodiment, in order to facilitate mass production, installation and production of soft substrate light source modules, a full-page soft substrate can be manufactured first, and then a plurality of light-emitting elements can be arranged on the soft substrate in the corresponding area according to actual use needs, and then the soft substrate can be installed. The substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com