Mechanical tripping mechanism for earth leakage protection socket

A technology of leakage protection and tripping mechanism, applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of button misoperation, button wear, and low service life, and achieve the effects of timely tripping, rapid action and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

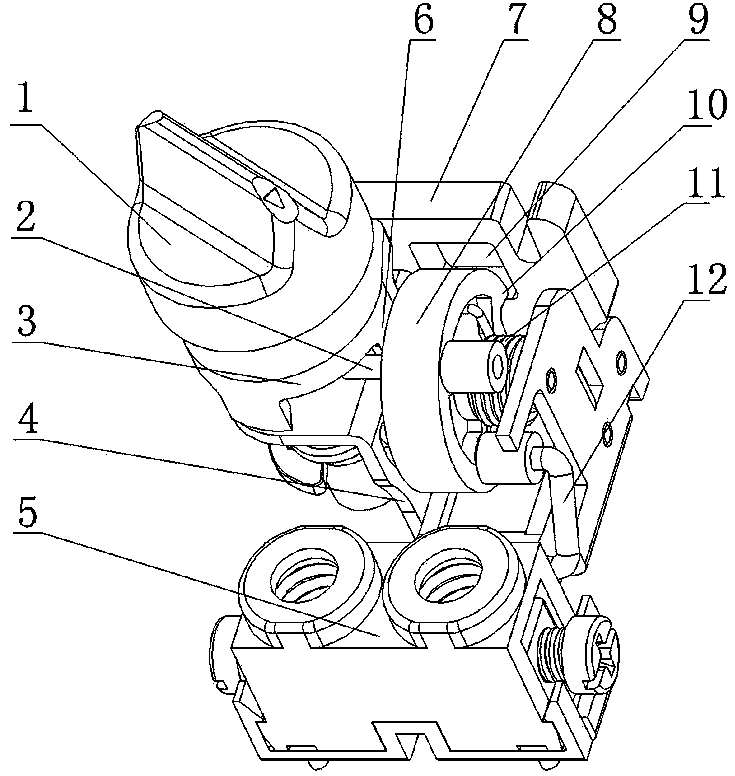

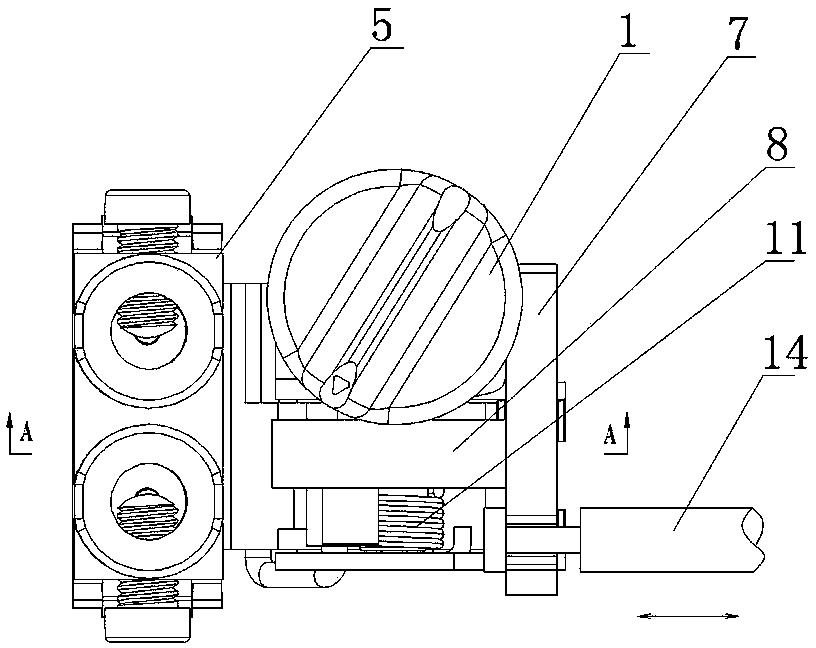

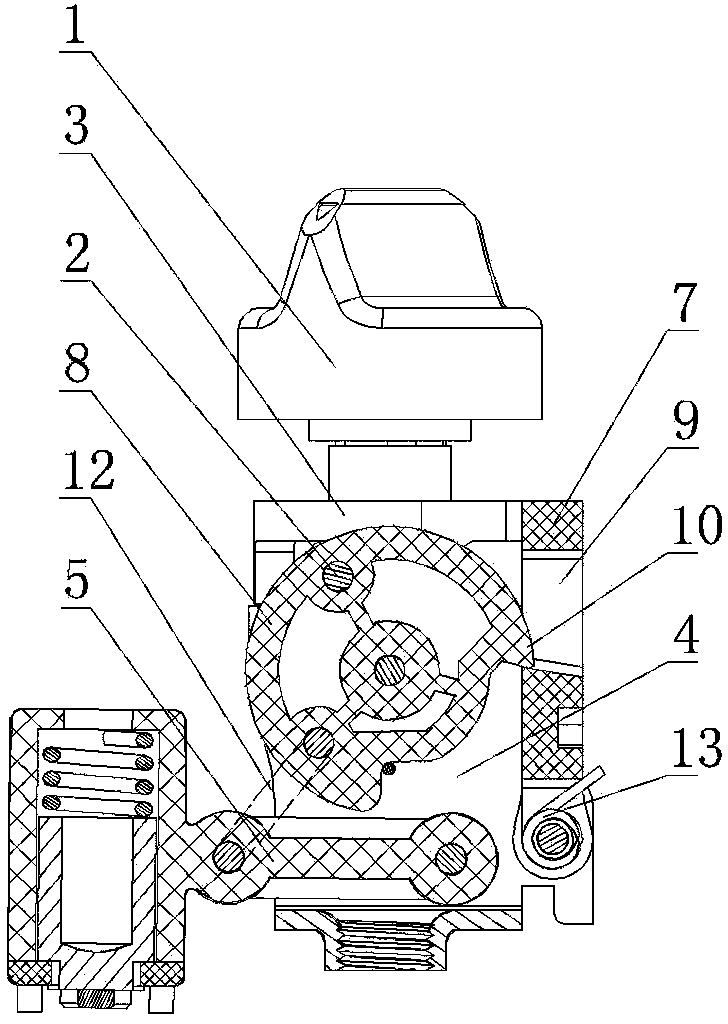

[0014] refer to figure 1 , figure 2 , image 3 As shown, this mechanical tripping mechanism for leakage protection sockets includes a bracket 4, a tripping cam 3, a tripping plate 7, a rotating wheel 8 and a wiring seesaw 5, and the tripping cam 3 is rotatably arranged on On the top of the bracket 4, the tripping cam 3 is connected to the knob 1. The tripping plate 7 is arranged to swing left and right on one side of the tripping cam 3 and is reset by the first torsion spring 13. Next, the swing end of the trip plate 7 is against the cam surface of the trip cam 3, the rotating wheel 8 is rotatably arranged inside the bracket 4 and reset by the second torsion spring 11, the rotating wheel 8 is provided with a locking The convex edge 10 and the trip plate 7 are provided with a locking window 9. When the mechanical tripping mechanism is in the state before tripping, the locking convex edge 10 hooks the locking window 9, and the connecting seesaw 5 is on the rotating wheel. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com