Inverted drilling machine

An inverted drilling machine technology, applied to boring machine/drilling machine components, positioning devices, boring/drilling, etc., can solve the problems of unresolved accuracy, wear and tear of the end of the drill pipe, and reduce the processing accuracy Reduce, protect the drill pipe and workpiece, reduce the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

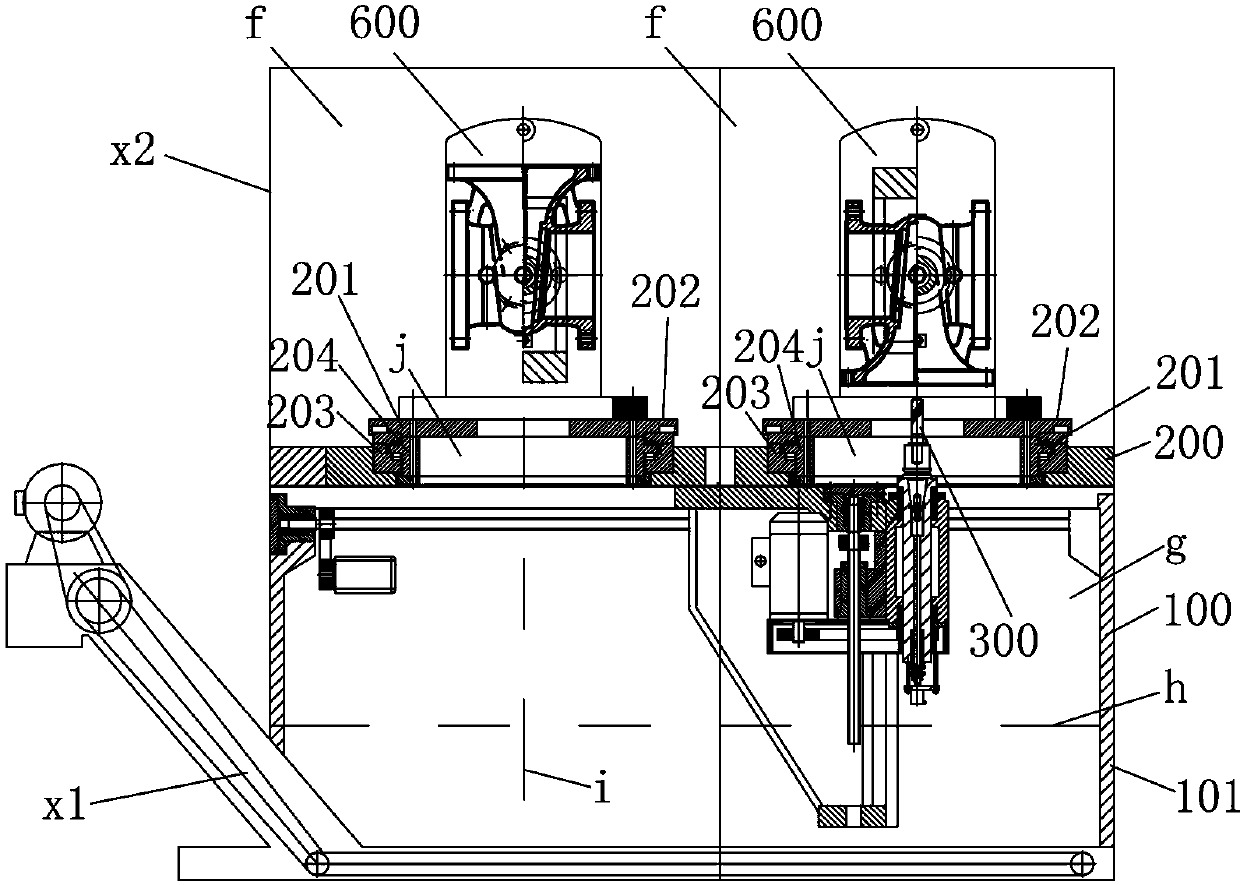

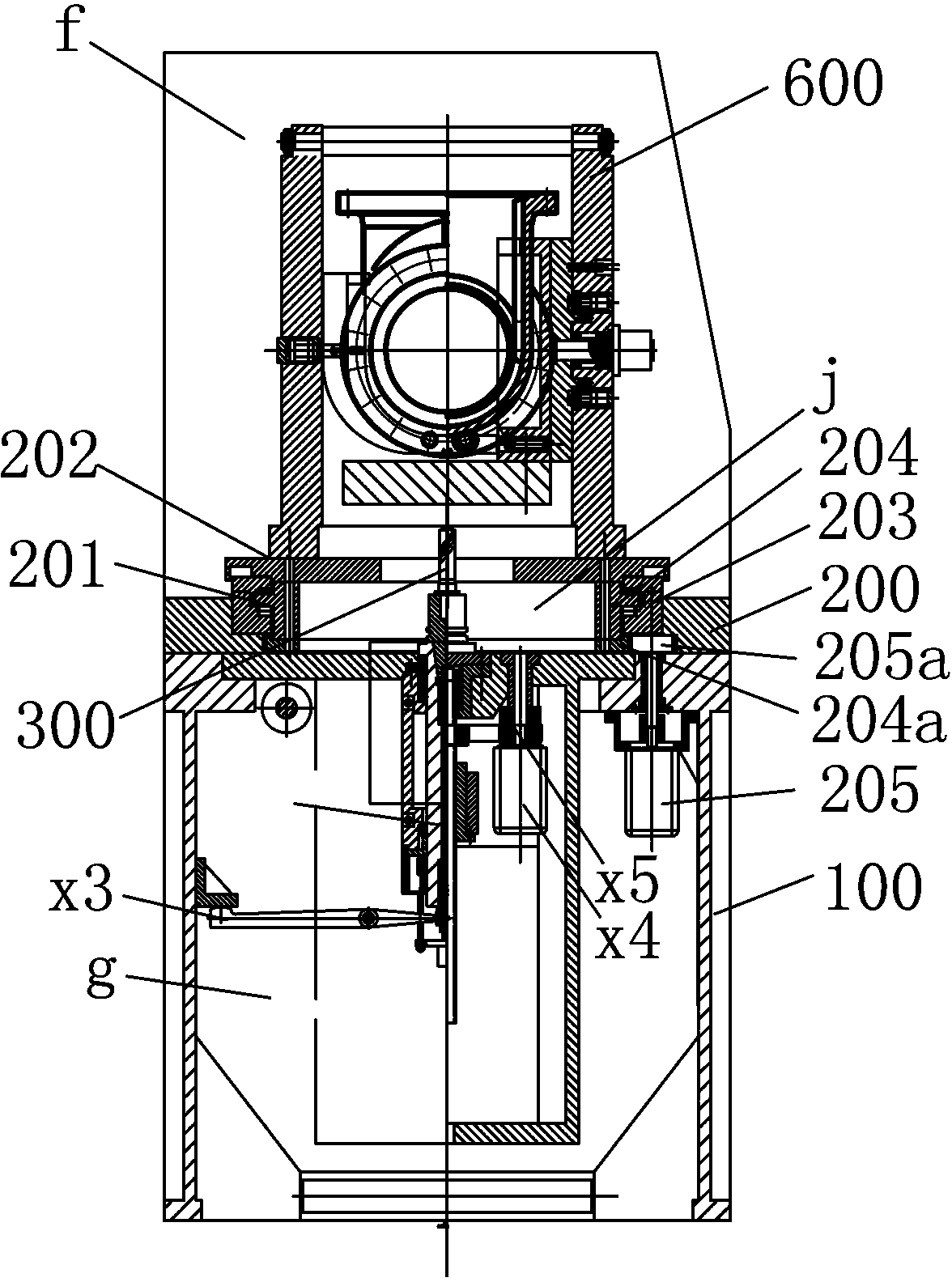

[0019] Figure 1 to Figure 2 Represents the overall structure of the embodiment of the inverted drilling machine of the present invention, including the bed 100 and the workbench 200, the workbench 200 is provided with a station part 201 and a drill part 300, and the drill part 300 is located below the station part 201, meaning The drill bit loaded on the drill part 300 will cut the workpiece from bottom to top, and the station part 201 is provided with a station 202 for loading the workpiece 9, a fixture part 600 for indexing processing of the workpiece 9 and a workpiece space above the station 202 f, the fixture part 600 is located in the workpiece space f, the workpiece 9 is loaded in the fixture part 600 , and the workpiece 9 and the fixture part 600 are loaded in the work station 202 as a whole.

