Sound insulation composite wall and floor board

A composite wall and floor technology, applied in the field of sound insulation materials, can solve the problems of hard sound insulation effect, unsatisfactory hollow drum sound, etc.

Active Publication Date: 2014-05-14

深圳市爱思宝科技发展有限公司

View PDF2 Cites 43 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the sound insulation material is an assembled material, which is easy to form a sound bridge, and the sound insulation effect is not ideal if the material is hard, and the hollow sound is loud

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

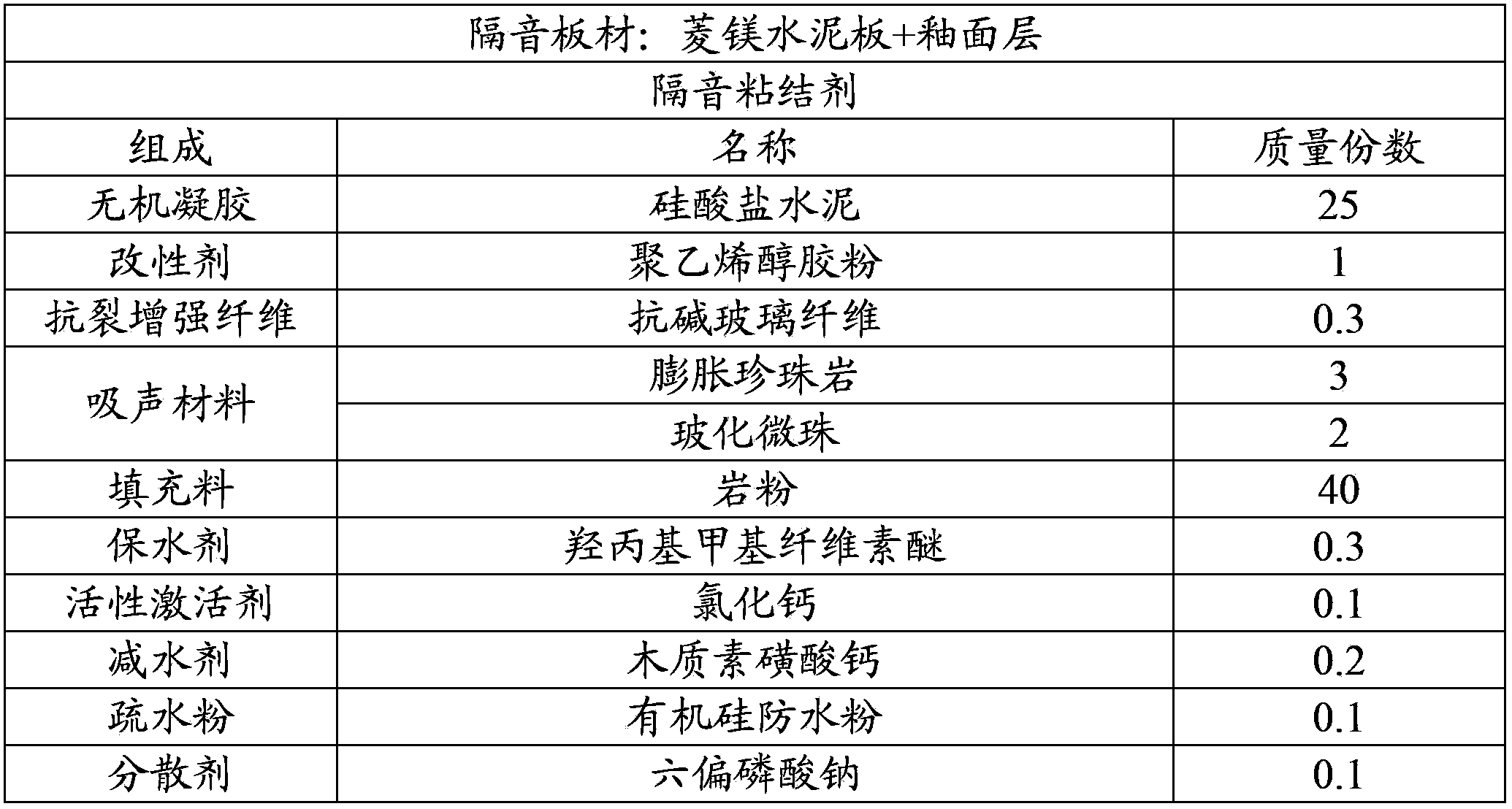

Embodiment 1

[0062]

