A kind of roller coating type imitation brick coating

A technology of simulation and facing bricks, applied in the direction of coating, etc., can solve the problems of increased anti-pollution performance, achieve the effects of saving materials, improving the utilization rate of paint materials, reducing loss and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

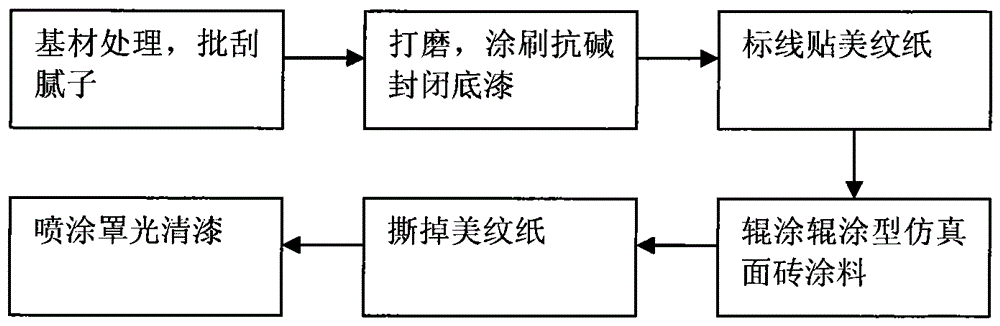

Method used

Image

Examples

Embodiment 1

[0038] 150 parts by weight of water, 20 parts by weight of ethylene glycol, 3 parts by weight of dispersant, 1 part by weight of AMP95, 50 parts by weight of 2% hydroxyethyl cellulose solution, 30 parts by weight of 10% inorganic gel, 1 part by weight of wetting agent Add the parts by weight into the dispersing kettle to disperse evenly, and then add 2 parts by weight of defoamer to adjust the speed to 800-1200r / min and disperse for 20 minutes. Sequentially add 4 parts by weight of defoamer, 50 parts by weight of elastic polymer emulsion, 100 parts by weight of rigid polymer emulsion, and 10 parts by weight of film-forming aid and stir for 5 minutes, then add hydrophobically modified alkali-swellable thickening thickener 9 Parts by weight, 2 parts by weight of hydrophobically modified alkali-swellable associative thickener, 1.5 parts by weight of bactericide, and 20 parts by weight of water are dispersed for 30 minutes to obtain the finished roller coating type imitation brick ...

Embodiment 2

[0040] 135 parts by weight of water, 10 parts by weight of ethylene glycol, 4 parts by weight of dispersant, 1.5 parts by weight of AMP95, 75 parts by weight of 2% hydroxyethyl cellulose solution, 30 parts by weight of 10% inorganic gel, 1.5 parts by weight of wetting agent Add parts by weight into the dispersing kettle to disperse evenly, then add 3 parts by weight of defoamer to adjust the speed to 800-1200r / min and disperse for 20 minutes, after adjusting the speed to 600r / min, add 550 parts by weight of colored sand mineral powder and disperse for 3 minutes, Sequentially add 4 parts by weight of defoamer, 75 parts by weight of elastic polymer emulsion, 75 parts by weight of rigid polymer emulsion, and 7 parts by weight of film-forming aid and stir for 5 minutes, then add 7 parts by weight of hydrophobically modified alkali-swellable thickening type thickener Parts by weight, 3 parts by weight of hydrophobically modified alkali-swellable associative thickener, 1.5 parts by w...

Embodiment 3

[0042]120 parts by weight of water, 10 parts by weight of ethylene glycol, 3 parts by weight of dispersant, 2 parts by weight of AMP95, 50 parts by weight of 2% hydroxyethyl cellulose solution, 30 parts by weight of 10% inorganic gel, and 2 parts by weight of wetting agent Add the parts by weight into the dispersing kettle to disperse evenly, and then add 3 parts by weight of defoamer to adjust the speed to 800-1200r / min and disperse for 20 minutes. After adjusting the speed to 600r / min, add 600 parts by weight of colored sand mineral powder and disperse for 3 minutes. Sequentially add 4 parts by weight of defoamer, 100 parts by weight of elastic polymer emulsion, 50 parts by weight of rigid polymer emulsion, 5 parts by weight of film-forming aid and stir for 5 minutes, then add hydrophobically modified alkali-swellable thickening type thickener 5 Parts by weight, 5 parts by weight of hydrophobically modified alkali-swellable associative thickener, 1.5 parts by weight of bacter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com