An Integrated Multichannel Energy Harvesting Micromechanical Structure

A technology of micro-mechanical structure and energy harvesting, applied in micro-structure technology, micro-structure device, micro-structure device composed of deformable elements, etc., to achieve the effect of high survival coefficient, low production cost, simple principle and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

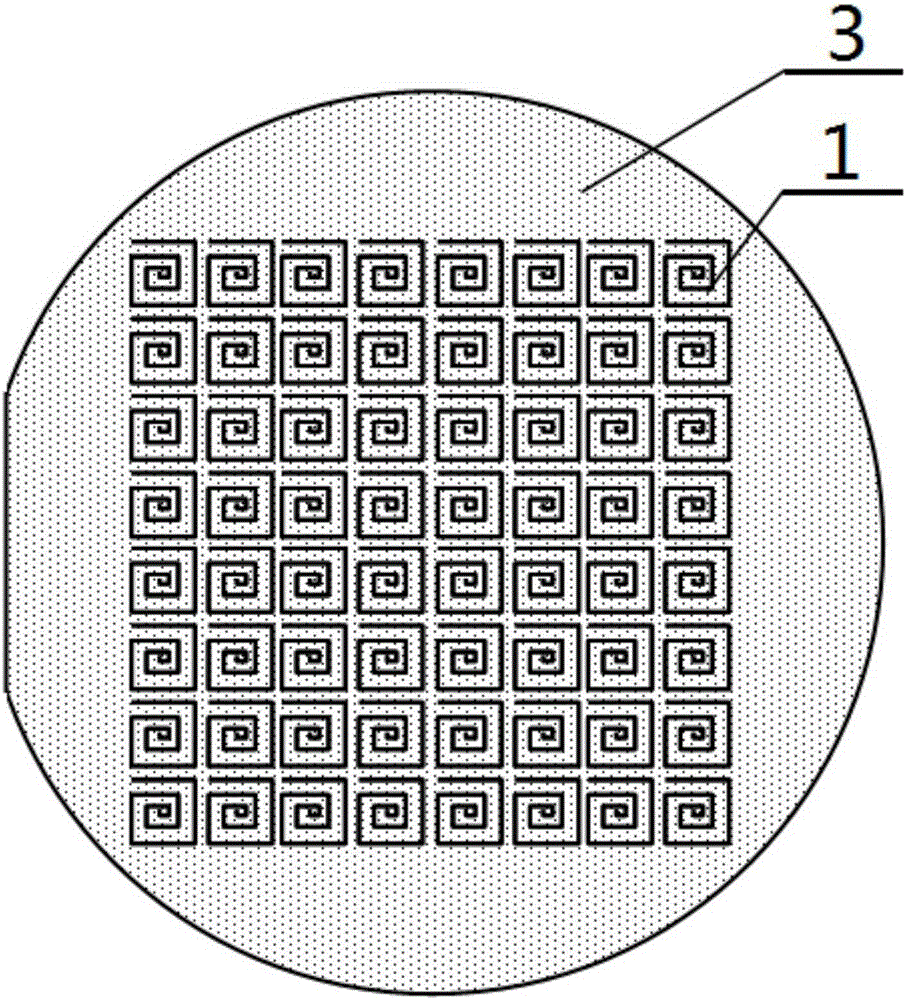

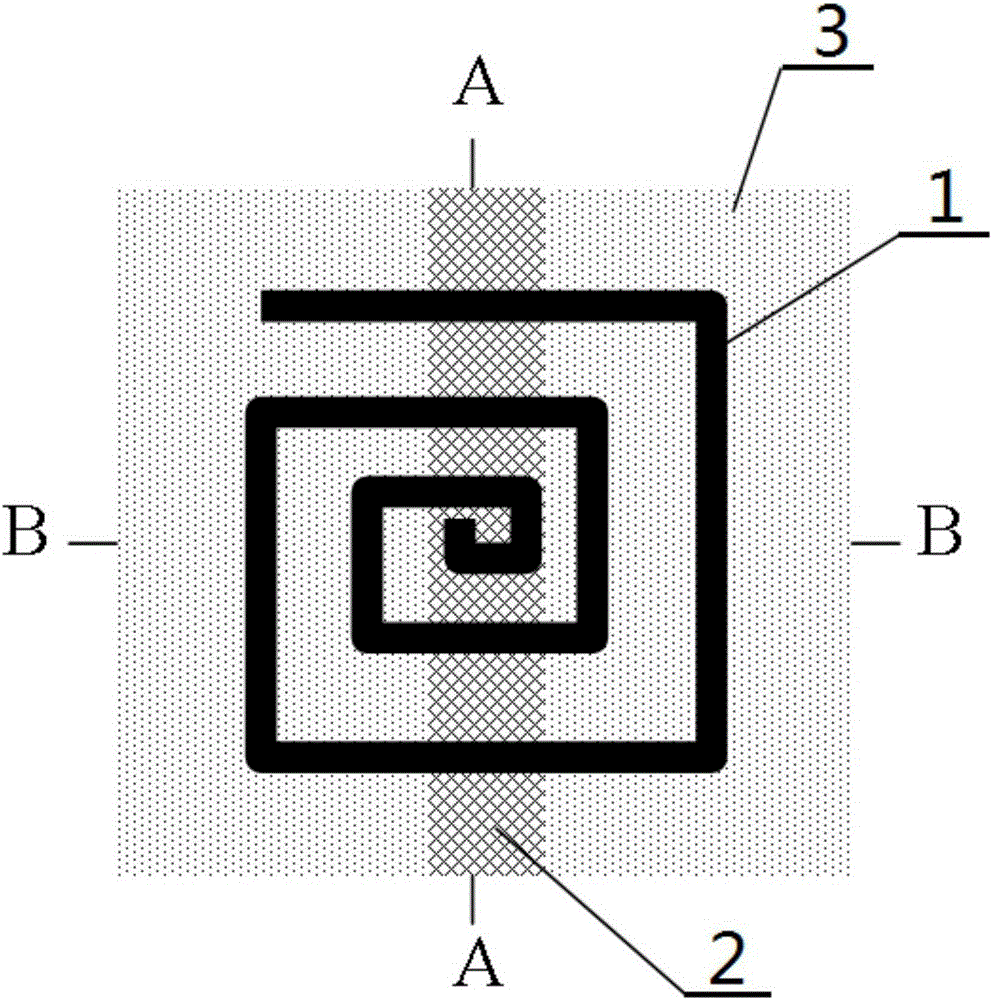

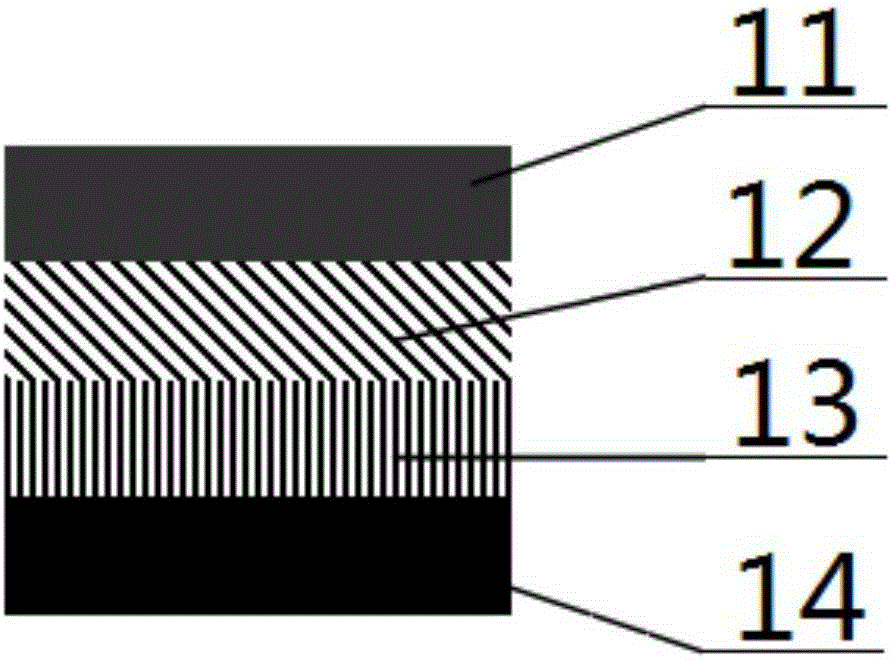

[0025] Such as Figure 1 to Figure 5 Shown is an integrated multi-channel energy harvesting micromechanical structure, including a wafer substrate 4 and an energy harvesting unit 1; a lower electrode 3 is grown on the upper surface of the wafer substrate 4; the energy harvesting unit 1 It is a planar structure composed of multi-layer thin films, including a first insulating dielectric layer 14, an electret thin film layer 13, a second insulating dielectric layer 12 and a conductive electrode layer 11 from bottom to top. The energy collection unit 1 passes through the column 2 It is fixed above the wafer substrate 4 and forms a cantilever beam structure. In the natural state, the energy harvesting unit 1 is parallel to the position of the lower electrode 3; the conductive electrode layer 11 provides a low-loss carrier path for electromagnetic wave energy absorption, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com