Dual-purpose hot blast heater system with automatic material returning system for burning wood bits through spraying and burning miscellaneous trees and use method of dual-purpose hot blast heater system

A hot blast stove and material return technology, which is applied in the field of dual-purpose hot blast stove systems, can solve the problems that fuel cannot be used at the same time, and automation cannot be realized, so as to achieve the effect of realizing automation and saving operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

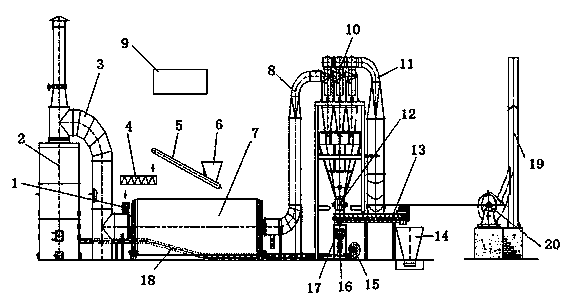

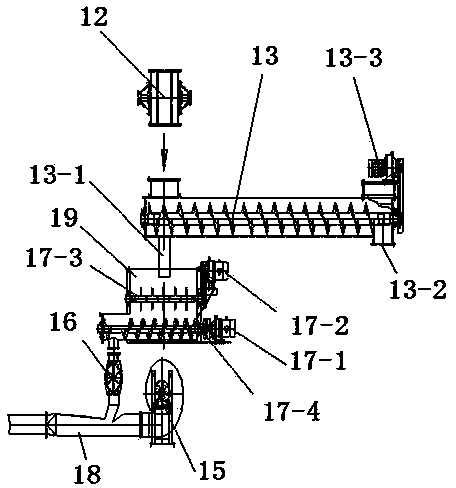

[0015] See Figure 1-5 , the specific structure is as follows:

[0016] The invention is composed of a sawdust jet burning furnace, a feeding system, a dryer, a receiving system, a discharging system, a fuel returning system and a main induced draft fan. External fuzzy control instrument.

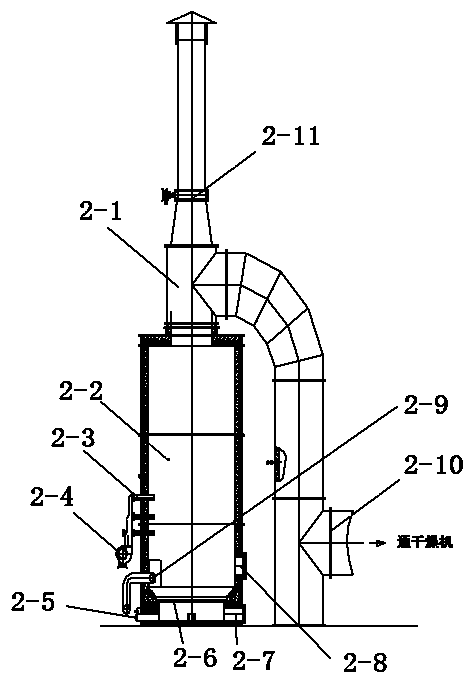

[0017] Hot blast stove body 2 (see figure 2 ) is cylindrical, with an outer diameter of about 3 meters and a height of about 8 meters. The outer skin is made of steel plates, and the inner cavity is made of refractory bricks to form a combustion space of 2-2. The space between the refractory bricks and the outer cylinder is filled with insulating materials; the upper part is provided with a flue 2-1, the lower part is equipped with a grate 2-6, the grate 2-6 is a horizontal seam grate with upper and lower layers, and the ventilation holes of the upper and lower layers of the grate 2-6 are staggered (see Figure 5 ), to prevent unburned sawdust from falling under the grate and cau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com