Centrifugal type non-contact wetting device of offset machine

An offset printing and centrifugal technology, applied in printing presses, rotary printing presses, offset rotary printing presses, etc., can solve the problems of contamination of fountain solution, changes in adjustment amount, and impact on printing quality, and achieves improved printing quality and precise control. effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

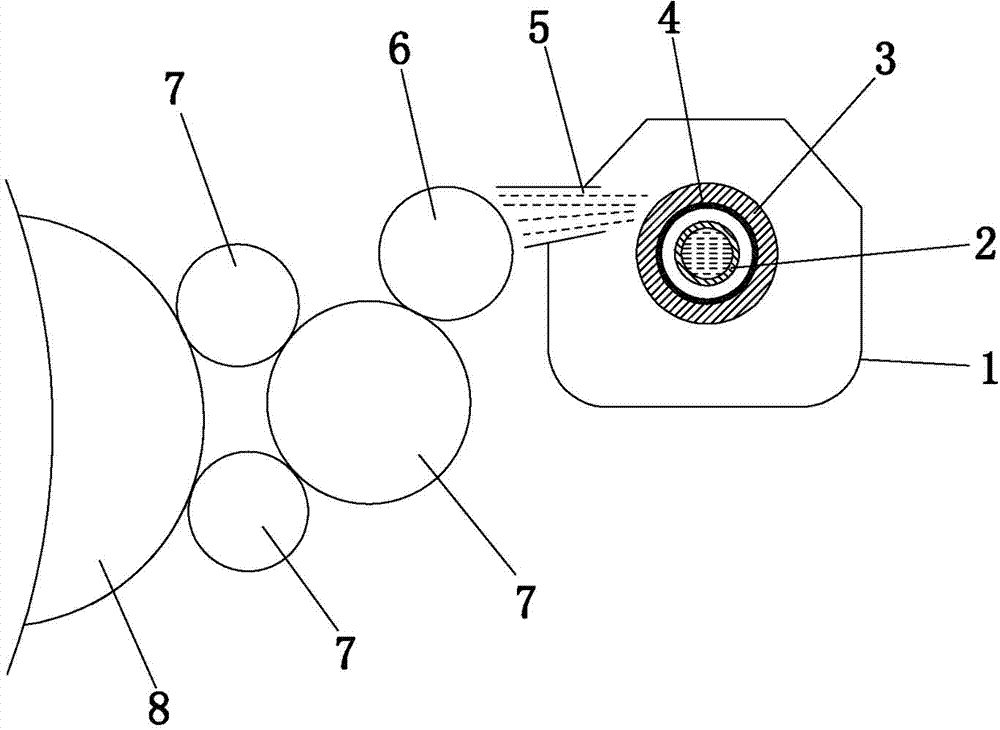

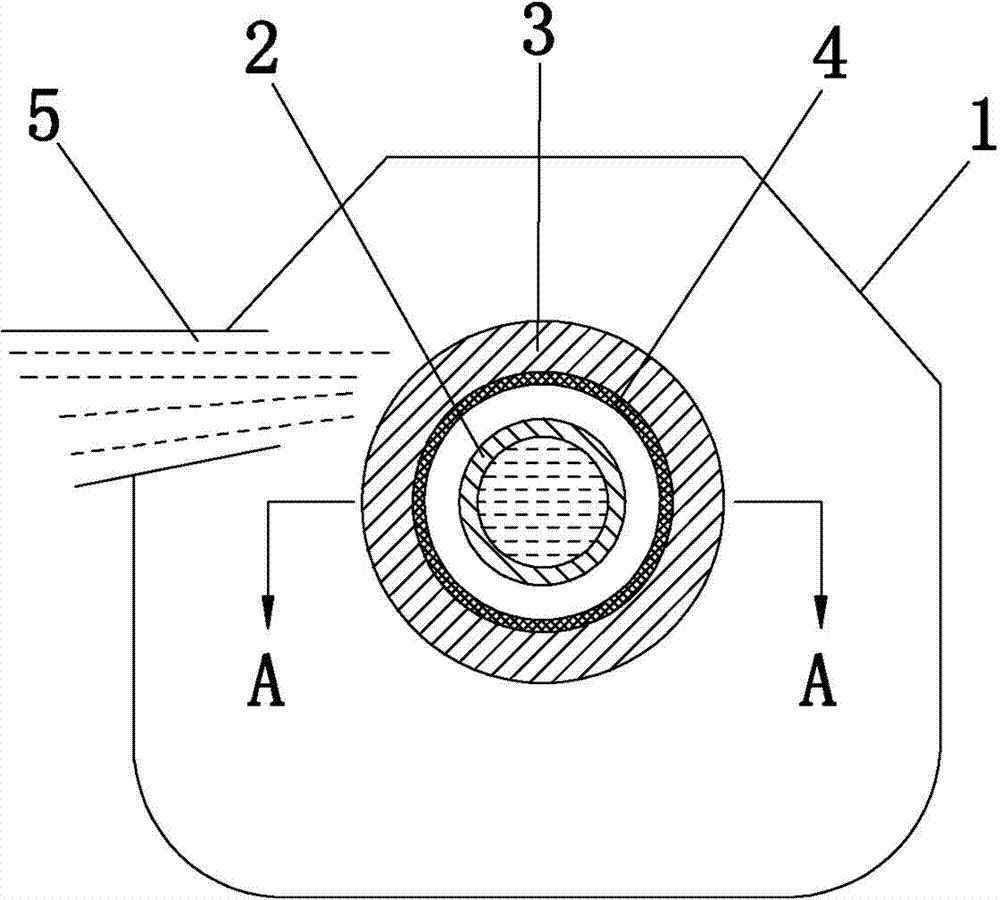

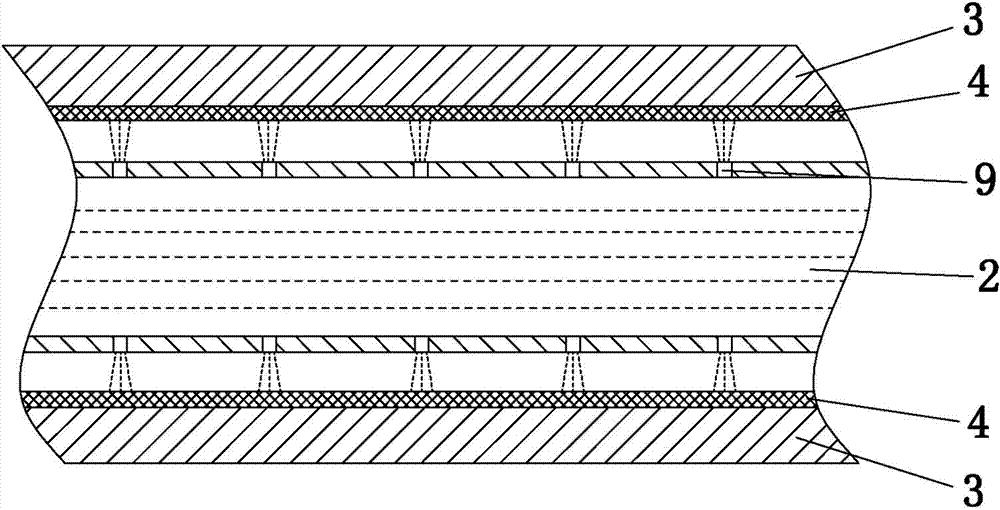

[0017] refer to Figure 1 to Figure 3 , a centrifugal non-contact wetting device for an offset printing press, used to supply water to the main water roller 6 of the offset printing press, the main water roller 6 transfers the water from the water roller group 7 to the printing plate on the printing plate cylinder 8. , the wetting device includes a water bucket 1, the water bucket is close to a closed shape, and only a water spray port 5 is provided at the position of the water bucket 1 facing the main water roller 6, and a mesh cylinder is installed in the water bucket 1 3, this net cylinder 3 is suitable for the belonging cylinder of the perforated net such as stainless steel, the inner wall of the net cylinder 3 is provided with a water-absorbing material layer 4, and the water-absorbing material layer 4 is a water-absorbing water fleece attached to the inner wall of the net cylinder 3. set. The water bucket 1 is provided with a water spray device. The water spray device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com