Inductive hollow spiral pushing device

A kind of screw push, hollow technology, applied in the direction of pump device, rotary propeller, sealing device of piston pump, etc., can solve the problem of no push structure improvement, motor structure requirements description, etc., to improve the flow volume and push stroke, reduce Effects of noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

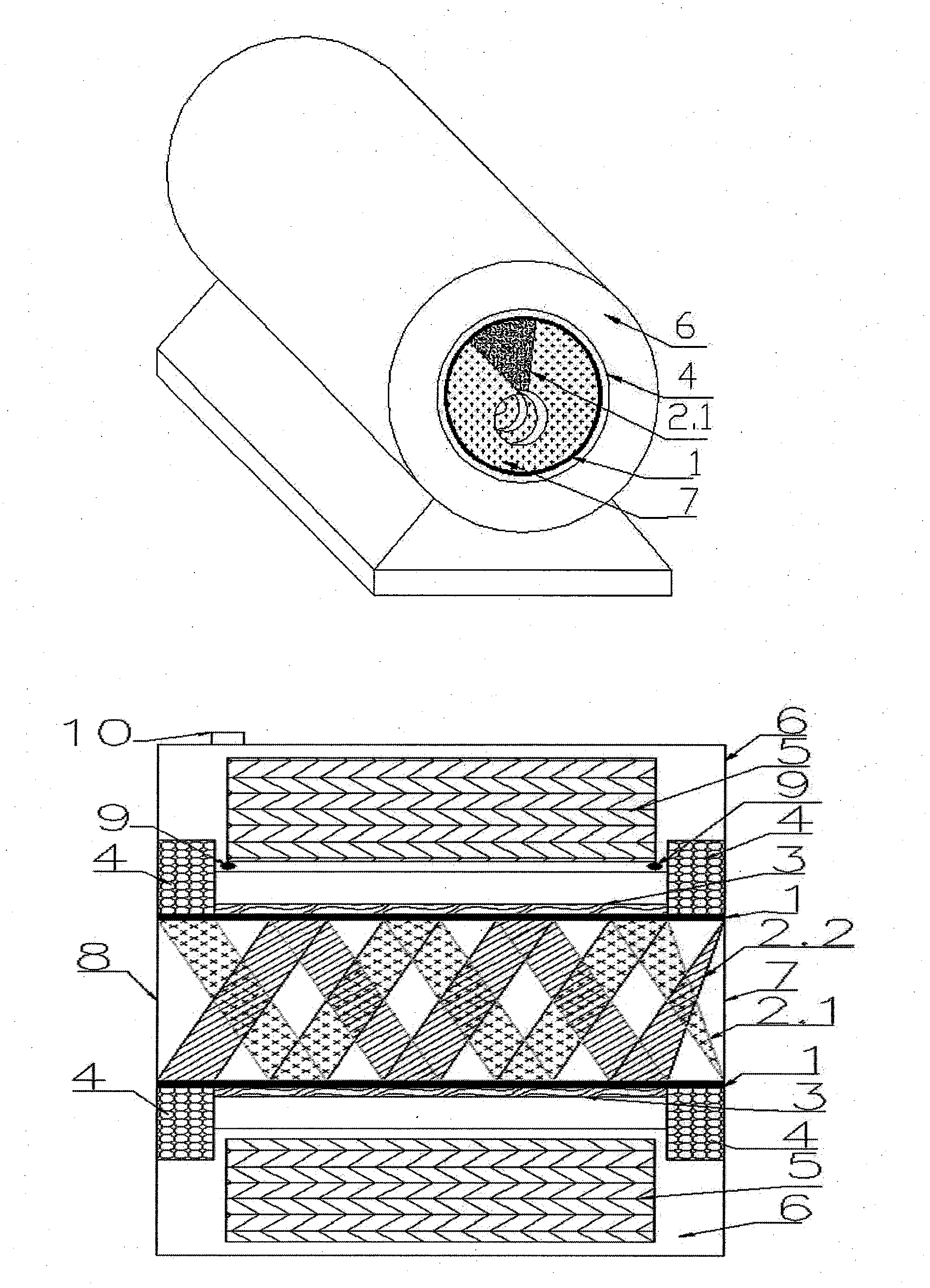

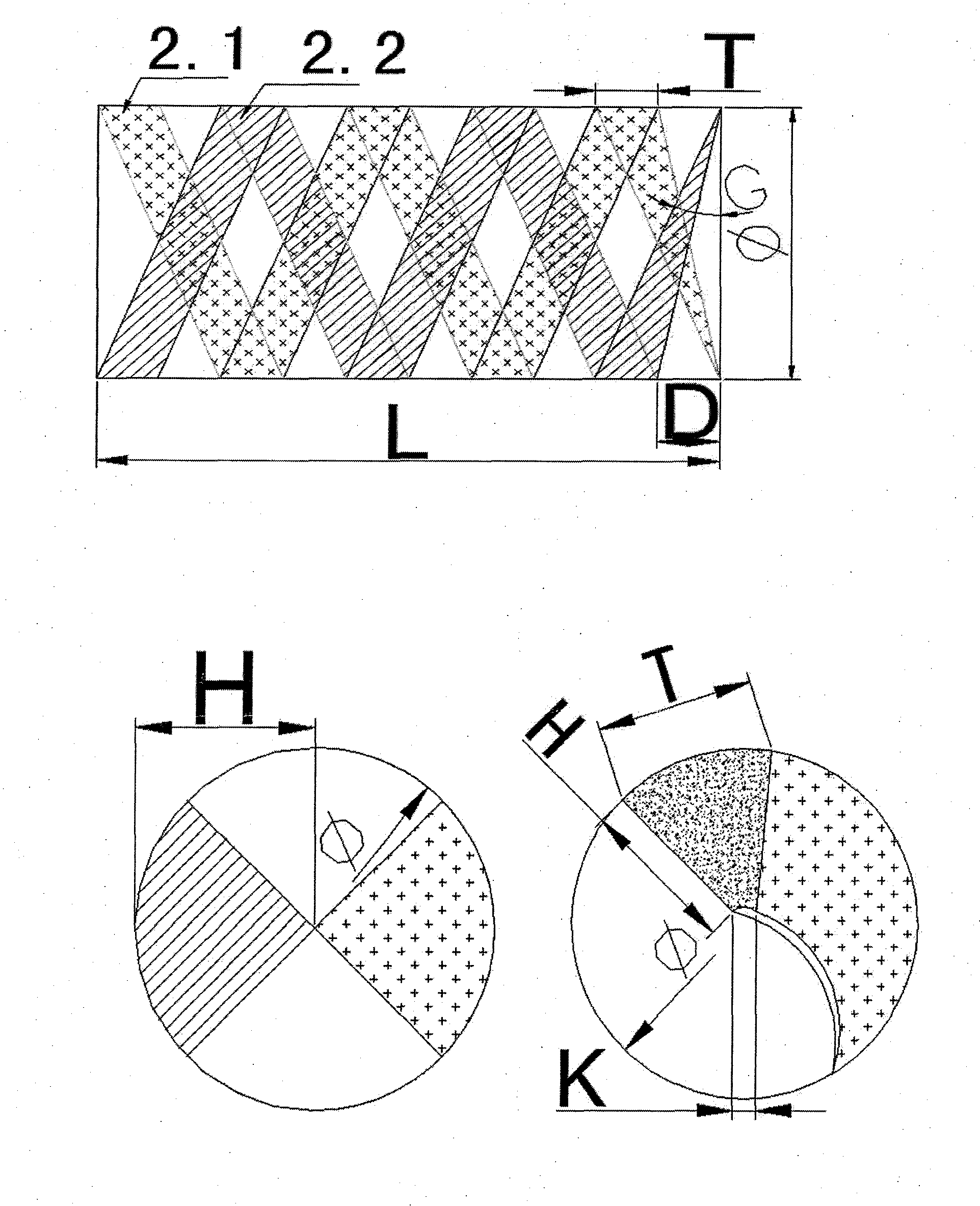

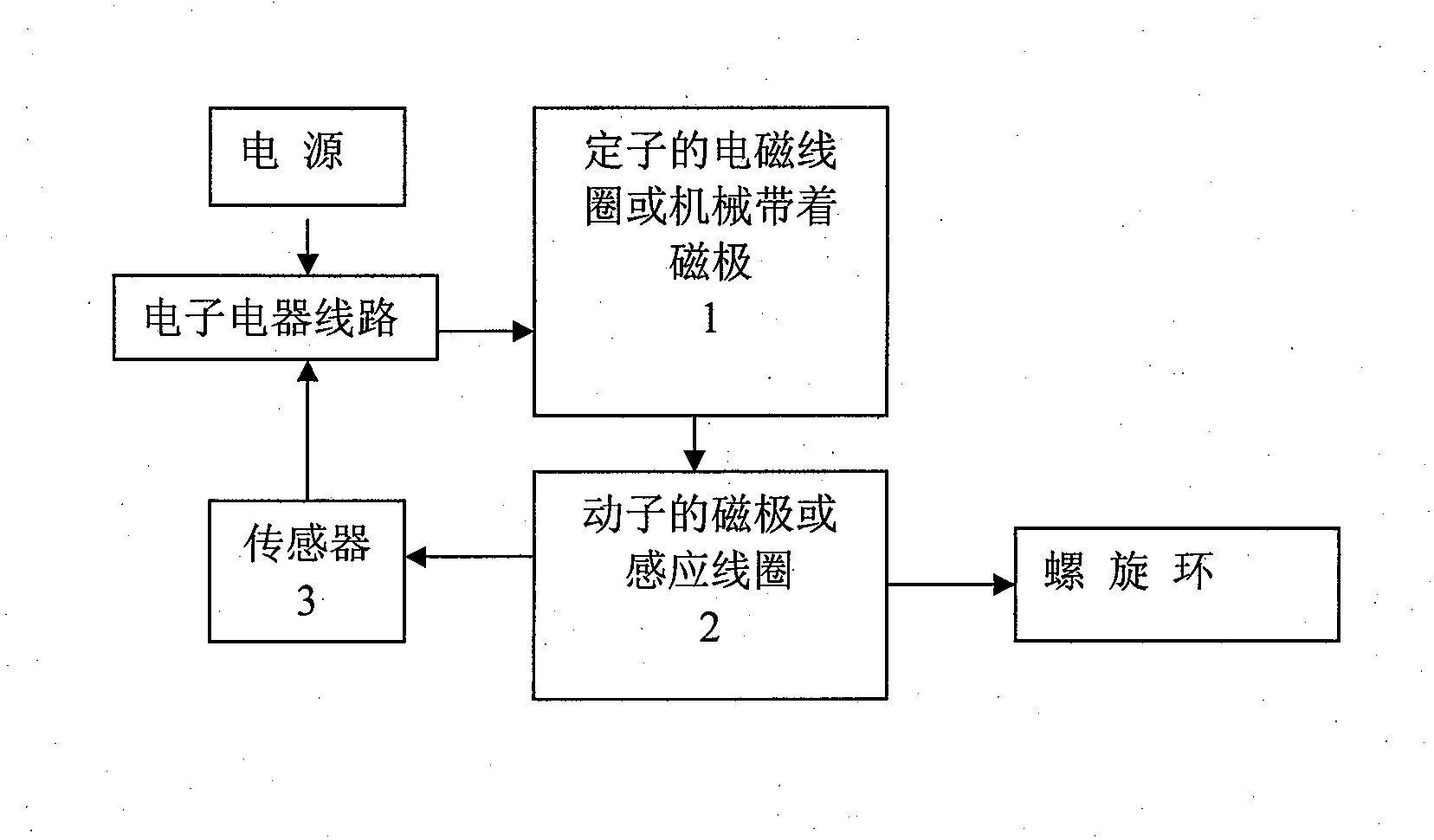

[0077] in the attached figure 1 Among the products involved in the present invention, after the integrated interface (10) is powered on, the drive block (5) in the housing (6) will immediately rotate after receiving power, default logic and instructions from the sensor (9). The magnetic field radiates around the outer wall of the central through hole. According to the principle that different poles attract each other and the same pole repels, the outer wall of the rotor (3) is immediately subjected to induced magnetic force so that the rotor (1) rotates synchronously as a whole. At the same time, the object to be pushed at the input port (7) of the casing (6) is immediately drawn in, figure 2 , the blade (K) of the spiral ring is continuously involved, along the inclined thrust surface (H) of the spiral ring, and is rotated and pushed at the root (T) of the spiral ring (2.1, 2.2), except that the thrust overcomes the length of the rotating ring The frictional force of (L) ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com