Milling and forming system of gravity type wharf foundation bed and construction method of gravity type wharf structure

A technology of gravity wharf and construction method, which is applied in the direction of coastline protection, jetty, pier, etc., can solve the problem of rapid construction of islands and reefs that cannot be adapted to efficient, fast, and large-scale construction, and low construction efficiency of bored piles. There are many auxiliary work procedures, etc., to achieve the effect of high construction work efficiency, high mechanical work efficiency, and good component installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

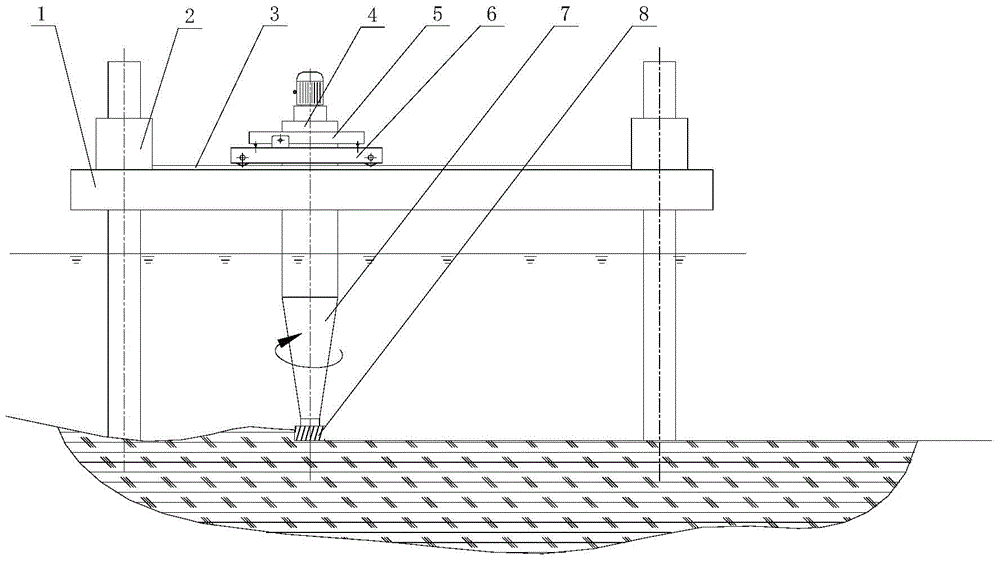

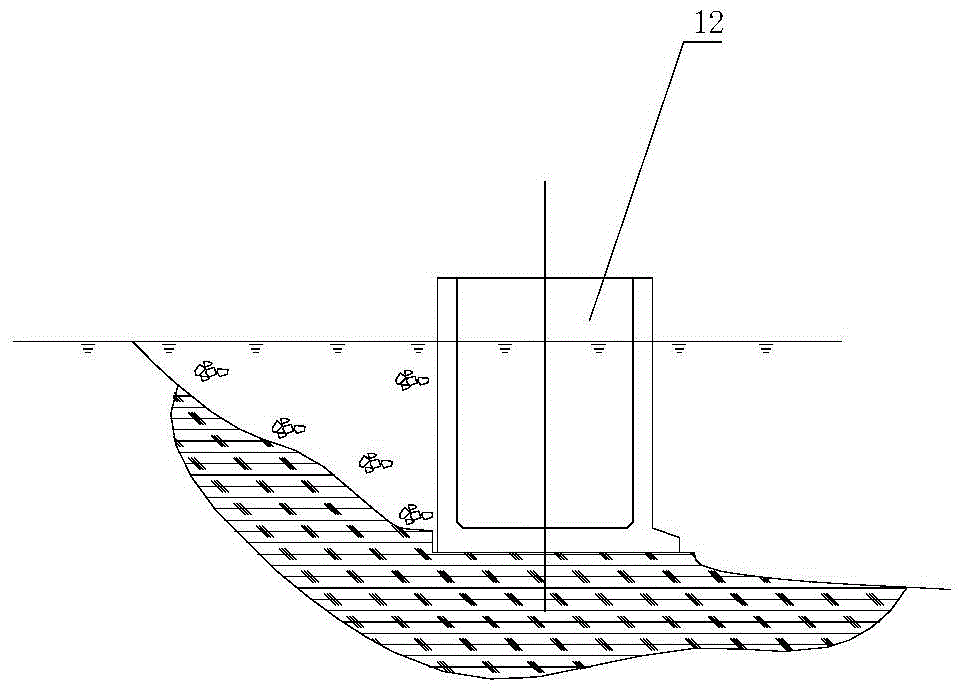

[0037] Now in conjunction with the accompanying drawings, the gravity type wharf bedding milling forming system and the milling forming method of the gravity type wharf bedding of the present invention will be described.

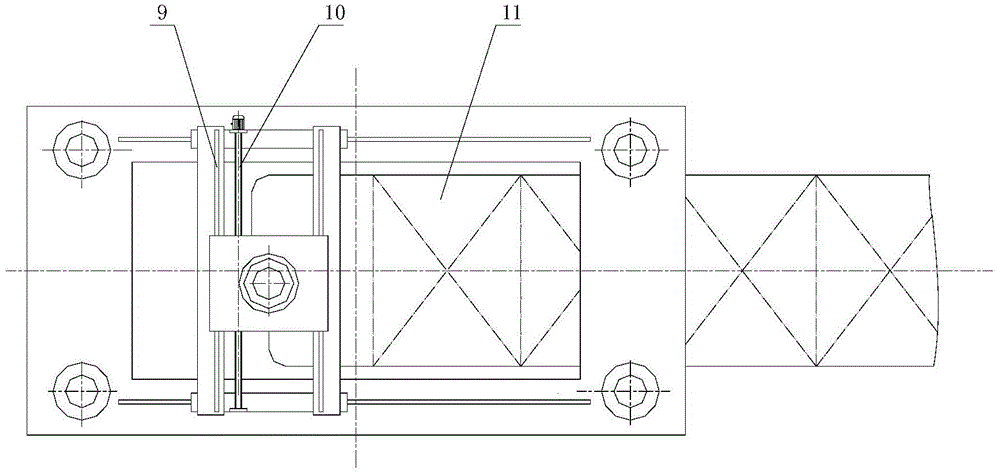

[0038] First install as figure 1 and figure 2The milling and forming system for the heavy-duty dock bed shown. The above-water construction platform 1 is positioned on the foundation bed to be milled through the supporting legs 2. The above-water construction platform 1 is equipped with a longitudinal movement track 3 for the mobile trolley 6 to move longitudinally, and the mobile trolley 6 is equipped with a transverse Track 9, for milling trolley 5 can carry out milling feeding of transverse movement. The bottom of the milling trolley 5 extends a milling machine tool bar 7 toward the seabed, and a milling tool head 8 is installed at the bottom of the milling machine tool bar 7, and the milling machine tool bar 7 can move in the vertical direction. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com