Self-monitoring intelligent textile reinforced concrete and manufacturing method thereof

A fabric reinforcement and concrete technology, applied in the preparation of test samples, material resistance, etc., can solve the problems of low survival rate, low test accuracy, and the monitoring system cannot correctly respond to changes in structural parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

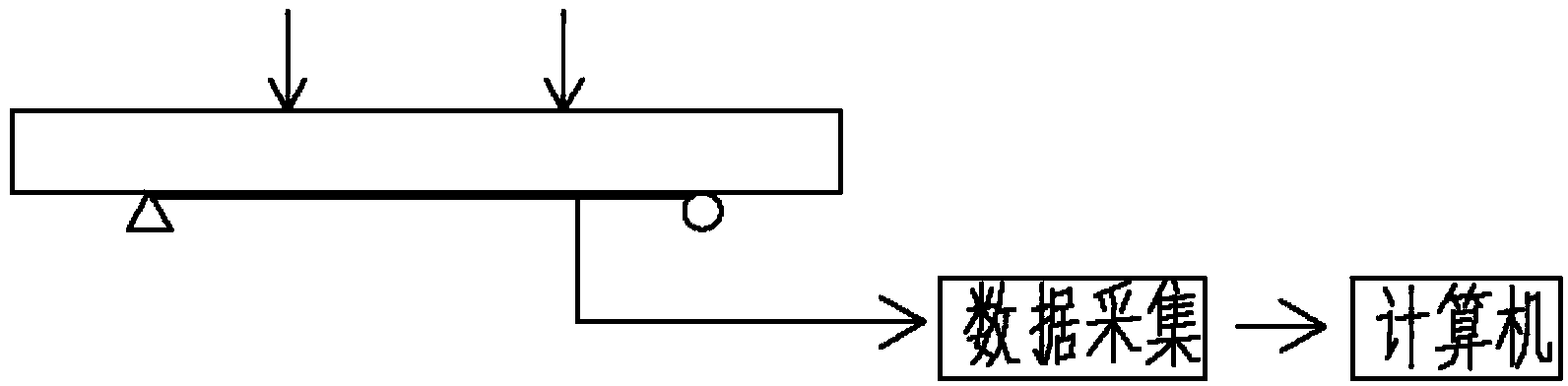

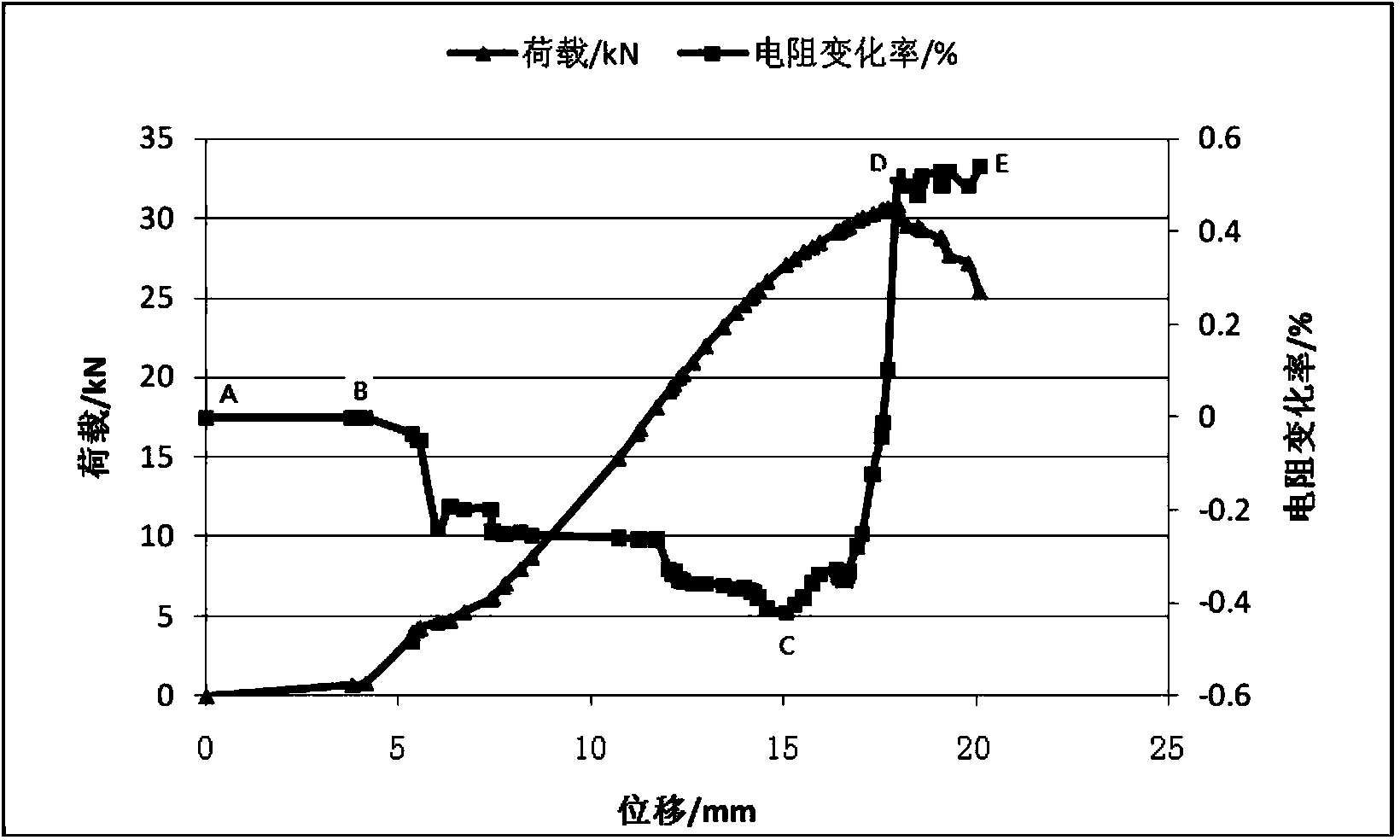

[0022] figure 1 It is the quasi-distributed test network diagram of the present invention. figure 2 It is the structural monitoring system diagram of the present invention.

[0023] A self-monitoring intelligent fabric reinforced concrete, which includes fabric mesh and electrodes; electrodes are pasted on the carbon fibers in the fabric mesh during the TRC production process; through dynamic detection of changes in the resistivity of the intelligent TRC, the stress and strain of each region in the structure Condition and distribution monitoring.

[0024] Further, the fabric net is formed by mixed weaving of carbon fiber bundles and non-alkali glass fiber bundles, the two kinds of fibers are laid vertically and horizontally to each other, and the joints are stitched with yarns.

[0025] Further, the fabric net can be laid with 3-5 layers of fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com