A high-precision supply method and equipment for germanium tetrachloride

A germanium tetrachloride, high-precision technology, applied in the direction of glass manufacturing equipment, manufacturing tools, etc., can solve problems such as the method of precise flow control that is not mentioned, and achieve the effects of reducing parameter fluctuations and scrapping, compact structure, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

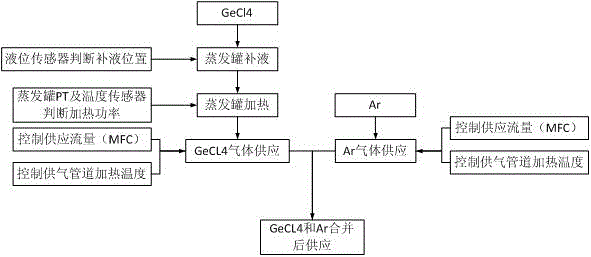

Method used

Image

Examples

Embodiment Construction

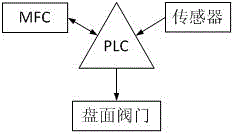

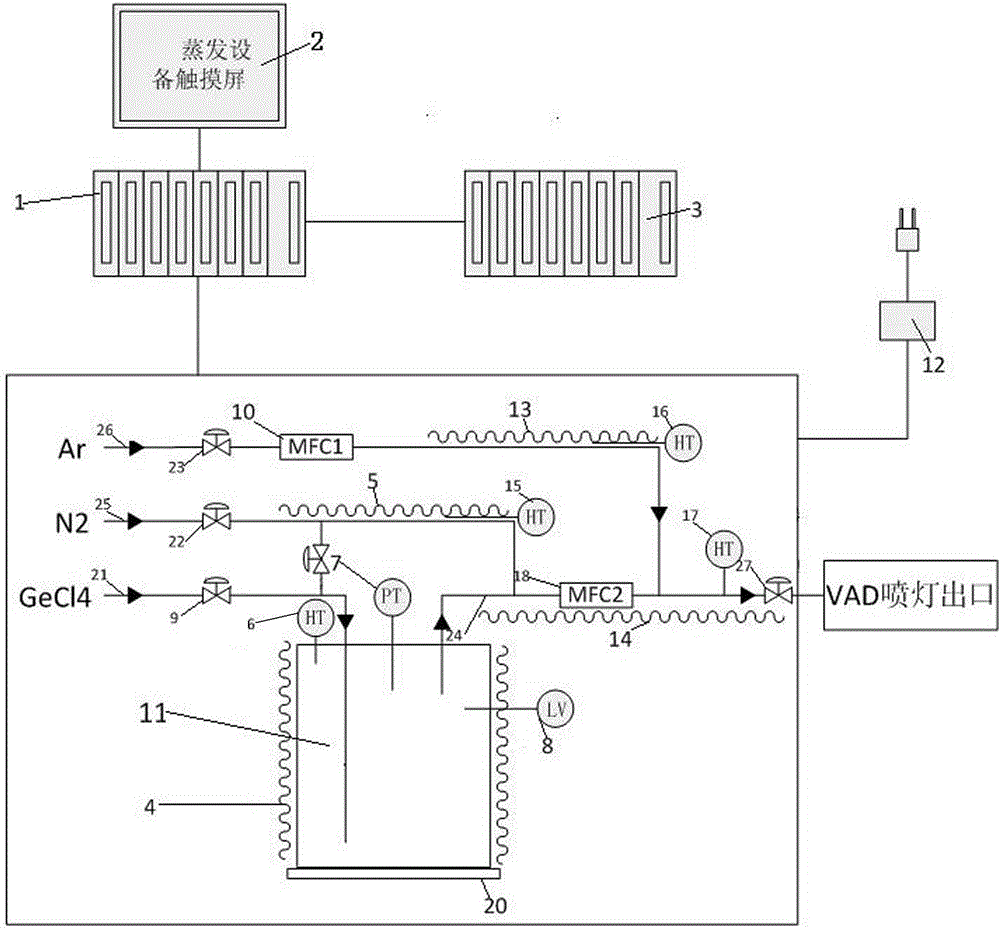

[0027] Refer to attached Figure 1~3 , a germanium tetrachloride high-precision supply equipment includes evaporation equipment programmable controller PLC1, evaporation equipment touch screen 2, VAD equipment PLC 3, heating zone one 4, heating zone two 5, heating zone three 13, heating zone four 14 , temperature sensor one 6, temperature sensor two 15, temperature sensor three 16, temperature sensor four 17, pressure sensor 7, liquid level sensor 8, control valve one 9, control valve two 22, control valve three 23, mass flow controller one 10. Mass flow controller II 18. Evaporation tank 11. Power supply 12.

[0028] The evaporation tank 11 is provided with a liquid level sensor 8, a pressure sensor 6, a temperature sensor 6 and an electronic scale 20 for monitoring the condition of the tank body; an electronic scale 20 is provided at the bottom of the evaporation tank to monitor the weight in real time. A heating belt 4 is arranged on the outside, a GeCl raw material liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com