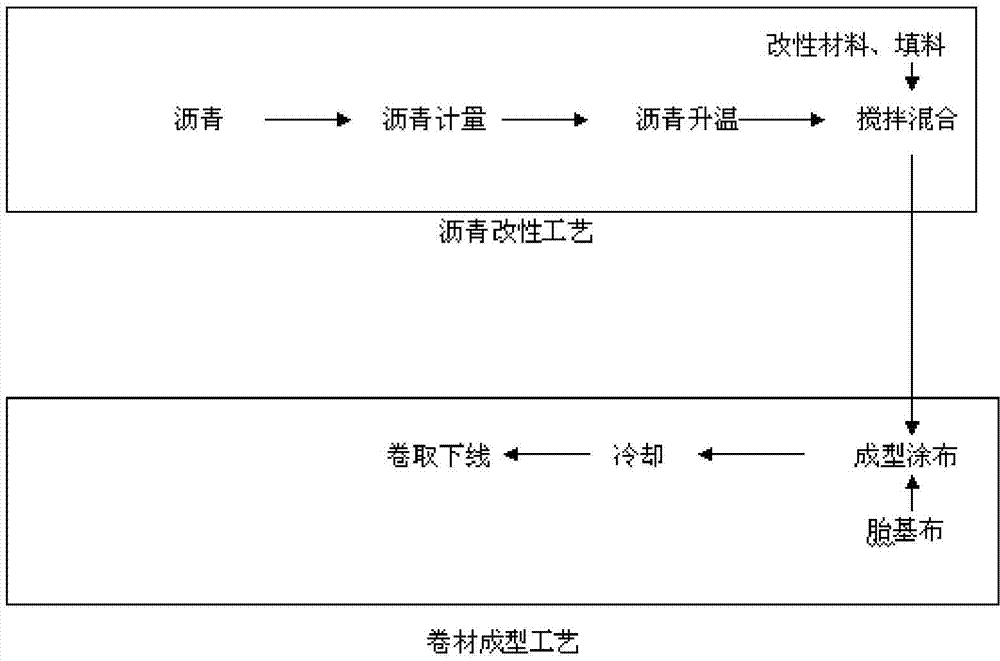

Material proportioning device for preparation of modified-asphalt waterproof coil material

A technology of waterproof membrane and modified asphalt, which is applied to mixers with rotating stirring devices, dissolving machines, mixers, etc., can solve problems such as difficulty in fully utilizing batching tanks, inability to achieve batching uniformity, waste of resources, etc., to achieve Reduce unevenness, simple structure, and ensure the quality of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

