Push switch structure far away from hot spot

A switch structure and switch technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of increased overall cost, inability to effectively reduce the volume, and dislike of users, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

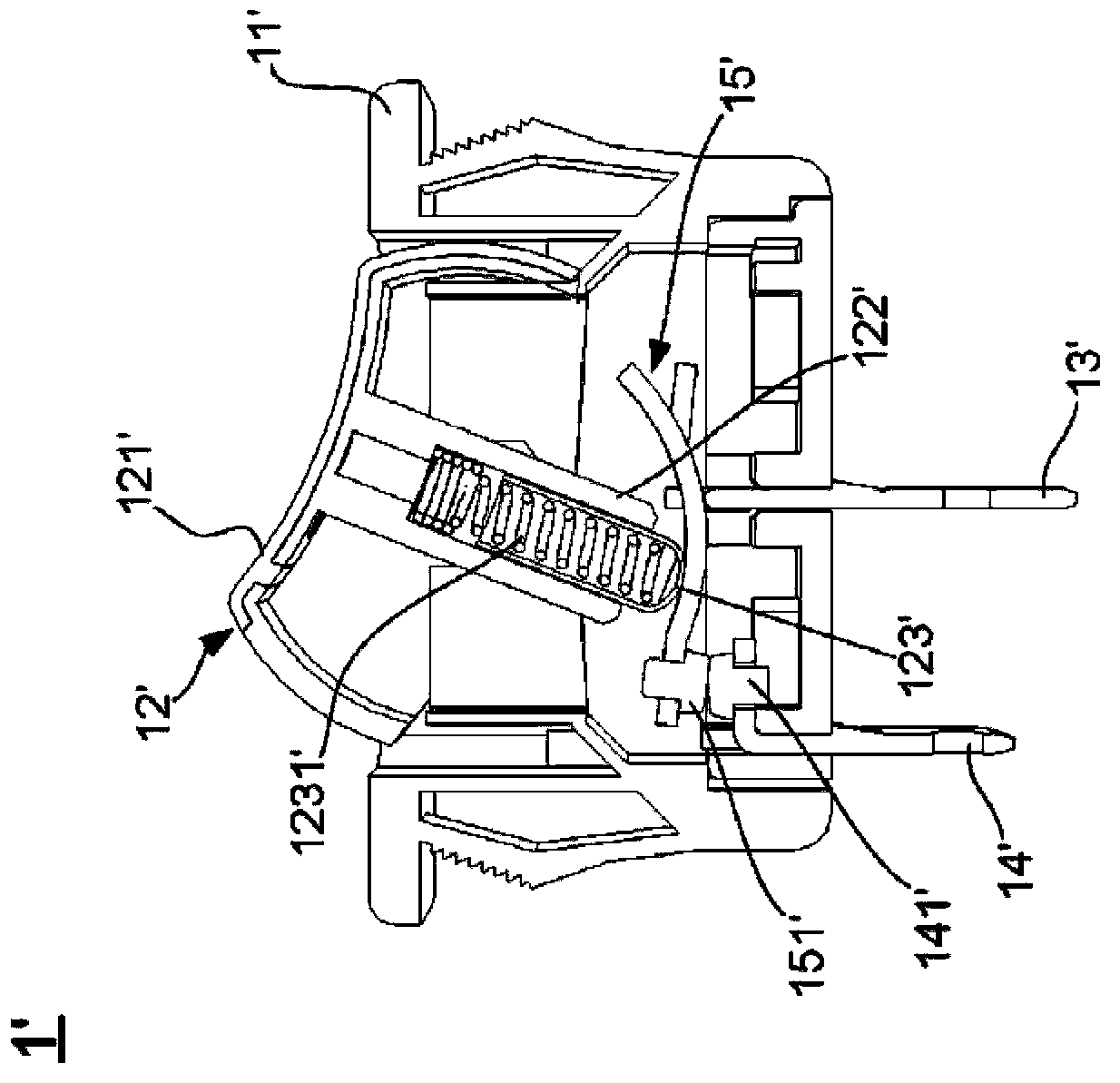

