Self-adaptive layering method in 3D (three-dimensional) printing

A 3D printing, self-adaptive technology, applied in the direction of digital output to printing unit, special data processing application, image data processing, etc. Achieving, robust effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

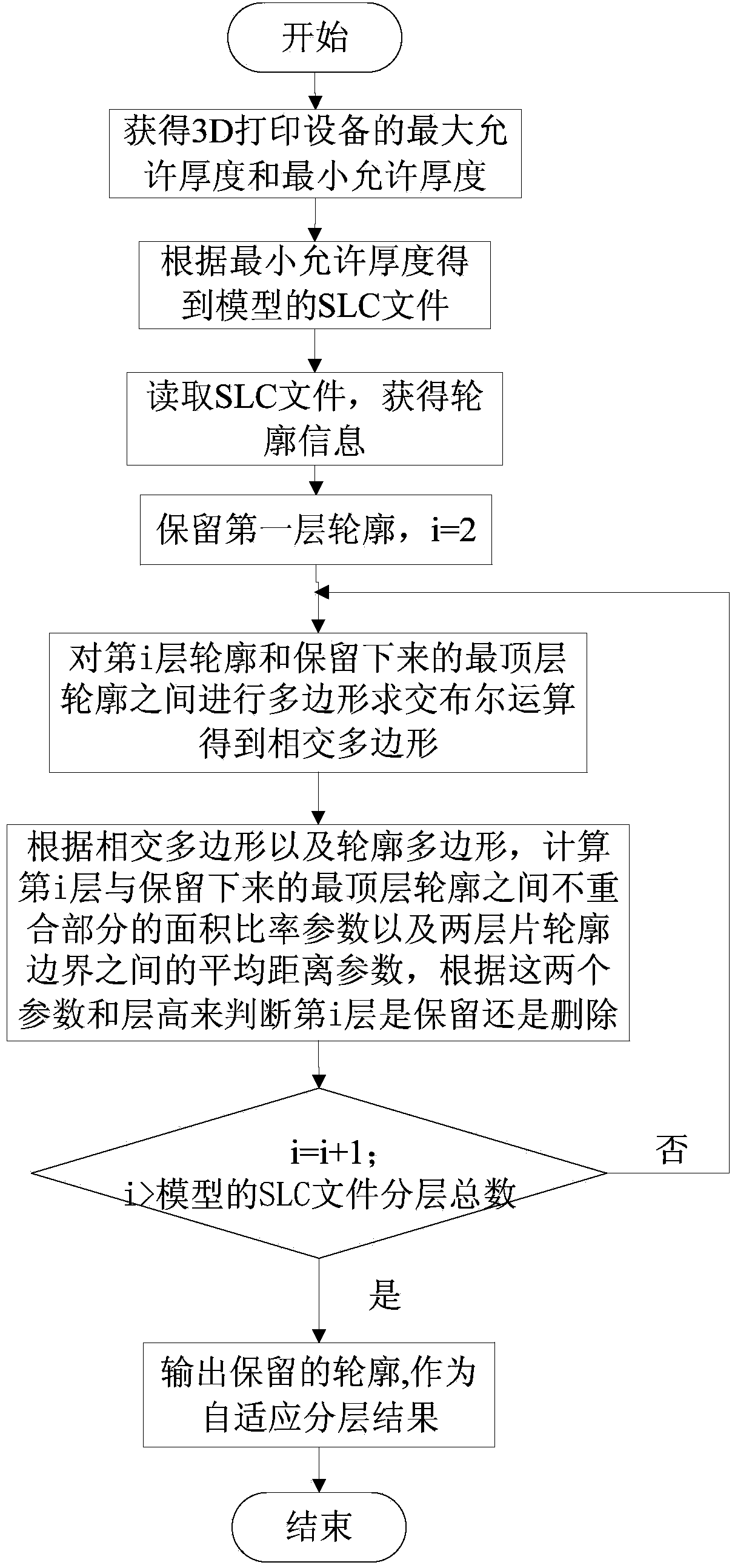

[0034] attached figure 1 Shown is the flow chart of the general adaptive layering method of the 3D printing technology of the present invention. A model of the rear wheel of a car is taken as an example to illustrate the adaptive layering method.

[0035] Step 1. Obtain a 3D printing device (a SLA device) with a maximum allowable layer thickness of 0.2mm and a minimum allowable layer thickness of 0.05mm;

