Passive oil conveying pipeline cleaner

A technology for oil pipelines and pigs, which is applied in the direction of cleaning hollow objects, cleaning methods and appliances, chemical instruments and methods, etc. It can solve problems such as high pollution, need to stop production, and low efficiency, so as to ensure oil transportation efficiency and prevent jamming The effect of blocking accidents and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

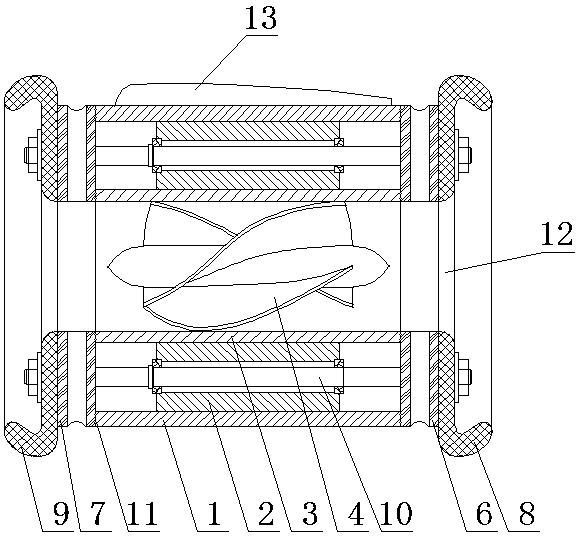

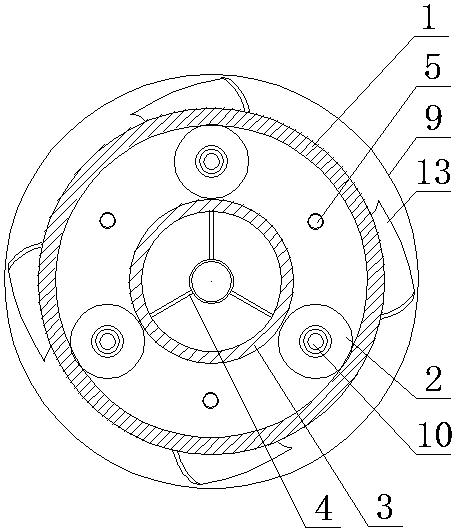

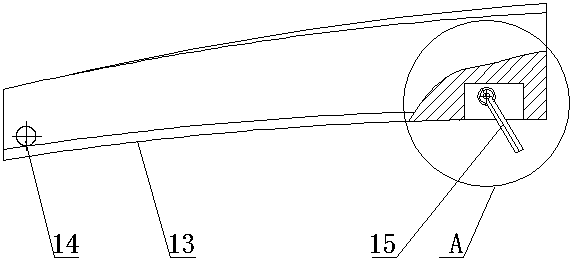

[0024] The passive oil pipeline pig includes a sun gear 1 , a planetary gear 2 , a sun gear 3 and an impeller 4 . The two ends of the sun gear 1 are respectively equipped with a front sealing plate 6 and a rear sealing plate 7 through a fixed rod 5 .

[0025] The outer sides of the front sealing plate 6 and the rear sealing plate 7 are respectively fixed with a front leather cup 8 and a rear leather cup 9 made of silica gel material. A central hole 12 is respectively arranged on the front sealing plate 6 , the rear sealing plate 7 , the front leather cup 8 and the rear leather cup 9 .

[0026] A planet gear shaft 10 is installed in the sun gear 1 between the front sealing plate 6 and the rear sealing plate 7 in a triangular shape through the front sealing plate 6 and the rear sealing plate 7 . Planetary gears 2 are movably installed on the planetary gear shafts 10 respectively, and a sun gear 3 is housed in the sun gear 1 between the planetary gears 2 . Balls 11 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com