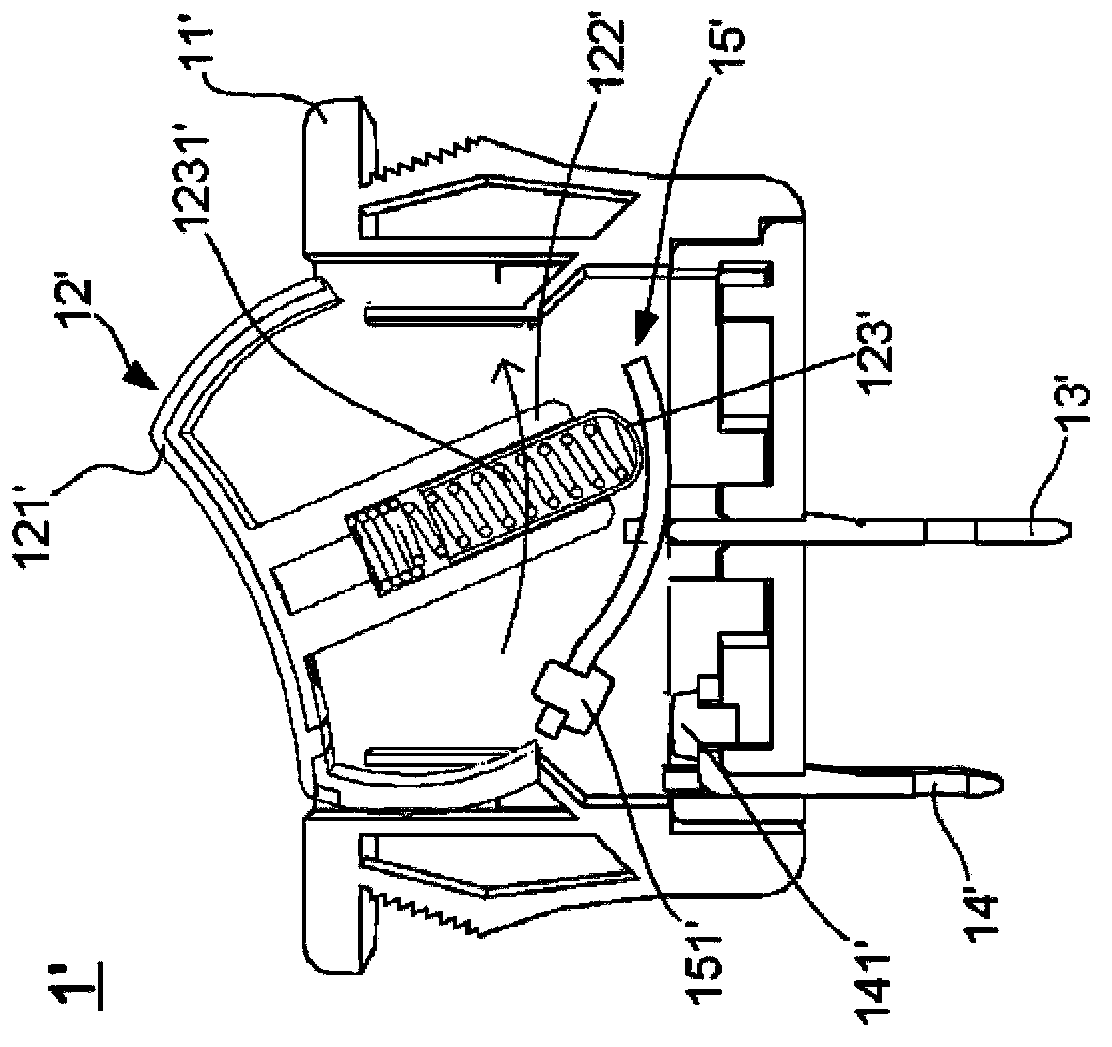

[0082] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation and structure of a push switch structure with hot spots away from the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , features and their effects are described in detail below.

