A CNC gantry planer

A gantry planer and control unit technology, applied in the direction of planer, planer/slotting machine, metal processing equipment, etc., can solve the problems of poor stability, low work efficiency, low service life, etc., achieve good stability, improve work efficiency, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

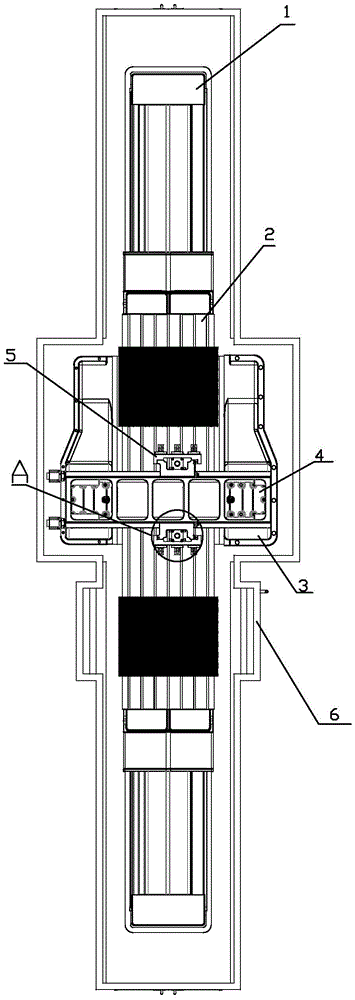

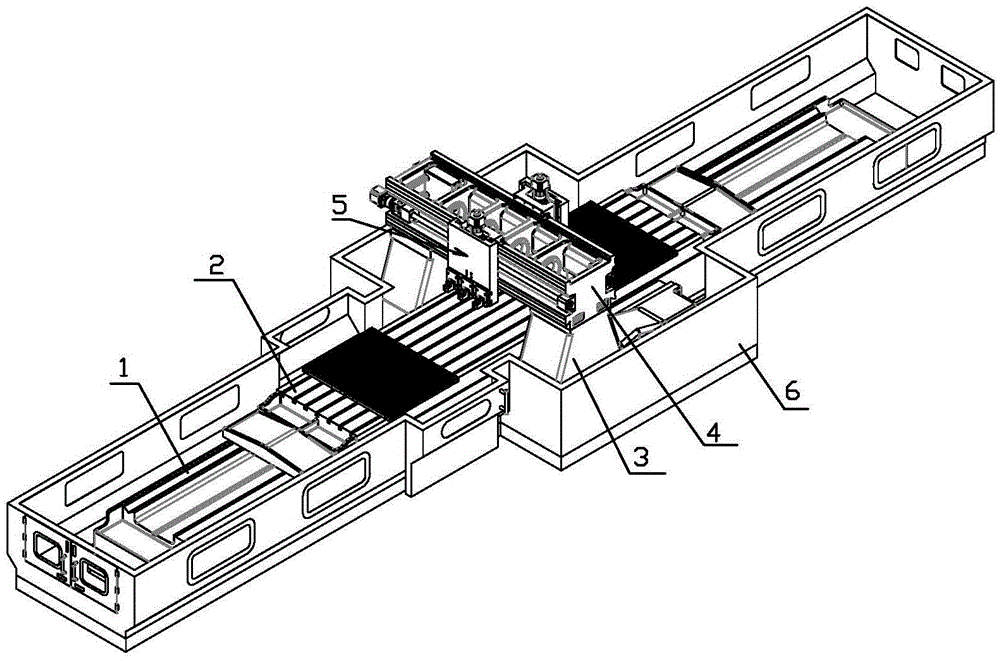

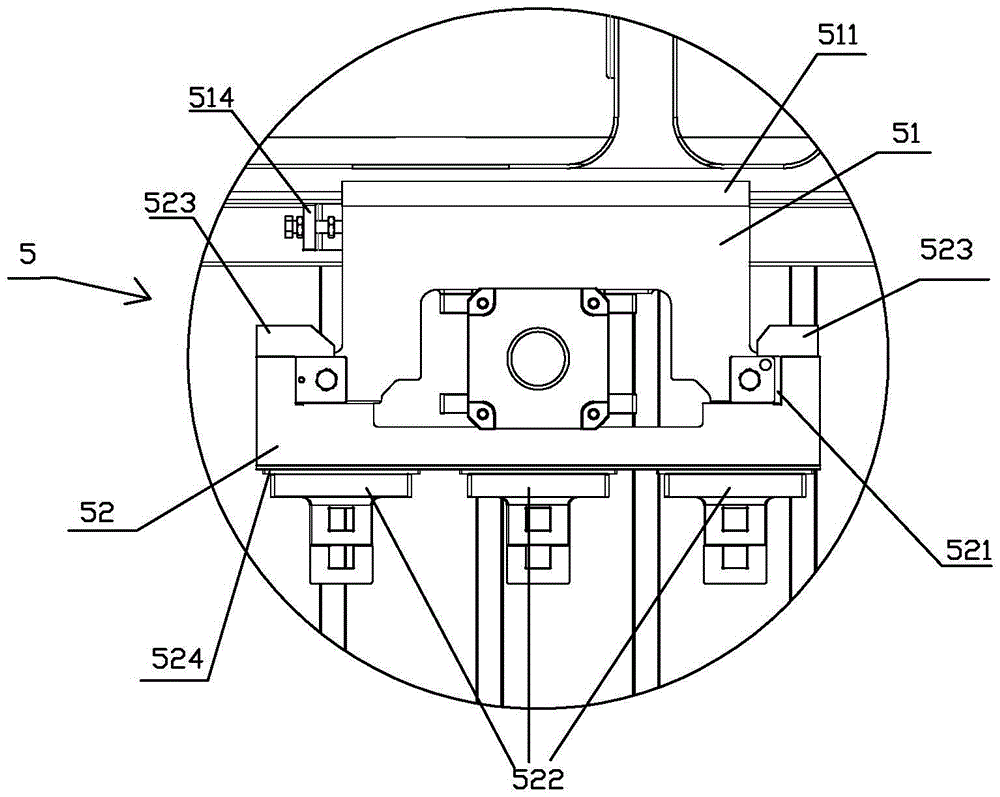

[0022] Embodiment: a kind of numerical control gantry planer, comprises gantry planer base 1, carriage 2, two left and right columns 3, crossbeam 4 and control unit, such as Figures 1 to 4 As shown, the beam 4 is fixedly arranged on the two columns 3; the motor A and the screw A are installed on the planer base 1, and the screw A is longitudinally installed on the planer base 1 through the bearing and the bearing seat. , the vertical direction refers to figure 1 In the up and down direction, the screw mandrel A is threadedly connected with a screw nut, and the screw nut is arranged on the carriage 2 through a nut seat, the motor A is connected to the screw rod A in transmission, and the motor A is connected to the control unit; the shape of the beam 4 is A cuboid, a guide rail is respectively arranged horizontally on the front and the rear of the crossbeam 4, and the horizontal direction refers to figure 1 In the left and right directions, the front of the beam 4 refers to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com