Preparation of Heteroatom Ligand of Sulfur and Nitrogen and Its Application

A technology of sulfur nitrogen heteroatoms, which is applied in the preparation of sulfur nitrogen heteroatom ligands and the application field of the ligands, can solve problems such as bad odor, and achieve the effect of reducing the use and simplifying the synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

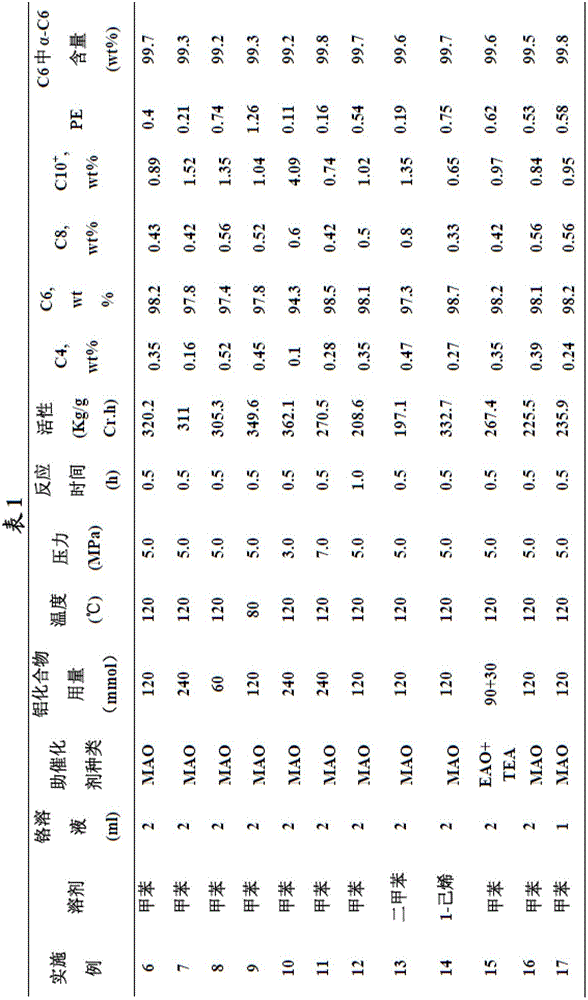

Examples

Embodiment 1

[0038] The preparation of embodiment 1 sulfur nitrogen heteroatom ligand

[0039] Preparation of (di-(2-ethylthio-ethyl)-amine)

[0040] At -15°C, dissolve 8.0g (100mmol) of sodium hydroxide solution and 12.46g (100mmol) of 2-chloroethyl ethyl sulfide in 200ml of ethanol, and then add 2mol / LNH 3 25ml of methanol solution was added thereto. The solution was stirred at -15°C for 2 hours and then at room temperature for 15 hours. After the reaction was completed, filter, evaporate the filtrate to dryness, and add the residue to 50ml of diethyl ether to filter again and evaporate to dryness. After repeated several times, a light yellow oily product was obtained with a yield of 8.85g (92%). 1 H-NMR (CDCl 3 ): δ1.20 (6H, t, CH 3 ), 2.50 (1H, s, NH), 2.57 (4H, q, SCH 2 CH 3 ), 2.70 (4H,t,Sch 2 ), 2.83 (4H, t, NCH 2 ).

Embodiment 2

[0041] The preparation of the chromium complex of embodiment 2 sulfur nitrogen heteroatom ligand

[0042] Preparation of chromium trichloride (di-(2-ethylthio-ethyl)-amine)

[0043] At room temperature, a solution of 3.18 g (16.5 mmol) of di-(2-ethylthio-ethyl)-amine prepared in Example 1 in 50 ml THF was added to a solution containing 5.62 g (15 mmol) of CrCl 3 (THF) 3 150ml THF solution. After stirring was continued for 30 minutes, the solvent was removed in vacuo until a residue of 30 ml remained. Another 80 mL of ether was added, the solution was filtered and the solids were washed. A first wash with a mixture of ether and THF (100ml each) followed by a 50ml ether wash. The solid was dried under vacuum. Yield: 3.88 g (76.8%).

[0044] The elemental analysis instrument was CE-440 produced by Jialian Instrument Co., Ltd. of the United States.

[0045] The atomic absorption instrument is AA-400 produced by PerkinElmer, USA.

[0046] Elemental analysis of the product: ...

Embodiment 3

[0049] The preparation of embodiment 3 sulfur nitrogen heteroatom ligands

[0050] Preparation of (di-(2-phenylthio-ethyl)-amine)

[0051] At -5°C, dissolve 8.0g of sodium hydroxide and 17.26g (100mmol) of 2-chloroethylbenzene sulfide in 200ml of ethanol, and then add 2mol / LNH 3 25ml of methanol solution was added thereto. The solution was stirred at -5°C for 3 hours, then at room temperature for 20 hours. After filtering, the filtrate was evaporated to dryness, and the residue was added to 60ml of diethyl ether to filter again and evaporate to dryness. After repeated several times, 18.5g of bis(2-phenylthio-ethyl)-amine (yield: 64% ). 1H-NMR (CDCl 3 ): 2.05 (1H, s, NH), 7.28 (8H, d, CH), 7.24 (2H, d, CH), 2.89 (8H, t, CH 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com