Leak-proof fastening device and assembly method thereof

A fastening device, leak-proof technology, applied in the field of aeronautics, can solve the problems of increasing the time and cost of installing fasteners, difficult tasks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

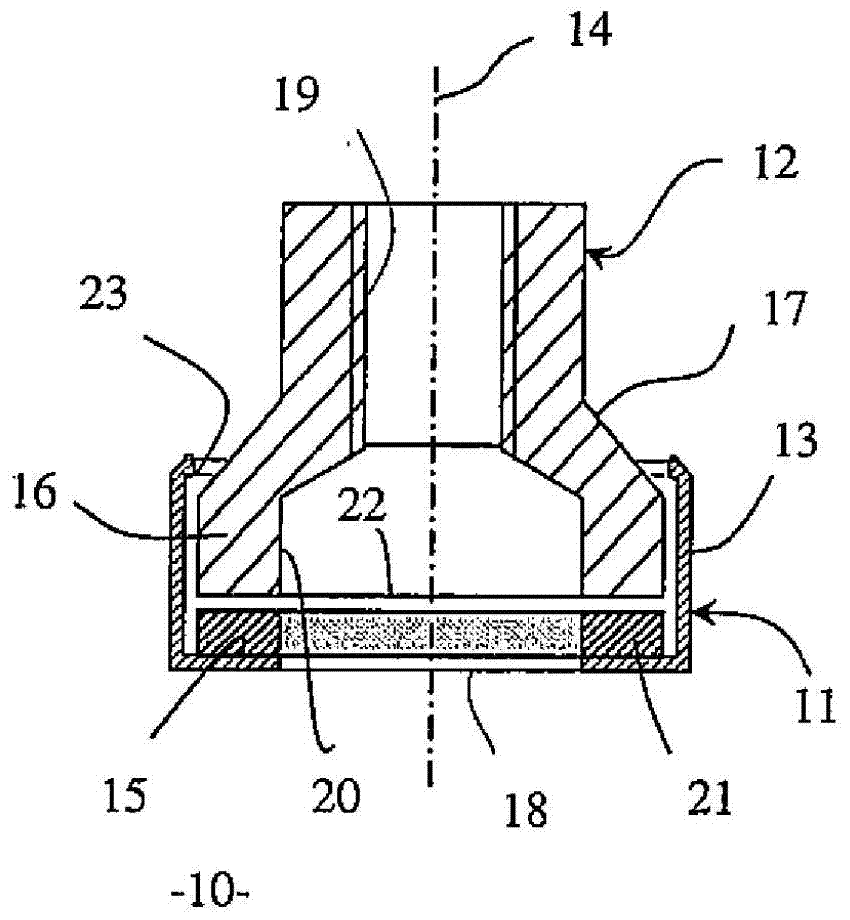

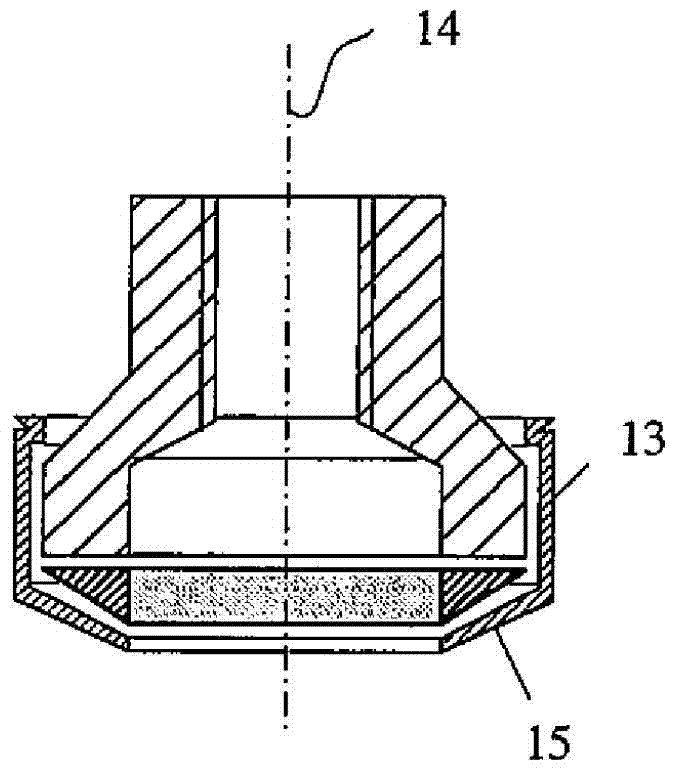

[0088] Figure 1A A cross-sectional view of an assembly according to one embodiment of the invention is shown. The assembly 10 comprises a washer 11 assembled to a fastening nut 12 .

[0089] The gasket 11 comprises an annular base 15 and a surrounding substantially cylindrical skirt 13 arranged along an axis 14 on the outer periphery of the annular base 15 .

[0090] The skirt 13 and the annular base 15 form a cavity in which the collar 16 of the fastening nut 12 is housed. The collar 16 has a substantially cylindrical shape surrounding the axis 14 . The collar 16 extends axially through a substantially frustoconical portion 17 , the diameter of which decreases the farther it is from the collar 16 along the axis 14 .

[0091] The annular base 15 has a circular aperture 18 arranged along the axis 14 . Likewise, the fastening nut 12 passes axially through the threaded hole 19 . At the collar 16 a threaded bore 19 is axially extended by a counterbore 20 having a larger diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com