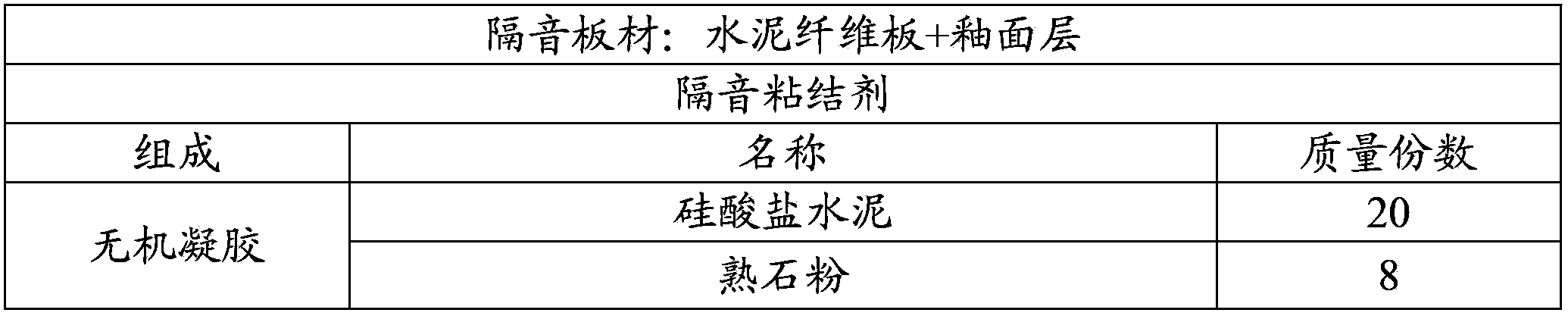

Embodiment 2

[0064]

[0065]

