Atmospheric environment corrosion testing device for high sulfur natural gas purification plant

A technology for atmospheric environment and corrosion testing, applied in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of slow speed and long atmospheric corrosion exposure test cycle, achieve good technical results and reduce the number of electrodes , the effect of increasing the gas contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

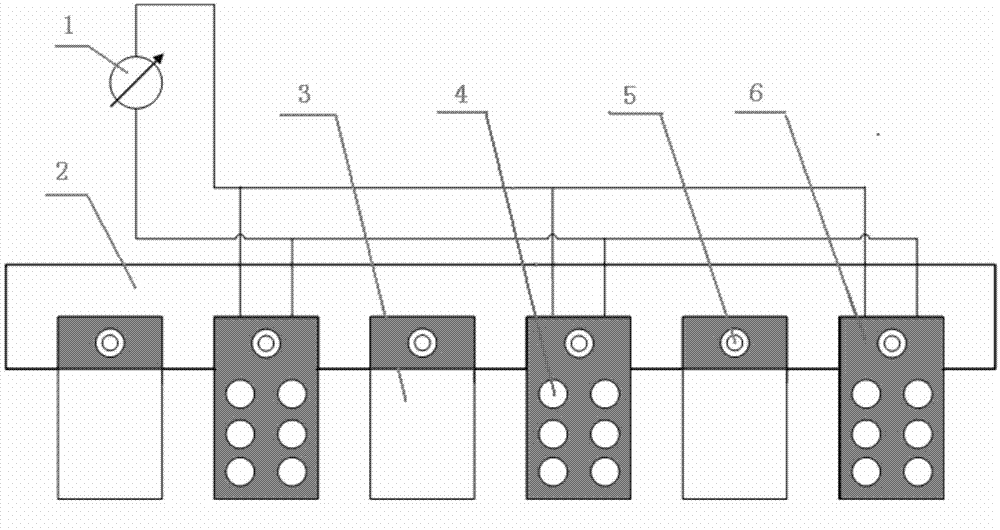

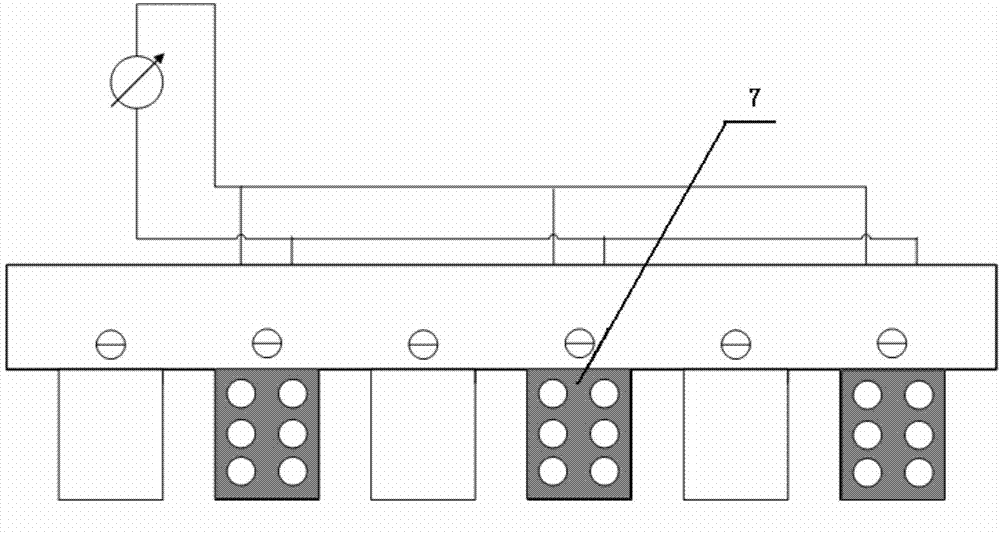

[0027] in such as figure 1 , figure 2 In the device shown, the weight loss test piece is installed on the fixed bracket through insulating bolts, the anode piece of the double-electrode primary battery, the insulating diaphragm, and the cathode piece of the double-electrode primary battery are also installed on the fixed bracket through insulating bolts, and the anode piece of the double-electrode primary battery The lead-out ends of the electrodes are respectively drawn out from the sheet and the cathode sheet, and the lead-out ends of the electrodes are electrically connected with the zero-resistance ammeter through lead wires, forming a double-electrode primary battery as a whole. The fixing bracket is mainly used to fix the atmospheric corrosion test device at the site test site. It is made of high-strength, good insulation and easy-to-process plates such as polyvinyl chloride hard plastic, polyvinyl chloride resin or high-quality glass fiber. It can be used according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com