Agricultural unmanned cultivator

An unmanned, tiller technology, applied in the field of tillers, can solve the problems of poor sustainable production capacity, environmental factors, high use requirements, and small scope of use, so as to enhance sustainable production capacity and reduce use requirements. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

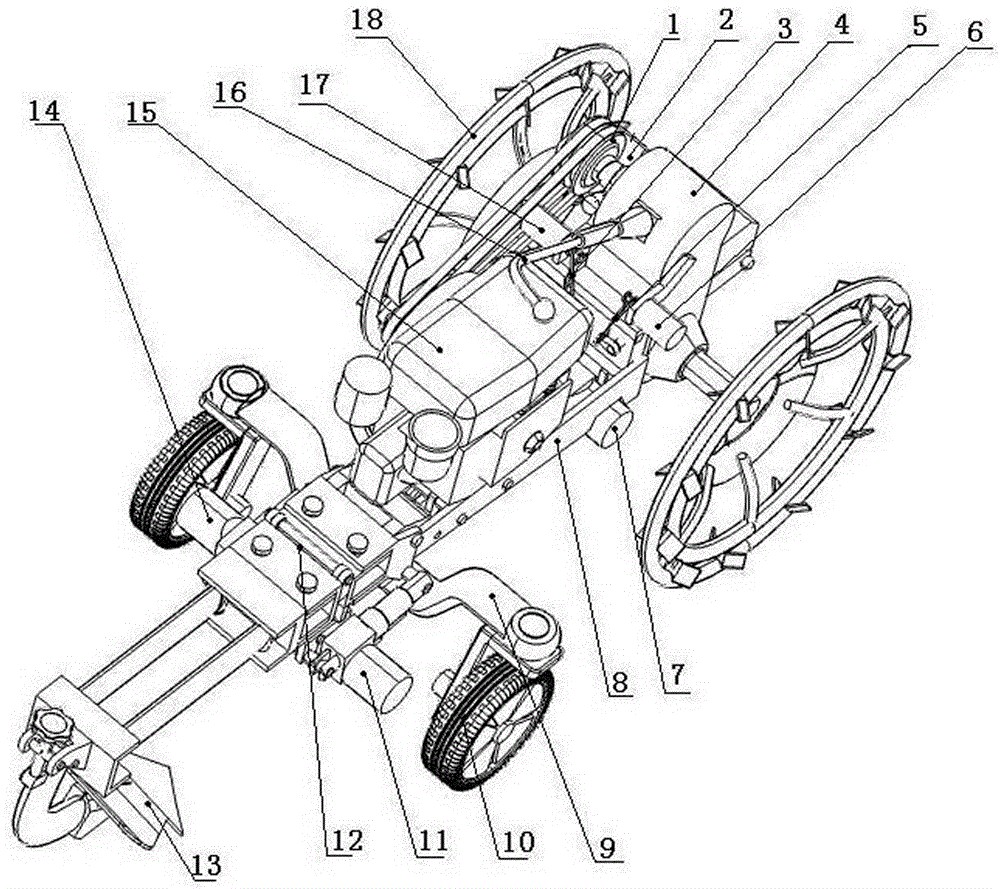

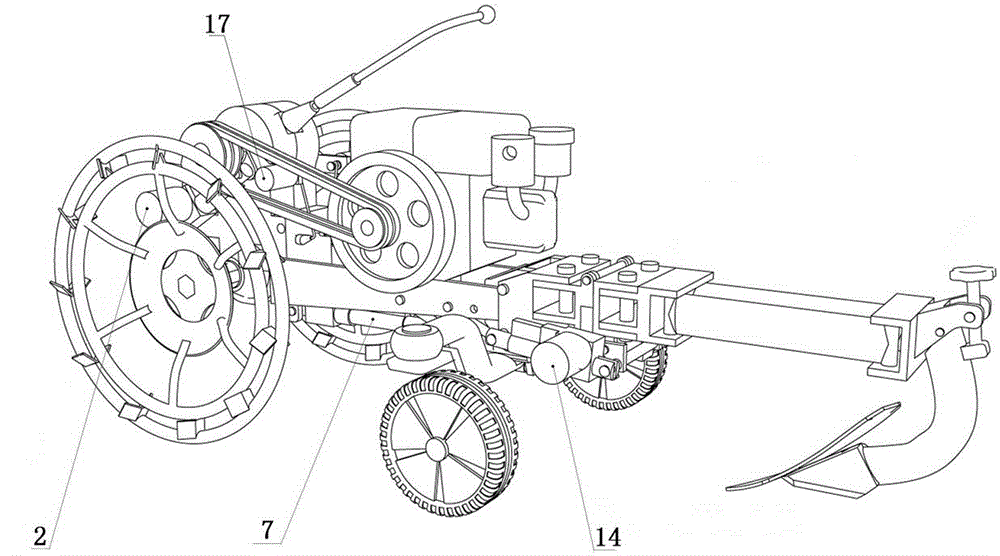

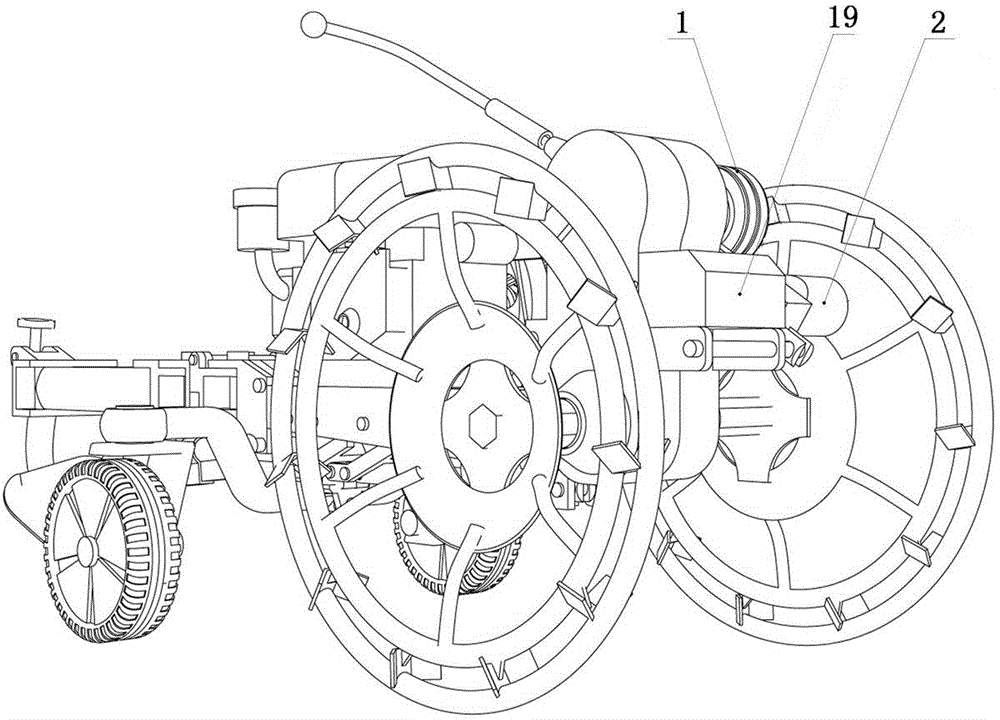

[0029] Embodiment 1: An agricultural unmanned cultivator adopts a four-wheel structure, the front wheels are two driving wheels 18, and the rear wheels are two guide wheels 10, such as Figure 1-1 to Figure 1-3 As shown, it includes gearbox 4, rear guide mechanism, chassis 8, four-bar mechanism 20, clutch 1, left brake control lever 26, right brake control lever 27, accelerator control lever 25, tillage assembly 13, lifting self-locking Mechanism 12, electric push rod Ⅰ7, electric push rod Ⅱ2, electric push rod Ⅲ11, electric push rod Ⅳ14, steering gear 23, deceleration motor Ⅰ17 and deceleration motor Ⅱ6. The universal wheel 10 connected with the cross arm of the guide wheel is formed, and the tillage assembly is a plow or a harrow or other agricultural implements such as a seed spreader, an irrigation hose and the like.

[0030] The electric push rod I7 is connected with the guide wheel cross arm 9 of the rear guide mechanism through the four-bar mechanism 20 (see Figure 2-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com