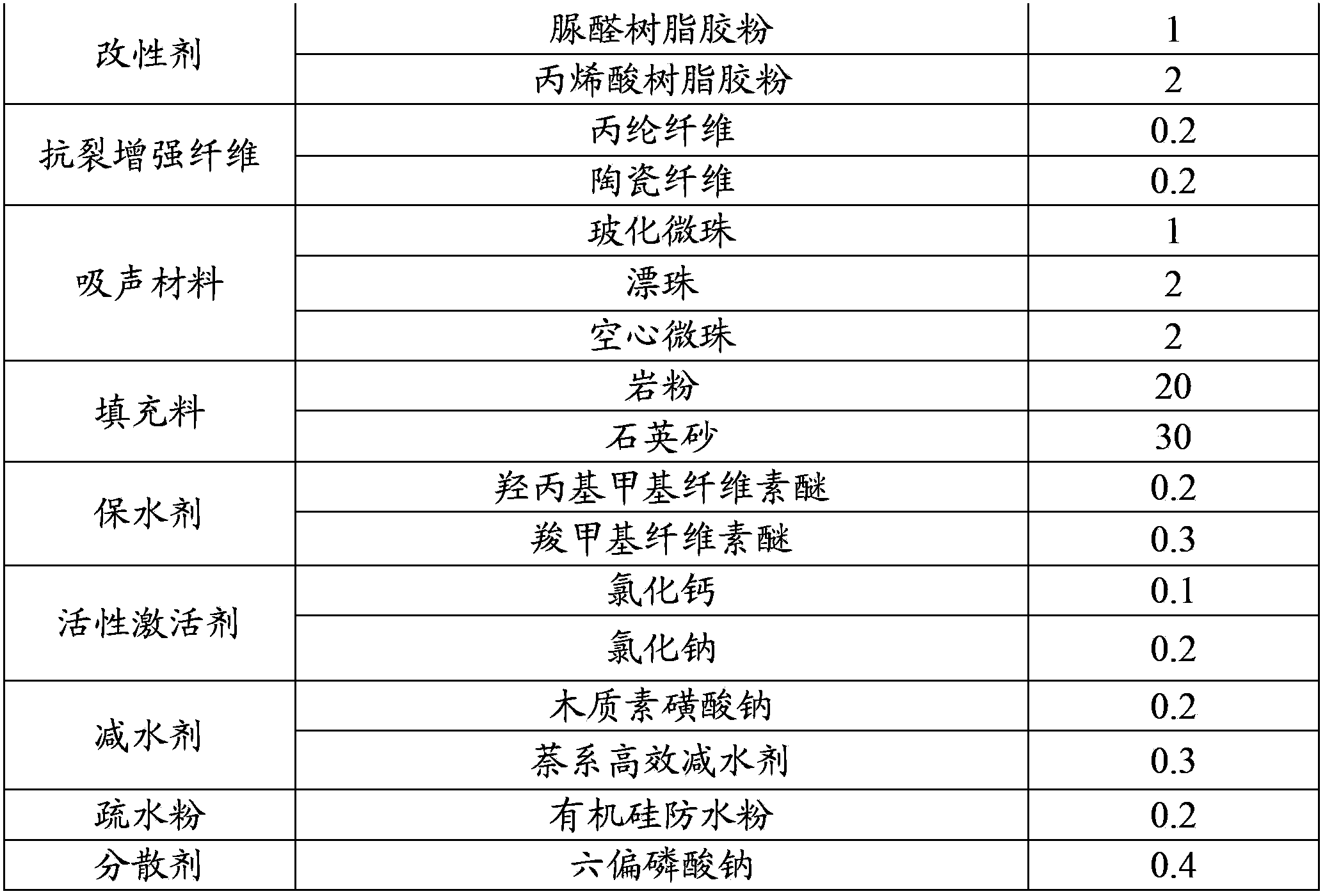

Embodiment 3

[0067]

[0068]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A sound insulation composite a wall and floor board, including a sound insulation sheet material and a sound insulation binder for adhering the sound insulation sheet material to the wall and floor of the building. The sound insulation sheet material comprises a substrate and a glaze layer adhered on the substrate, the sound insulation binder includes, by mass fraction, 25-30 parts of an inorganic gel, 1-5 parts of a modifier, 0.3-0.5 part of anti-cracking reinforced fiber, 5-8 parts of a sound absorbing material, 40-60 parts of a filler, 0.3-0.6 part of a water retaining agent, 0.1-0.5 part of an activation activating agent, 0.2-0.8 part of a superplasticizer, 0.1-0.3 part of a hydrophobic powder and 0.1-0.6 part of a dispersant. The sound insulation sheet material contains a large amount of interconnected micro voids, and sound waves can penetrate deep inside the material along these pores and generates friction effect with the material, so that the acoustic energy is converted into heat energy. In addition, the sound insulation binder contains the sound-absorbing material consisting of an unconsolidated porous material, which has gradually increased sound absorption coefficient from low frequency to high frequency, so that the sound insulation binder has good sound absorption effect on high-frequency and intermediate-frequency sound.

Description

technical field [0001] The invention relates to sound-insulating materials, in particular to a sound-insulating composite wall and floor. Background technique [0002] At present, most of the floor slabs are made of reinforced concrete, and the sound insulation effect is relatively poor. The traditional sound insulation method is to lay glass wool or linoleum cloth, but the sound insulation and vibration damping board using glass wool is not accepted by the market because the glass wool is not pressure-resistant and the vibration damping effect is weak; It is not environmentally friendly and toxic, and the prepared product has poor sound insulation effect, cannot be recognized by the market, and is difficult to promote. With the continuous improvement of people's living standards, the requirements for living comfort are getting higher and higher, and it is bound to put forward higher requirements for the sound insulation performance of the floor to meet the privacy and comf...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/04C04B28/10C04B28/14

Inventor 郑述

Owner 深圳市爱思宝科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com