Apparatus and method for gradient temperature control

A gradient temperature and constant temperature control technology, which is applied in the direction of temperature control using electric means, biochemical equipment and methods, biochemical cleaning devices, etc., can solve the problems of overshoot, shortening the service life, affecting the heating and cooling rate of the sample module, etc. , to achieve the effect of flexible temperature control, extended service life and scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

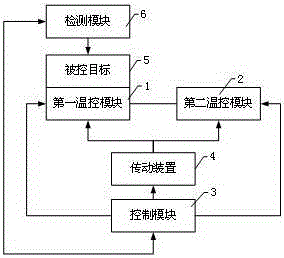

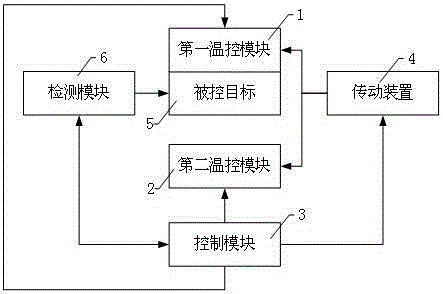

[0027] see Figure 1-4 , a translational device suitable for gradient PCR reactions based on the principle of time-division multiplexing of temperature control modules, consisting of a first temperature control module 1, a second temperature control module 2, a control module 3, a transmission device 4, and a controlled target 5 Composed of a detection module 6, the first temperature control module 1 and the second temperature control module 2 are connected to the transmission device 4, and the transmission device 4 controls different temperature control modules to move or rotate and physically contact the controlled target 5. The control module 3 and the The transmission device 4 is connected, and the control module 3 outputs control signals to control the transmission device 4 to generate corresponding actions. The signal controls the temperature control module to realize temperature changes. The detection module 6 is connected to the controlled target 5. The detection modul...

Embodiment 2

[0033] see figure 1 and figure 2 , is a schematic structural view of two PCR thermal cyclers based on the present invention, because the transmission device 4 in the two examples realizes the controlled target 5 and the temperature control module (the first temperature control module 1, the second temperature control module 2 ) linear motion in physical contact, so they are explained together. The difference between the two is figure 1 Using translational transmission, figure 2 Use the longitudinal transmission device, which can be selected according to actual needs. The two PCR thermal cyclers mainly include a control module 3 , a first temperature control module 1 , a second temperature control module 2 , a transmission device 4 , a controlled target 5 and a detection module 6 .

[0034] The temperature control modules (the first temperature control module 1 and the second temperature control module 2 ) include a heating module, a cooling module, a heat dissipation mod...

Embodiment 3

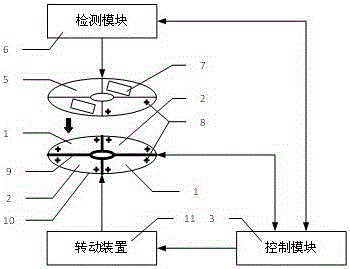

[0044] see image 3 , Figure 4 , is a structural schematic diagram of a disc-type PCR thermal cycler based on the present invention, the corresponding device uses a rotating device 11 to realize rotational positioning, and realizes the controlled target 5 and the temperature control module (the first temperature control module 1, the second temperature control module physical contact with the control module 2). It should be noted that the shapes of the controlled target 5 and the temperature control module suitable for the rotating device 11 are not limited to the shape of a disc, but can also be fan-shaped, diamond-shaped, square, polygonal, and irregular polygonal, etc. Figure 4 It is a top view structure schematic diagram of a supporting sample loading disc. Figure 7 (Patent: CN102277294B figure 2 ) is a schematic diagram of an integrated flow chip suitable for performing digital PCR reactions in the device of the present invention. The integrated flow path chip mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com