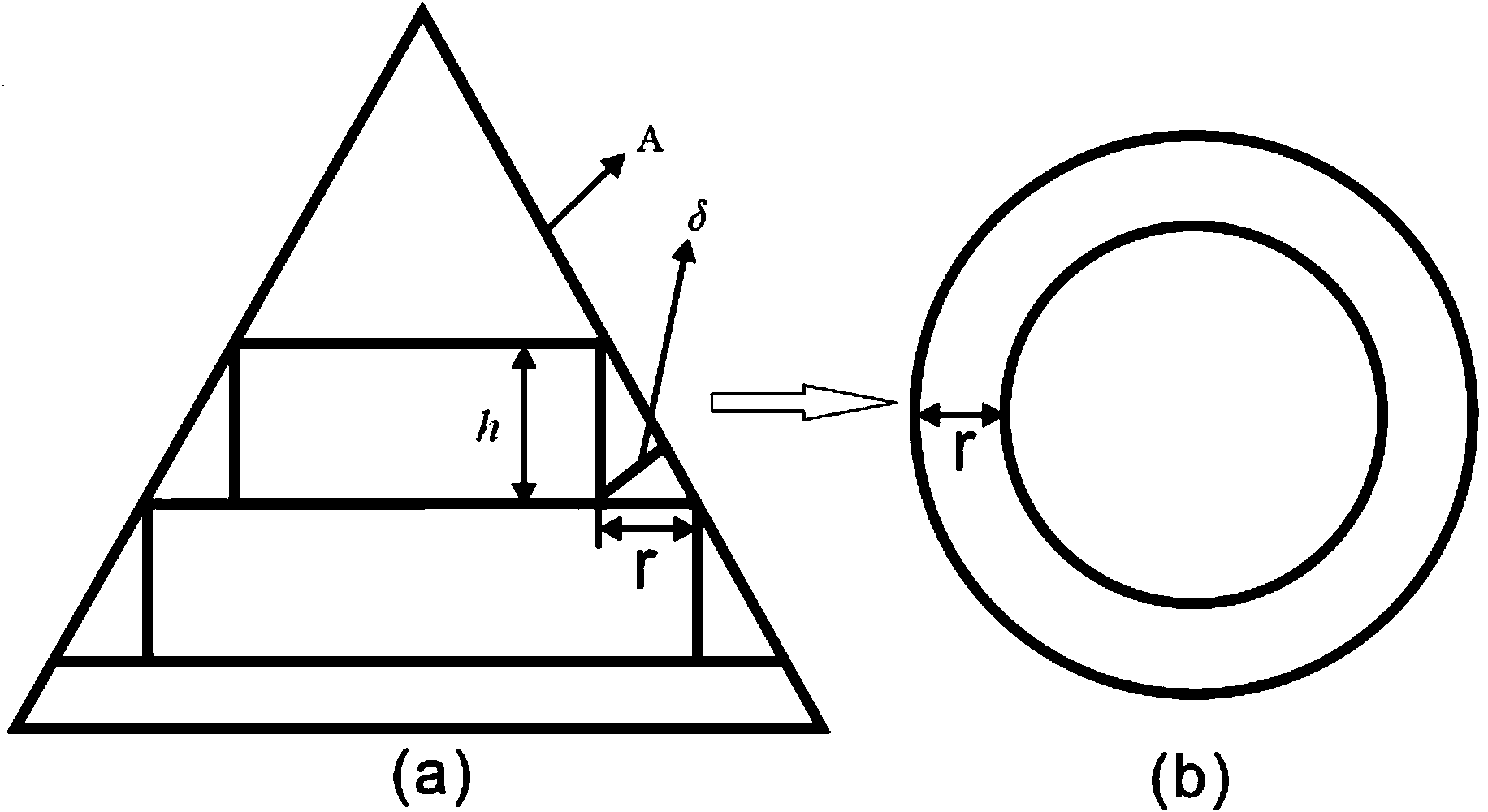

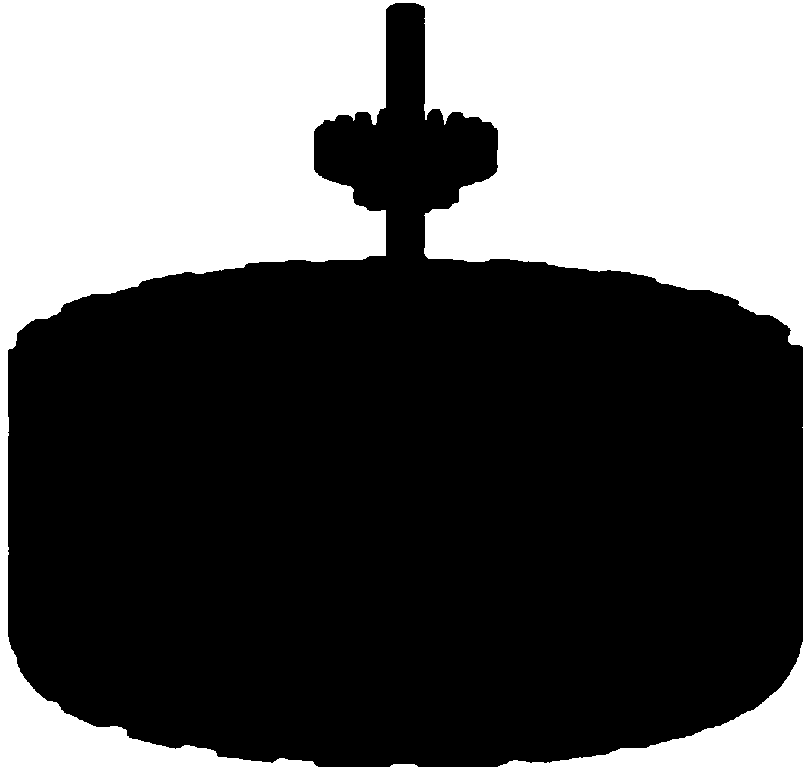

[0036] Step 2. Use the slicing software MagicRP to obtain the SLC file of the rear wheel of the car shown in Figure 3 (a), the layer thickness is 0.05mm, and Figure (b) is the obtained SLC model of the rear wheel;

[0037] Step 3. Read the rear wheel SLC file to obtain the rear wheel contour information, including the total number of layers n=400, the polygon set of each layer contour and the corresponding layer height, and the layer height i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com