Two-way trailer wagon for railway ballast bed operation device

An operating device and two-way traction technology, which is applied in track cleaning, construction, cleaning methods, etc., can solve problems such as difficulty in adapting the device, affecting operation quality and efficiency, and jumping, so as to improve operation quality, ensure normal operation, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

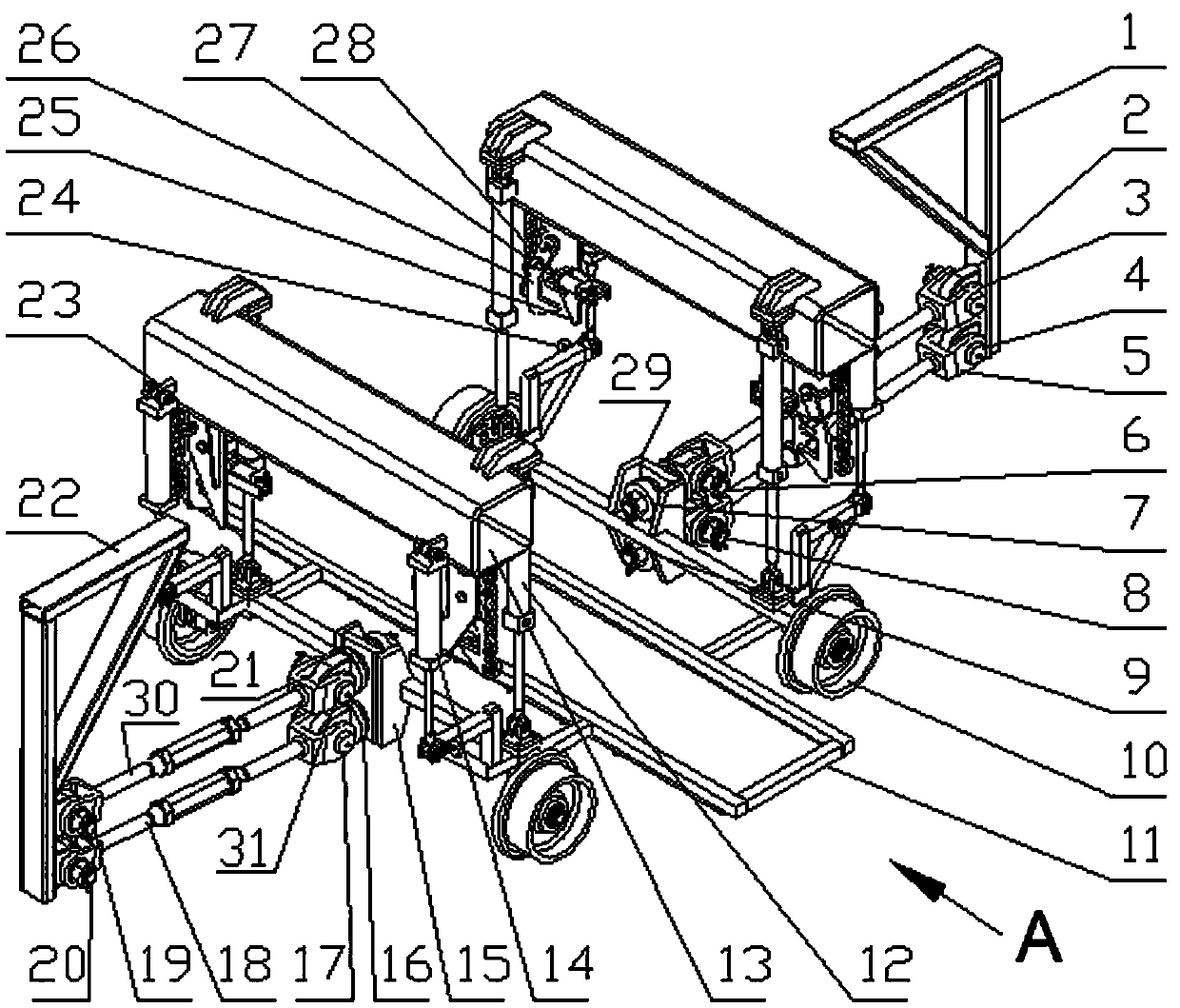

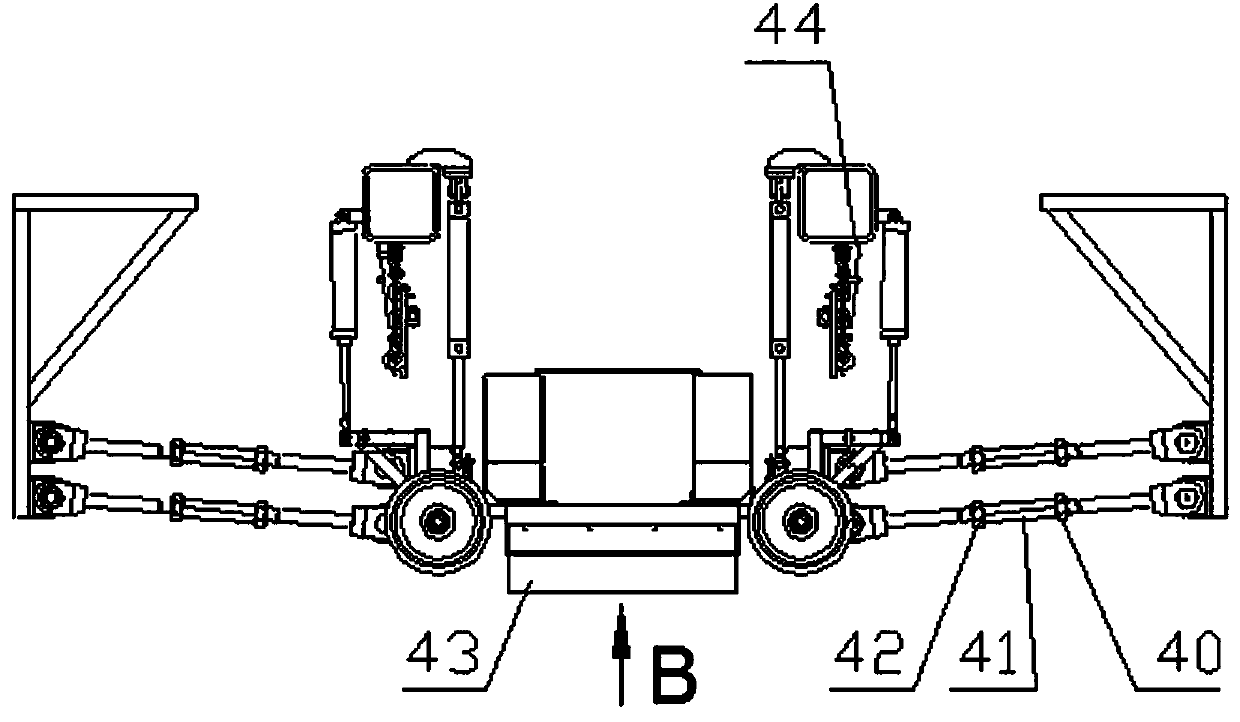

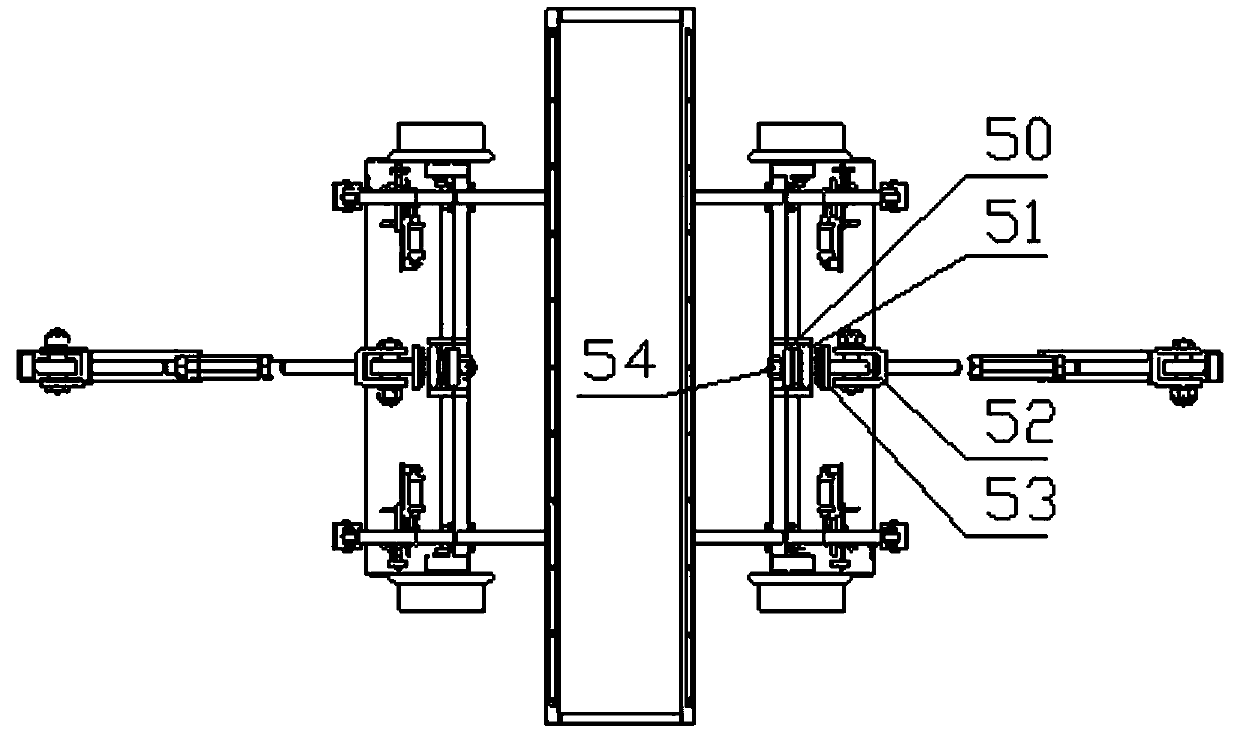

[0048] Example 1.1 , the present embodiment provides a two-way traction trolley for a railway track bed operating device, which includes a trolley bracket 11, four trolley wheels 10 are installed below the trolley bracket 11, two frame bottom beams 13 are installed above the trolley bracket 11, and the trolley The front of the support 11 is connected to the right support frame 1 by the upper right drawbar 3 and the lower right drawbar 5, and the rear of the trolley support 11 is connected to the left support frame 22 by the upper left drawbar 30 and the lower left drawbar 18. The front is equipped with a right traction support fixed mount 29, which connects the front of the trolley support 11 with the upper right drawbar 3 and the lower right drawbar 5, and the rear of the trolley support 11 is equipped with a left traction support fixed Frame 15, the left traction support fixed frame 15 connects the rear of the trolley bracket 11 with the left upper drawbar 30 and the left l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com