Regeneration process of operating fluid for producing hydrogen peroxide by anthraquinone method

A working fluid, hydrogen peroxide technology, applied in the directions of peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, chemical instruments and methods, chemical recovery, etc., to improve regeneration effect, prolong service life, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

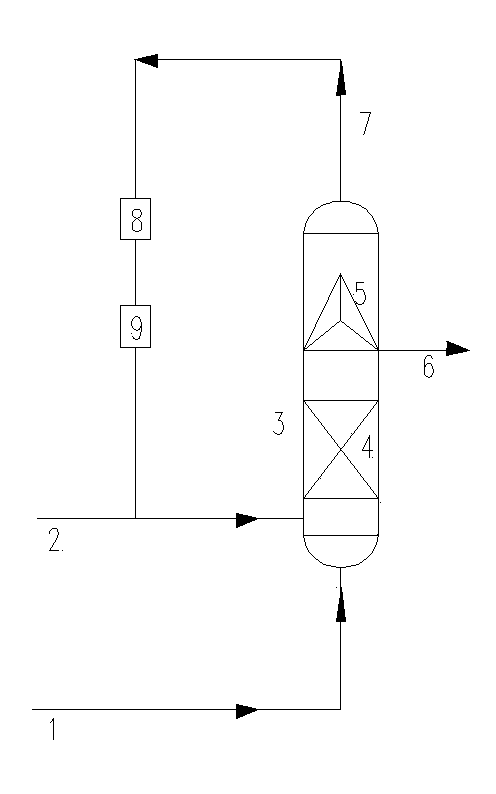

Image

Examples

Embodiment 1

[0023] The regeneration pressure is normal pressure, the regenerative bed is γ-alumina, the temperature of nitrogen is 65°C, nitrogen (Nm 3 / h) and the volume flow ratio of the post-treatment working fluid is 1:125, and the gas-liquid parallel flow (from bottom to top) of the material enters the regeneration bed for regeneration reaction. After treatment by this method, the total anthraquinone content of the working fluid was 138g / L, and the total degradation product content was 30g / L. The regeneration effect began to decline after 102 days of continuous operation, and the regeneration bed lost its regeneration effect after 115 days.

Embodiment 2

[0025] The regeneration pressure is normal pressure, the regenerative bed is γ-alumina, the temperature of argon is 78°C, and the argon (Nm 3 / h) and the volume flow ratio of the post-treatment working fluid is 1:13.3, and the gas-liquid counterflow of the material (argon from top to bottom, post-treatment working fluid from bottom to top) enters the regeneration bed for regeneration reaction. After being treated by this method, the total anthraquinone content of the working solution is 140g / L, and the total degradation product content is 28g / L. After 110 days of continuous operation, the regeneration effect began to decline, and after 125 days, the regeneration agent was inactivated.

Embodiment 3

[0027] The regeneration pressure is normal pressure, the regeneration bed is silicon dioxide, the temperature of nitrogen is 65°C, nitrogen (Nm 3 / h) and the volume flow ratio of the post-treatment working fluid is 1:66.7, and the gas-liquid parallel flow (from bottom to top) of the material enters the regeneration bed for regeneration reaction. After being treated by this method, the total anthraquinone content of the working solution was 142g / L, and the total degradation product content was 26g / L. The regeneration effect began to decline after 135 days of continuous operation, and after 153 days of regenerant life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com