Roller for mung bean huller capable of evenly stirring, shovelling and screening materials in real time

A peeling machine and drum technology, applied in the field of agricultural machinery, can solve the problems of reducing the rice yield and productivity, and the whole and half-grain mung beans cannot be discharged from the peeling drum in time, so as to improve the rice yield, improve the operation efficiency, and reduce excessive The effect of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

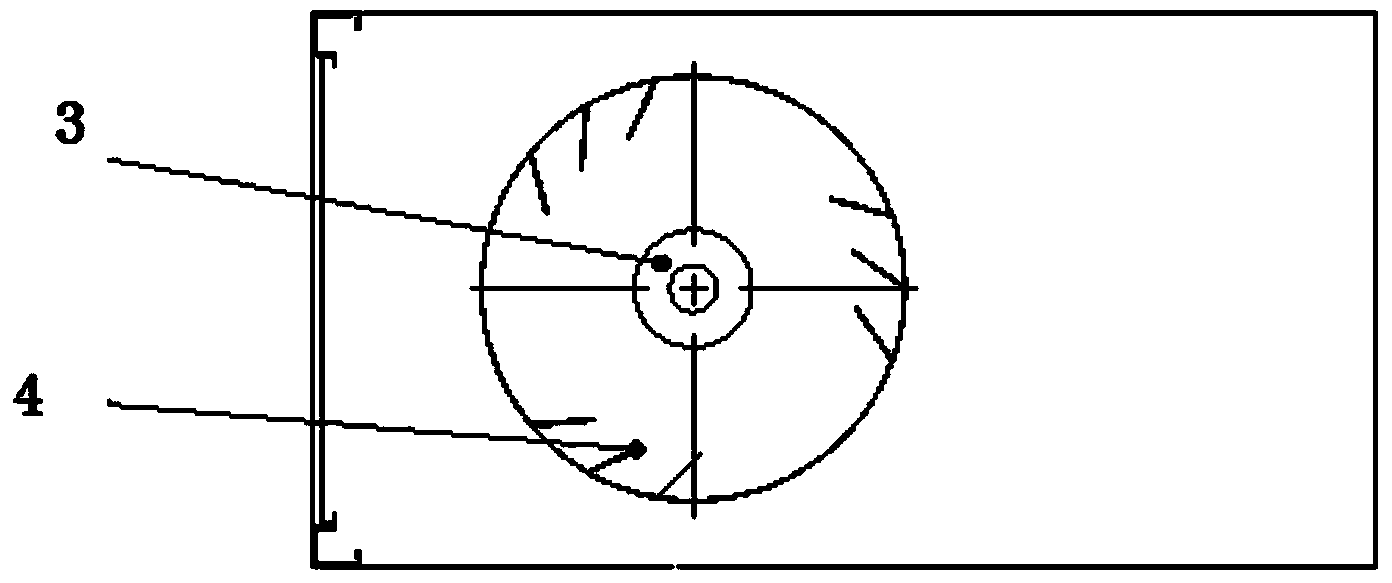

[0025] as attached Figure 1~4 As shown, a drum for mung bean peeling machine that can evenly sieve materials in real time includes one end mounted on the frame 1 bearing seat, and the other end mounted on the frame 1 mounting seat of the drum 2, the drum 2 It can rotate around its own axis, the surface is a mesh screen, the inner wall of the cylinder 2 protrudes from the lifting plate 4, and the axis of the cylinder 2 is equipped with a peeling grinding wheel 3, which is characterized in that:

[0026] The surface screen of the drum 2 is provided with oblong holes, the oblong mesh width a of the oblong holes is 1.8-2.4 mm, and the length b is 10-15 mm;

[0027] The lifting boards 4 on the inner wall of the drum 2 are divided into several groups at intervals along the circumferential direction, and each group is 3 sheets evenly distributed on the inner wall of the circumferential drum 2 .

[0028] The lifting boards 4 on the inner wall of the drum 2 are divided into three gro...

Embodiment 2

[0033] as attached Figure 5 As shown, on the surface screen of the drum 2 in the present invention, a round hole with a diameter greater than 3.2mm and less than 4mm is opened; the axial distance a' of the two adjacent rows of holes is 3-5mm, and the circumferential distance b' is 6 ~ 8mm.

[0034] The sieve holes of the drum of the present invention adopt the form of round holes or oblong holes, and the diameter is slightly smaller than the minimum width of the fully peeled half-grain mung beans, which is convenient for sorting the complete peeled whole-grain and half-grain mung beans. The built-in lifting boards are evenly distributed on the circumference of the drum, which can turn and mix the materials during the operation process. There is a gap between each group of lifting boards, which is conducive to the relative displacement between the material and the drum, making it easier for small-sized materials to be sorted. The whole device not only ensures the rice output ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com