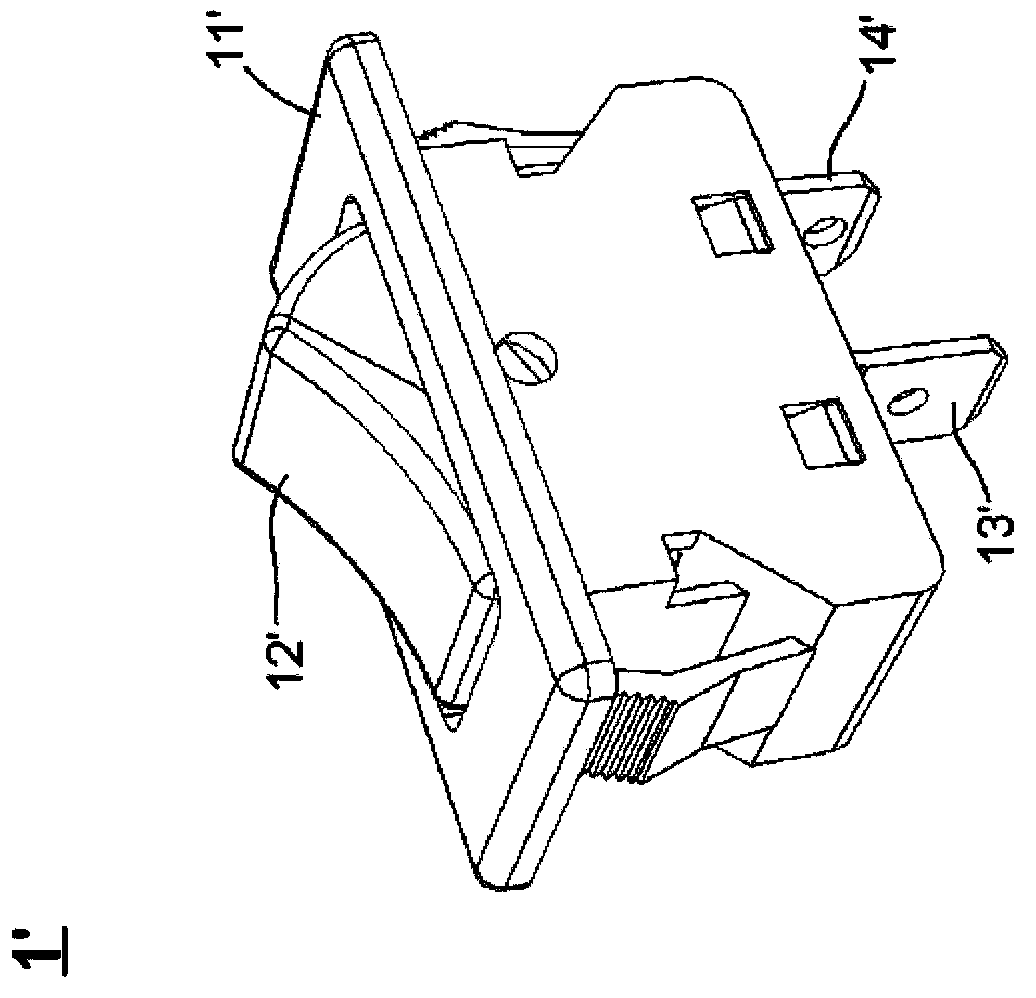

[0083] read on Figure 7 and Figure 8 , is a perspective view and an exploded view of the structure of the push switch away from the hot spot of the present invention. Such as Figure 7 and Figure 8 As shown, the push switch structure 1 of the present invention, which is away from hot spots, includes: a support terminal 11, a compression spring 12, a switch shrapnel 13, an electrical terminal 14, a switch slide bar group 15, a slide bar return spring 16, and a return spring fixing seat 17 ; Wherein, one end of the compression spring 12 is connected to the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com