Method for improving lincomycin yield by fed-batch cultivation

A technology of lincomycin and yield, which is applied in the field of microbial fermentation, can solve problems such as adverse effects, achieve the effect of increasing potency and prolonging the fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

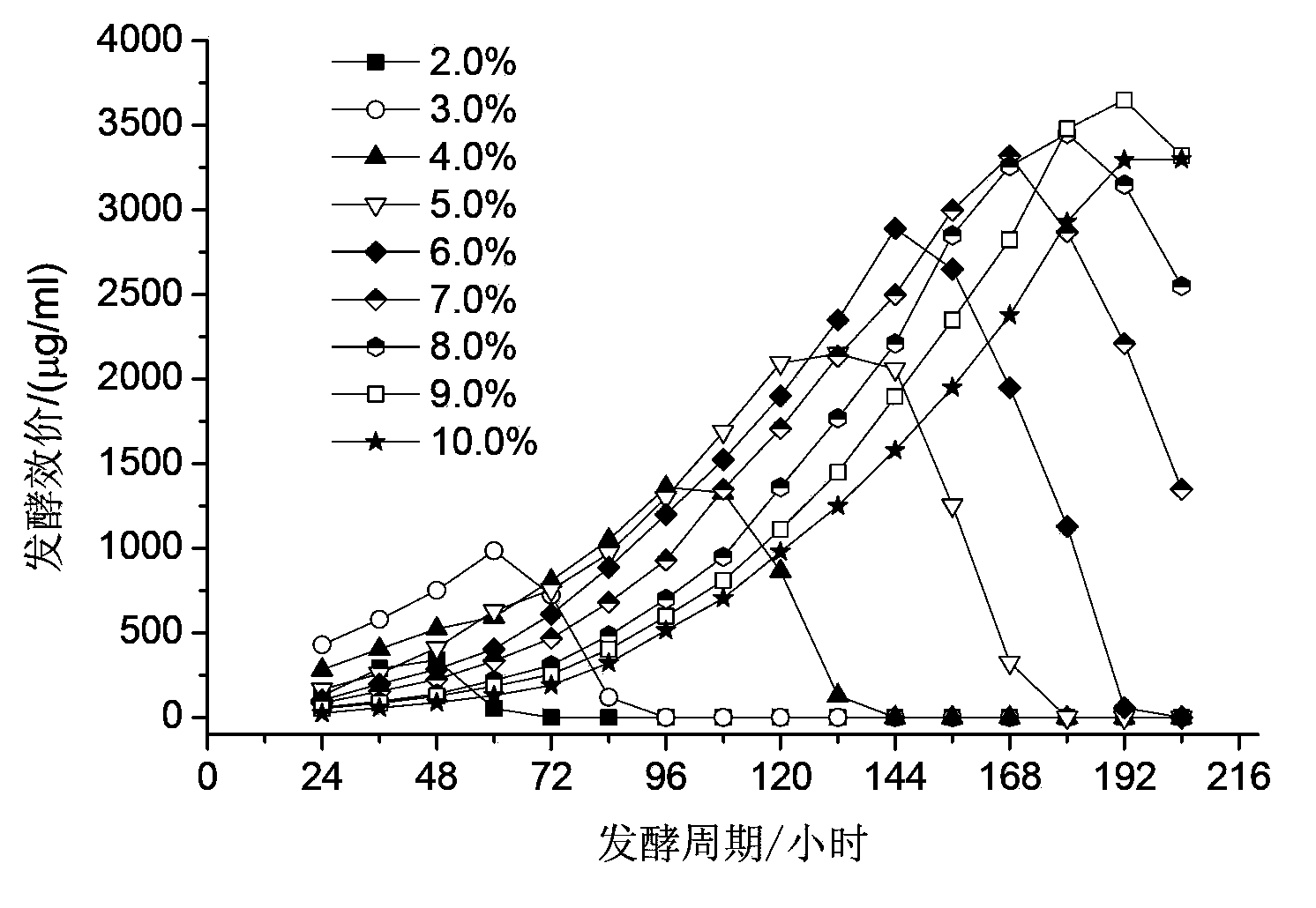

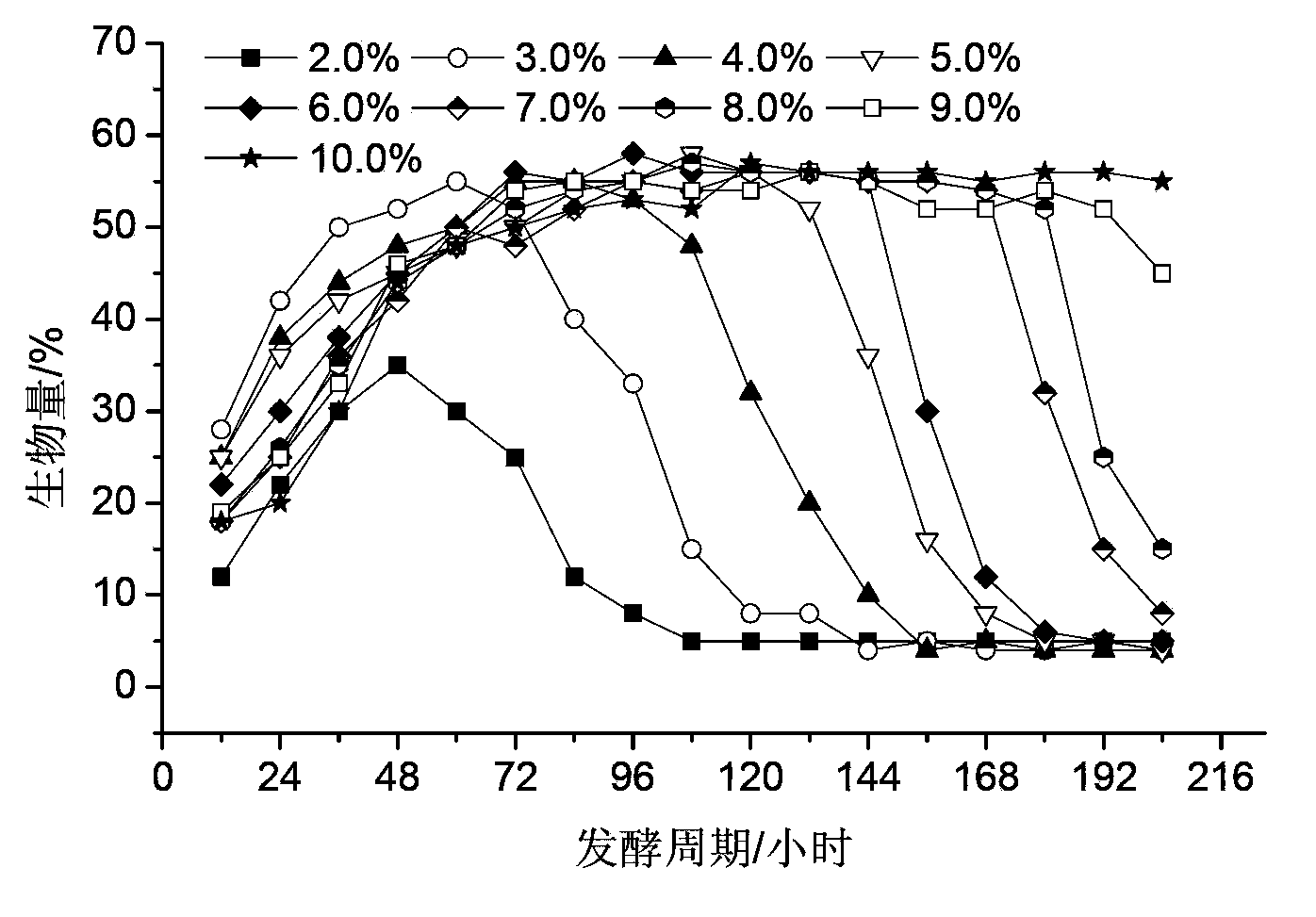

[0043]Example 1: Effects of glucose content on lincomycin fermentation titer, bacterial concentration and pH in shake flask fermentation

[0044] In the shake flask fermentation formula, under the condition of not changing other components, glucose with content of 2.0%, 3.0%, 4.0%, 5.0%, 6.0%, 7.0%, 8.0%, 9.0%, 10.0% was used as carbon source , to investigate the changes of lincomycin resistance level, biomass and pH in different fermentation cycles. from figure 1 , 2 , 3. It can be seen that because high concentration of sugar has a certain inhibitory effect on the growth of bacteria, the higher the initial glucose content in the medium, the slower the growth of the producing bacteria, and the initial resistance level of lincomycin is also correspondingly inhibited , which is mainly due to the lower biomass in the early stage and the glucose effect that exists when the sugar concentration is high. As the sugar in the medium is slowly utilized, when the concentration of res...

Embodiment 2

[0045] Example 2: Investigate the influence of dissolved oxygen on the fermentation titer of lincomycin in shake flask fermentation

