Quick acquisition method of true stress strain curve in whole process of uniaxial drawing

A technology of uniaxial tension and strain curve, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of unsuitable engineering stress-strain curve and parts deformation difference, and achieve the effect of easy operation and weakening influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

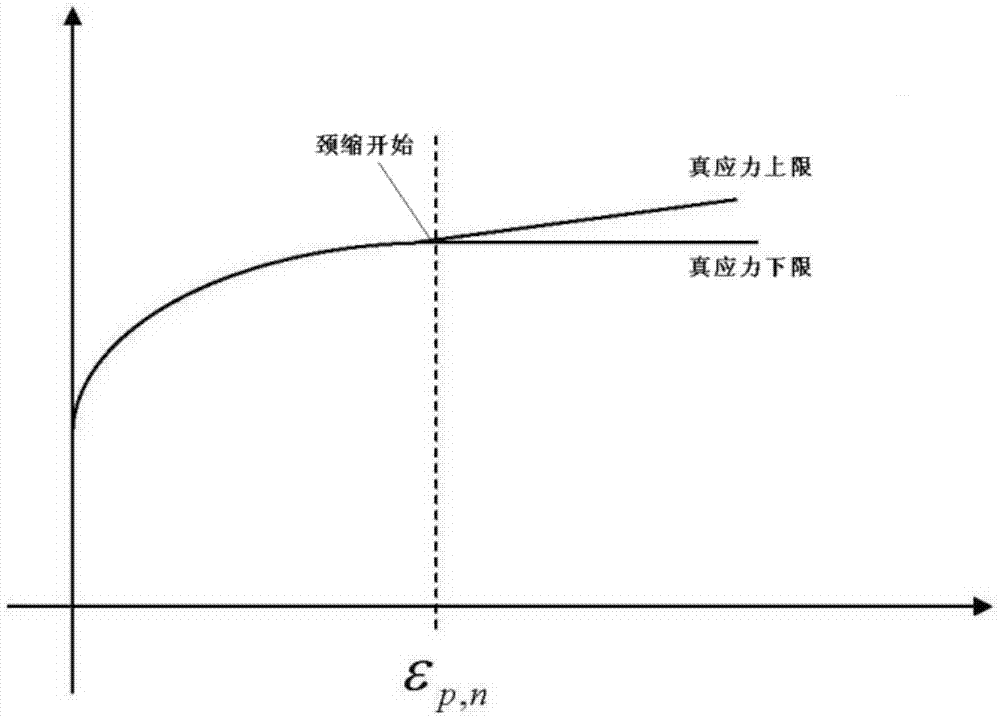

[0041] 1. According to the uniaxial tensile national standard GB / T228, the load-displacement curve of the sample is measured by loading the extensometer, and the original size of the sample is measured to calculate the engineering stress-engineering strain curve. The elastic modulus is calculated by using the elastic deformation stage curve; in the uniform plastic deformation stage, the true stress-true strain curve is obtained by using formula (1) and formula (2).

[0042]2. Remove the elastic deformation stage from the obtained true stress-true strain curve in the uniform plastic deformation stage to obtain the plasticity curve of the material. For materials with a yield platform, the starting position of the plastic curve is selected from the starting position of the yield platform; for the curve without a yield platform, the starting position of the plastic curve is determined according to the engineering residual strain of 0.2%, and the corresponding true strain and true s...

Embodiment 2

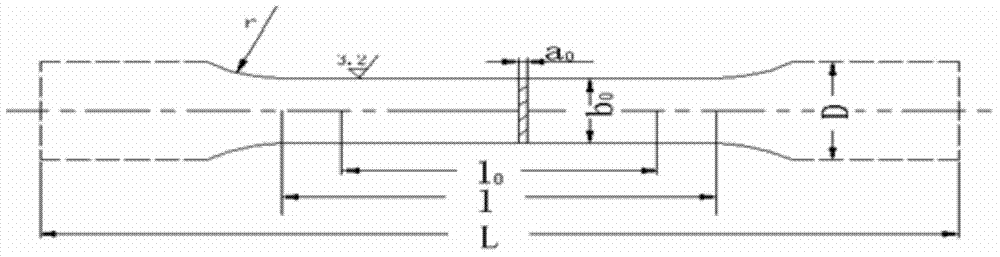

[0048] Take a steel plate commonly used in automobiles (choose 2.0 thickness, see the shape of the sample figure 2 , sample size see Table 1) as an example

[0049] Table 1 Dimensions of uniaxial tension sample

[0050] Sample name

a 0

b 0

D

l 0

l

L

r

50 gauge length

plate thickness

25

30

50

75

≥180

25~40

[0051] The implementation method of indirectly obtaining the equivalent true stress-true strain curve of the whole stretching process through the combination of test and CAE is as follows.

[0052] 1. According to the metal material uniaxial tensile test standard GB / T228, the initial length of the extensometer is selected as 80mm, and the load-displacement curve of the sample is measured ( image 3 ). By measuring the original cross-sectional area of the test, the engineering stress-engineering strain curve ( Figure 4 ).

[0053] 2. Use the elastic deformation stage curve to calculate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com