Method for catalyzed synthesis of quinoxaline compounds by yb/nay molecular sieve catalyst

A molecular sieve and catalyst technology, which is applied in the field of Yb/NaY molecular sieve catalyst to catalyze the synthesis of quinoxaline compounds, can solve problems such as higher requirements for synthesis conditions, and achieve the effects of simple synthesis method, high loading rate and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Synthesis of Yb / NaY Molecular Sieve Catalyst

[0037] (1) Put the NaY molecular sieve powder in a polytetrafluoroethylene liner, add distilled water and magnets for electromagnetic stirring, and add dry YbCl while stirring 3 Powder, NaY and YbCl 3 The mass ratio is 1:1;

[0038] (2) Take out the magnet after stirring for 0.5h, wash it with distilled water, close the hydrothermal reaction kettle, and the filling degree of the polytetrafluoroethylene liner is 70%;

[0039] (3) Put the reactor into an oven, heat up to 180°C, take it out after 1 hour, and cool it with tap water;

[0040] (4) The mixture is centrifuged, and the liquid is evaporated to dryness to obtain incompletely reacted YbCl 3 , recovery, the solid is a loaded molecular sieve, and dried;

[0041] (5) Transfer the dried Yb / NaY molecular sieve to a crucible, heat up to 550°C in a muffle furnace at 10°C / min and then calcinate for 5h to obtain a Yb / NaY molecular sieve catalyst;

[0042] (6) Carry out ICP...

Embodiment 2

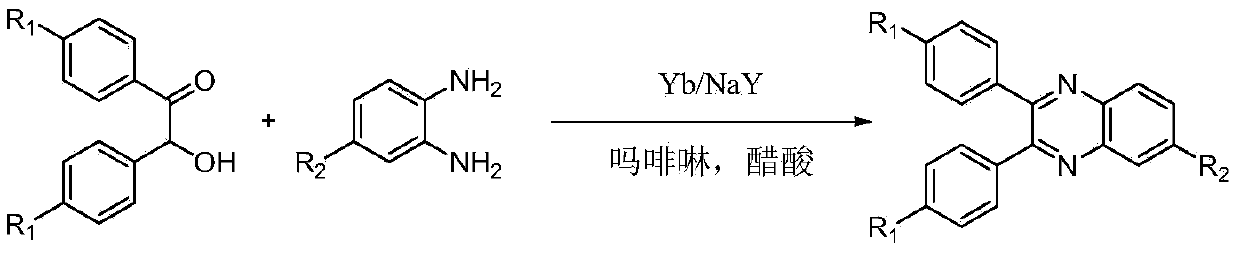

[0044] The Yb / NaY molecular sieve catalyst prepared in Example 1 was used to catalyze the synthesis of quinoxaline compounds from α-hydroxyketone and o-phenylenediamine.

[0045] 1mmol benzoin, 2mmol o-phenylenediamine, 0.35mmol morpholine and 0.05mmol Yb 3+ Place the Yb / NaY molecular sieve catalyst in a 25mL round-bottomed flask, add 5mL of acetic acid and a magneton, stir and reflux at 80°C for 4h. The obtained mixture is filtered, and the filter residue is a Yb / NaY molecular sieve catalyst, reclaimed, and the filtrate is separated by column chromatography to obtain a pure product, and the product structural formula is

[0046]

[0047] The yield was 93%, and the Yb / NaY molecular sieve catalyst was recovered and reused four times, and the yields were 91%, 93%, 92%, and 93%, respectively.

Embodiment 3

[0049]The Yb / NaY molecular sieve catalyst prepared in Example 1 was used to catalyze the synthesis of quinoxaline compounds from α-hydroxyketone and o-phenylenediamine.

[0050] 1 mmol 2-hydroxy-1,2-di-p-tolylethanolone, 2 mmol o-phenylenediamine, 0.35 mmol morpholine and 0.05 mmol Yb 3+ Place the Yb / NaY molecular sieve catalyst in a 25mL round-bottomed flask, add 5mL of acetic acid and a magneton, stir and reflux at 80°C for 4h. The obtained mixture is filtered, and the filter residue is a Yb / NaY molecular sieve catalyst, reclaimed, and the filtrate is separated by column chromatography to obtain a pure product, and the product structural formula is:

[0051]

[0052] The yield is 94%, and the Yb / NaY molecular sieve catalyst is recovered and reused once, and the yield is 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com