[0046] In shake-flask fermentation, the effect of dissolved oxygen on the level of fermentation resistance was investigated mainly by changing the rotating speed of the shaker and the amount of liquid in the shake-flask. Under the condition that the amount of shaking bottle is 100ml / 750ml, the rotating speed of the shaking table is set to 150 rev / min, 180 rev / min, 200 rev / min, 220 rev / min and 250 rev / min respectively. At the same time, under the condition that the shaker speed is 250 rpm and the inoculum size is consistent, the liquid volume of the shaker bottle is 50ml / 750ml, 80ml / 750ml, 100ml / 750ml, 120ml / 750ml , 150ml / 750ml to investigate the fermentation titer of lincomycin in different cycles. from Figure 4 , 5 It can be seen that the higher the rotation speed of the shaker, the higher the level of resistance to lincomycin in the same c...

Embodiment 3

[0047] Embodiment 3: the application of fed-batch technology in 200L fermenter

[0048] The initial glucose content of the culture medium determined according to Example 1 was 3.0%. At the same time, according to Example 2, in the process control of the fermenter, by adjusting the stirring speed of the fermenter, the air flow rate and the feeding process in the middle and later stages to maintain a higher dissolved oxygen, it is beneficial to the improvement of the level of lincomycin production and resistance.

[0049] Fermenter basal medium (%): starch 0.5, glucose 3, cold-pressed soybean powder 0.9, compound protein powder 0.6, corn steep liquor 1.5, (NH 4 ) 2 SO 4 0.4, NaNO 3 0.4, NH 4 NO 3 0.4, NaCl0.5, KH 2 PO 4 0.05, CaCO 3 0.8, bubble enemy 0.035, silicone oil 0.025, pH6.5~7.5, sterilized at 121℃ for 30min.

[0050] Dilute medium (%): corn steep liquor 15.0, cold-pressed soybean powder 6.0, compound protein powder 4.0, CaCO 3 0.6, bubble enemy 0.1, silicone o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com