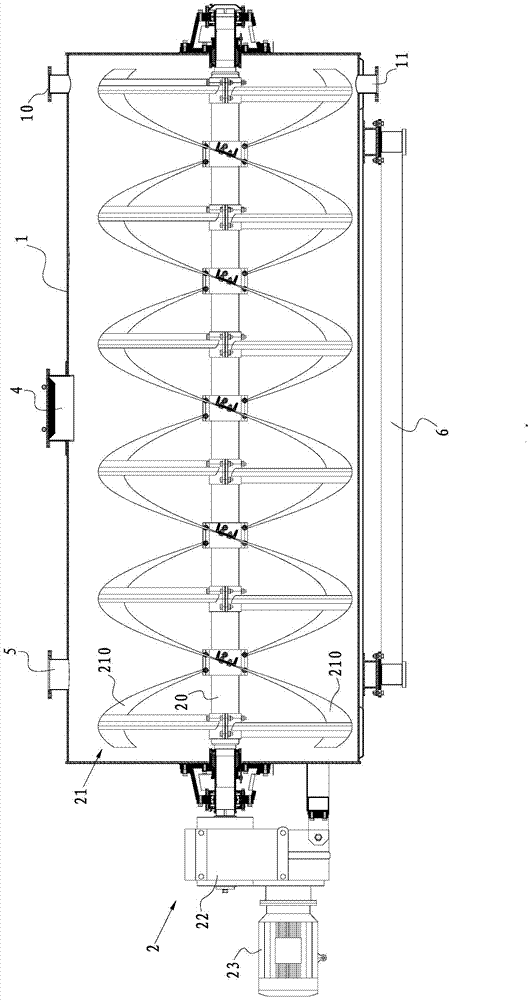

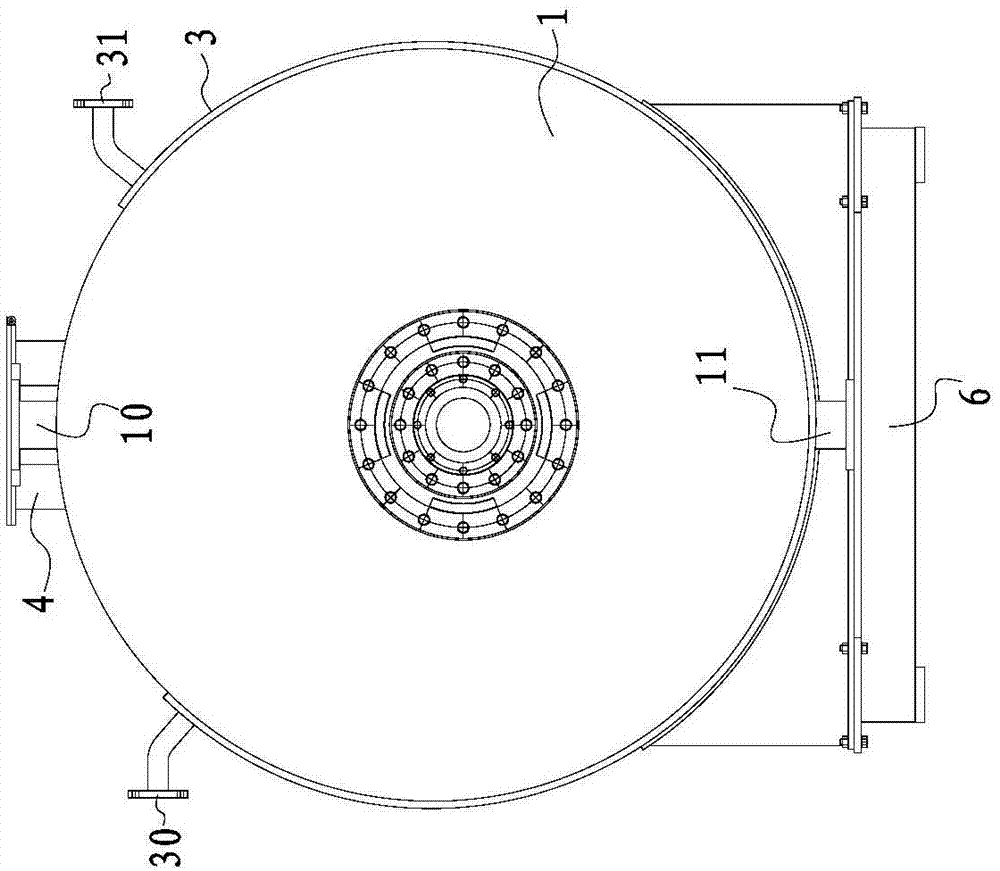

[0021] Such as figure 1 and figure 2 As shown, the batching device for preparing modified asphalt waterproof membrane according to this embodiment includes a batching tank 1 with a feed inlet 10 and a discharge outlet 11 , and a stirring device 2 . The stirring device 2 includes a driving motor 23 , a reducer 22 driven by the driving motor 23 , a stirring shaft 20 driven by the reducer 22 to rotate around its own axis, and a stirring paddle 21 arranged on the stirring shaft 20 .

[0022] In this example, the batching tank 1 is extended along the horizontal direction, and the stirring shaft 20 is arranged in the batching tank 1 along the extending direction of the batching tank 1. Helical ribbon 210 on agitator shaft 20 . Further, there are two helical ribbons 210, and the two helical ribbons 210 form a double helical ribbon stirring paddle (common knowledge in the art, not described in detail here, for details, see figure 1 shown).

[0023] In this example, a jacket 3 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com