Method for realizing wide nano-particle beams by using neutral cluster beam nozzle assembly

A nanoparticle and beam technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as diminishing returns, and achieve the effect of increasing utilization and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

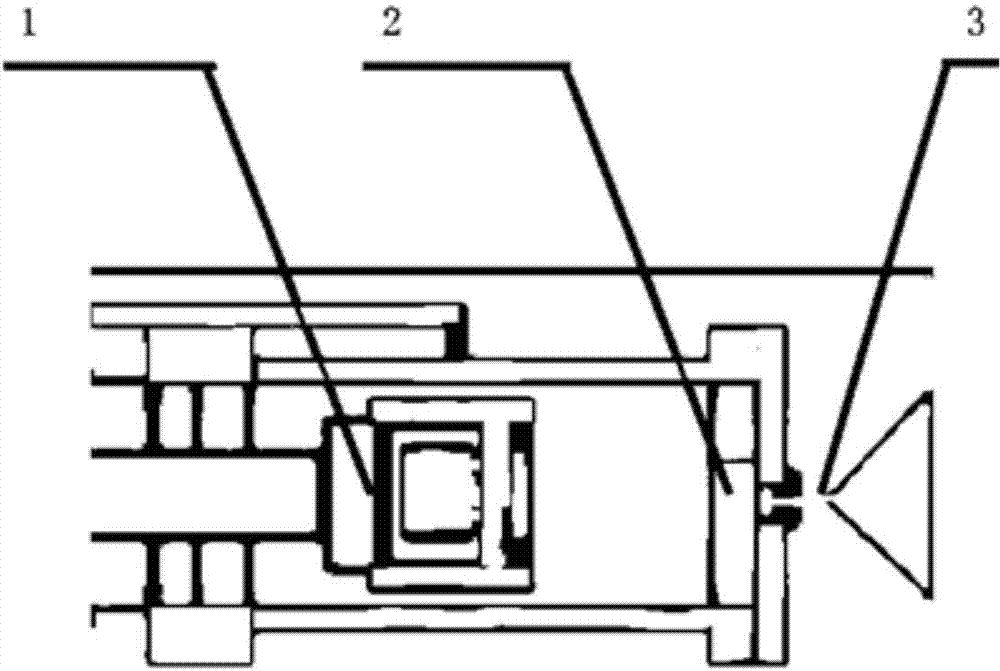

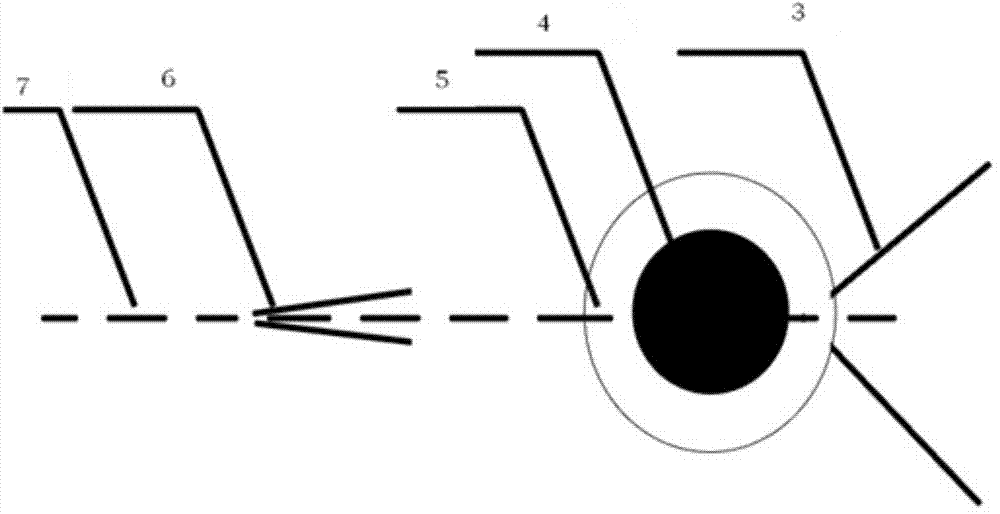

[0032] Figure 1-4 As shown in , sputtering target 1, nozzle hole 2, separation hole (separator) 3, beam center 4, beam outer edge 5, nozzle hole 6, and beam axis 7.

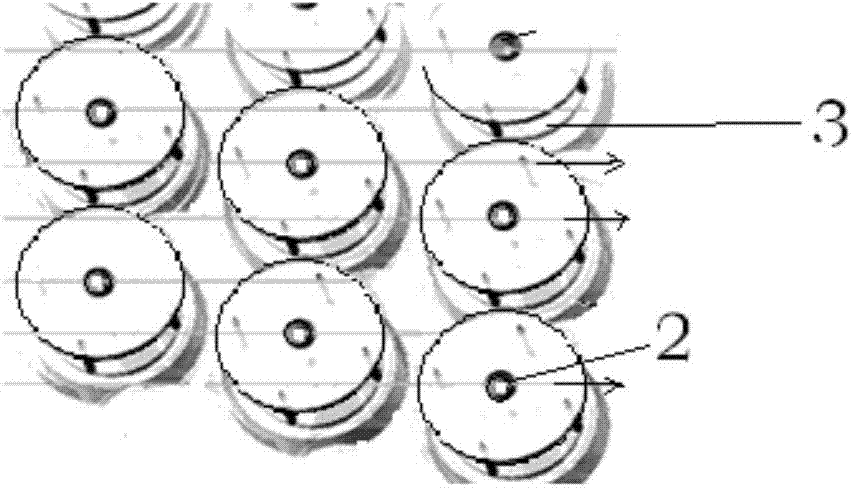

[0033] Equally scaled down, cluster beam guns with smaller diameters are used, and multiple beam guns are integrated together using a beam cluster plate. Such as image 3 , the beam cluster plate is divided into two layers, the first layer is a plurality of (beam gun) nozzles, the second layer is a separator, and the separator corresponds to the nozzle one by one (to form a beam gun), the separator It is on a straight line with the axis of the nozzle, and the distance between the two layers is between 0.5cm and 5cm.

[0034] Furthermore, this cluster beam gun can be used to form a continuous wide-width nanoparticle beam. The key point is to integrate enough beam guns and scan the substrate to be processed in a given direction. In particular, at this time, the number of cluster beam guns integrated in the beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com