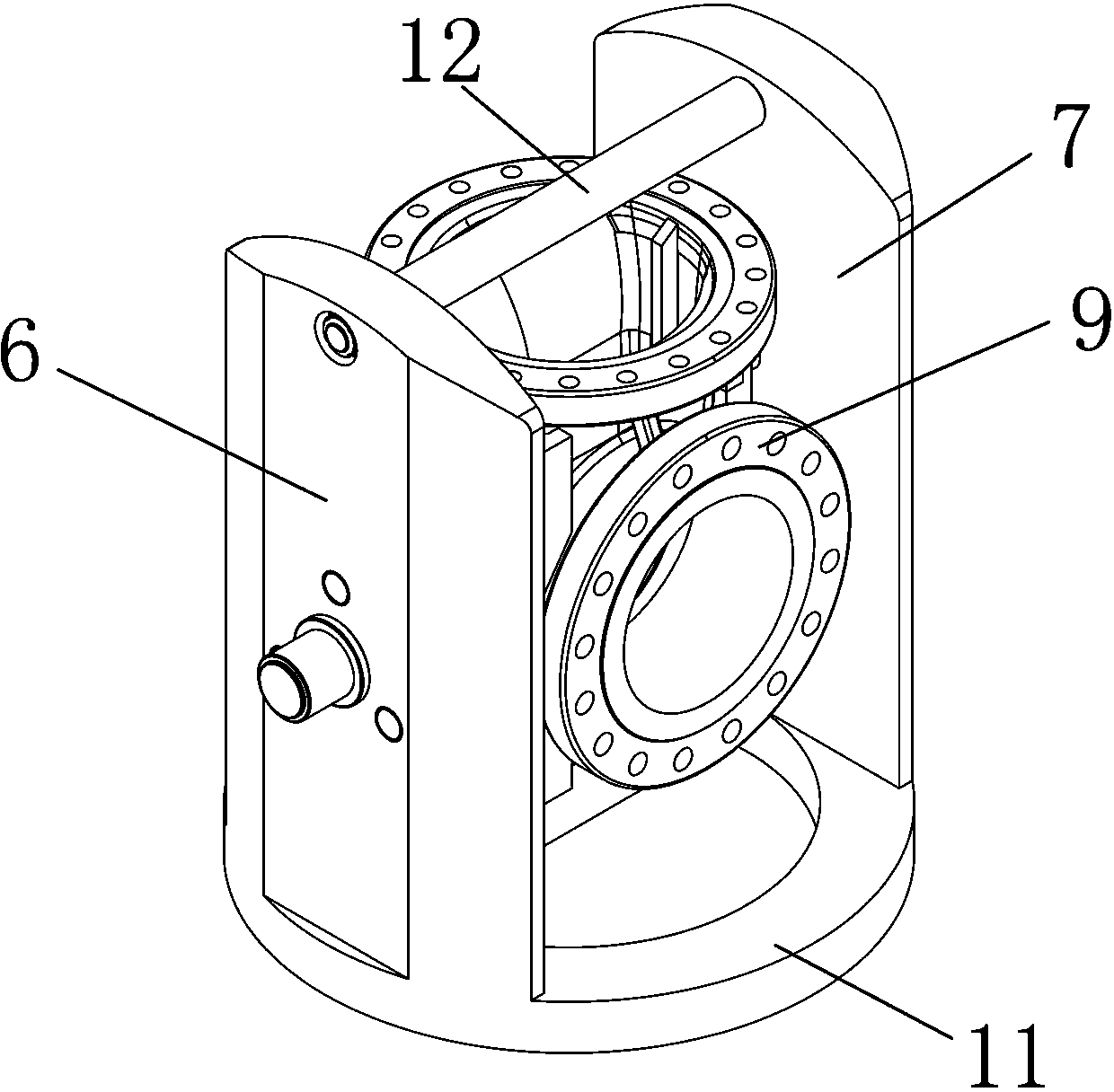

[0020] Figure 3 to Figure 7 The fixture part 600 in the embodiment is shown, and the fixture part 600 includes a fixture body space 8 for accommodating a workpiece 9, left and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com