Preparation method of lycium barbarum polysaccharide

A technology of Lycium barbarum polysaccharide and Lycium barbarum, which is applied in the field of biological extraction and separation, can solve the problems of polysaccharide degradation, polysaccharide biological activity destruction, short extraction time, long time consumption, etc., and achieves the effects of improving extraction rate, short extraction time and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

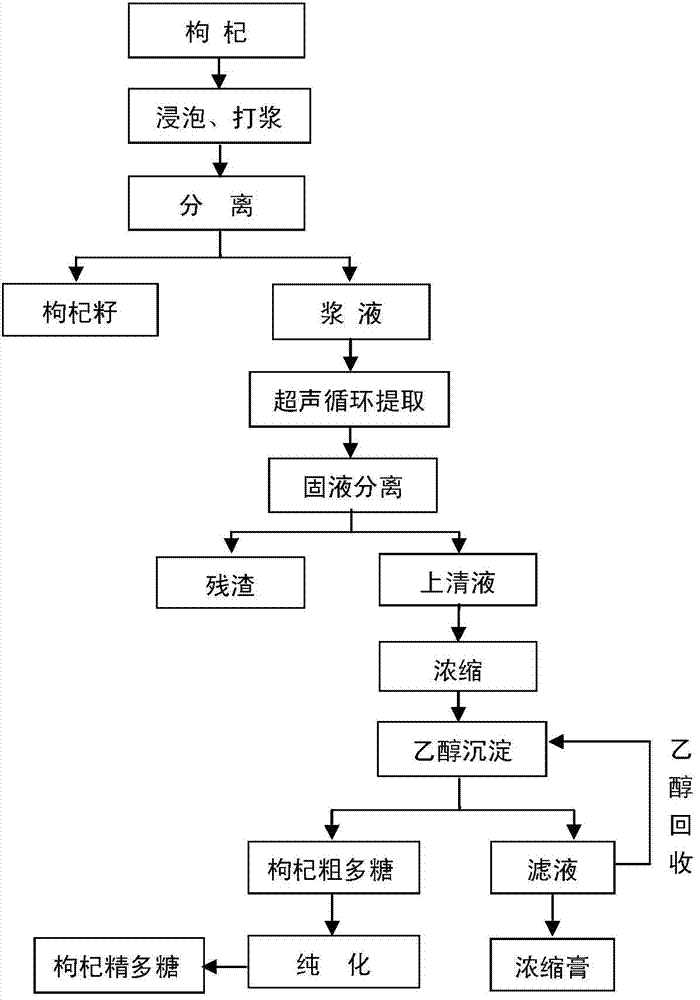

[0034] Embodiment 1 A kind of preparation method of Lycium barbarum polysaccharide

[0035] (1) Soak the wolfberry with water (1:10), beat the pulp, and separate the pulp from the wolfberry seeds. You can use stirring to naturally settle the wolfberry seeds, or use an automatic seed removal machine to remove the wolfberry seeds;

[0036] (2) Lycium barbarum pulp was extracted in a circulating ultrasonic extraction machine; the extraction conditions were: temperature 40°C, ultrasonic power 500W, circulation speed 2000rpm; duty ratio 1:3, ultrasonic extraction time 2h.

[0037] (3) After the extraction is completed, the solid and liquid are separated, and the supernatant is concentrated under vacuum and reduced pressure;

[0038] (4) After concentrating to 1 / 10 of the volume of the original extract, add ethanol until the concentration of ethanol is 75% for static precipitation to obtain the crude polysaccharide precipitate of Lycium barbarum.

[0039] (5) Dry the crude polysacc...

Embodiment 2

[0040] Embodiment 2 A kind of preparation method of Lycium barbarum polysaccharide

[0041] (1) Soak wolfberry with water (material-to-liquid ratio 1:8), beat, stir and suspend the pulp, and then let it stand for 10 minutes to allow the wolfberry seeds to settle naturally, thereby separating the wolfberry seeds;

[0042] (2) Put wolfberry pulp in a circulating ultrasonic extraction machine for extraction. The conditions of circulating ultrasonic extraction are: temperature 30°C, ultrasonic power 1200W, cycle speed 1000rpm, duty ratio 1:2, ultrasonic extraction time 1h.

[0043] (3) After the extraction is completed, the solid and liquid are separated, and the supernatant is concentrated by vacuum decompression, and the concentration ratio is 1 / 5 of the volume of the extract.

[0044] (4) After concentrating the extract, add ethanol until the concentration of ethanol is 85%, and let it stand for precipitation to obtain crude polysaccharide precipitate of Lycium barbarum.

[00...

Embodiment 3

[0054] Embodiment 3 A kind of preparation method of Lycium barbarum polysaccharide

[0055] (1) Soak wolfberry with water (material-to-liquid ratio: 1:20), make a pulp, and use an automatic seed separator to separate the seeds of wolfberry.

[0056] (2) Lycium barbarum pulp was extracted in a circulating ultrasonic extraction machine; the conditions of circulating ultrasonic extraction were: temperature 30°C, ultrasonic power 800W, cycle speed 1500rpm, duty ratio 1:2, ultrasonic extraction time 1.5h.

[0057] (3) After the extraction is completed, the solid and liquid are separated, and the supernatant is concentrated by vacuum concentration under reduced pressure;

[0058] (4) After the extract was concentrated, ethanol was added to a final concentration of 80% for static precipitation to obtain crude polysaccharide precipitates from Lycium barbarum.

[0059] (5) The crude polysaccharide precipitate is dried by spray drying. The spray drying conditions are: the air inlet tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com