Electric control hydraulic air distribution system for engine

An electronically controlled hydraulic and engine technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the difficult valve variable function of the camshaft valve system, the insensitive response of the camshaft driven valve, and the loss of engine pump air Large and other problems, easy to achieve the braking function in the cylinder, realize the braking function in the cylinder, and reduce the effect of pump air loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

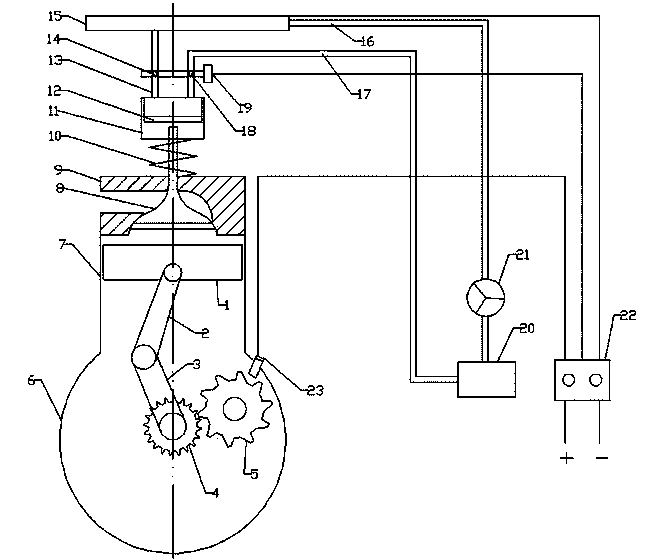

[0021] Such as figure 1 As shown, the engine electronically controlled hydraulic valve system of the present invention receives the signal from the signal plate sensor through the ECU, and controls the oil inlet and oil return of the valve mechanism, thereby controlling the movement of the piston of the valve mechanism in the hydraulic cylinder of the valve mechanism to drive the engine The valve opens or closes the intake and exhaust valves to obtain the timing and lift required by the valves.

[0022] further as figure 1 As shown, the gas distribution mechanism part specifically includes a hydraulic cylinder block 11 and a hydraulic piston 12. The hydraulic piston 12 can move up and down in the hydraulic cylinder bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com