Support fine-tuning device applied to pre lens optical axis alignment

A technology of fine-tuning device and front mirror, which is applied in installation, optics, optical components, etc., can solve the problems of inconvenient movement, inability to adjust the height direction, high cost, etc., and achieve simple structure, convenient adjustment and operation, and a small number of parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

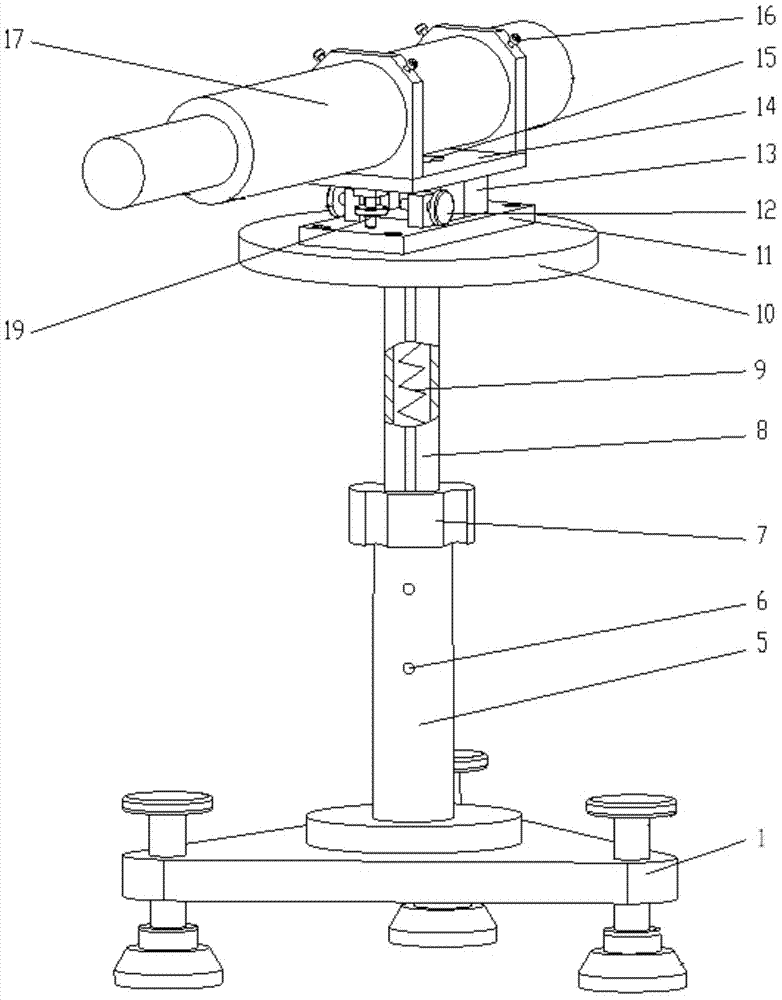

[0019] Such as figure 1 As shown, the support fine adjustment device provided by the preferred embodiment of the present invention includes an adjustment platform 1, a lifting assembly and an angle fine adjustment assembly.

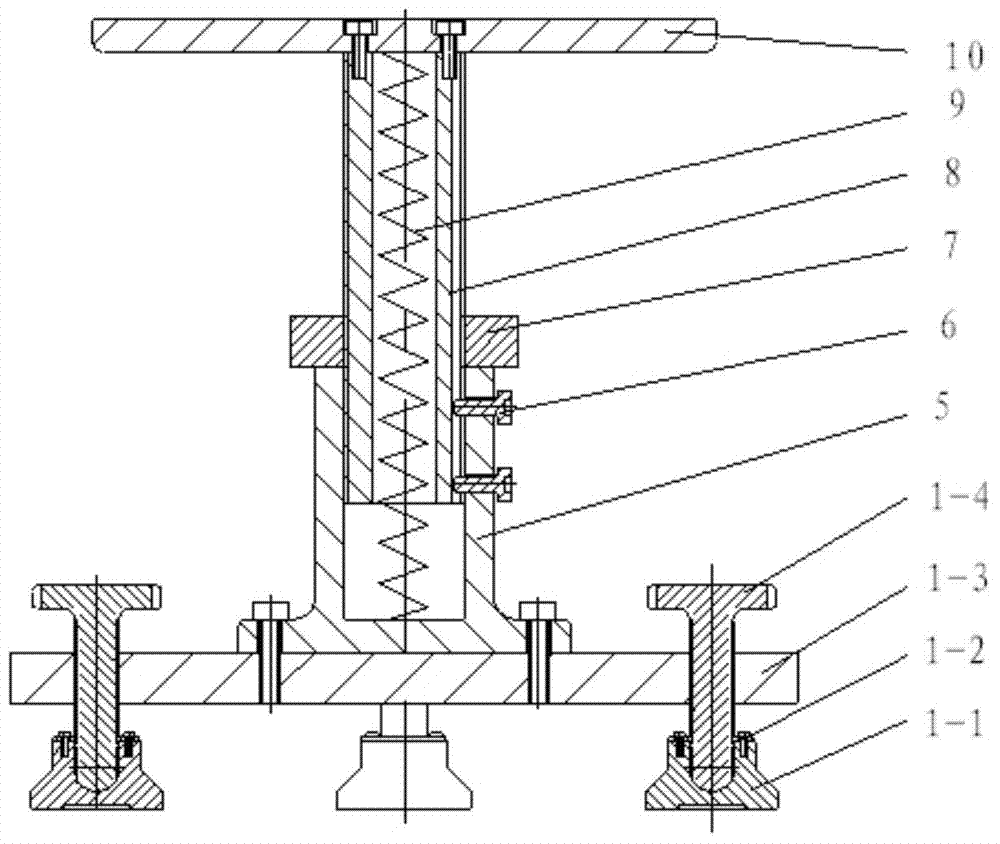

[0020] Such as figure 2 As shown, the adjusting platform 1 has a triangular platen 1-3 and three adjusting angle screws. The middle part of the triangular platen 1-3 is provided with a set of screw holes, and the three top corners are respectively provided with a threaded hole; the three adjusting angle screws are composed of three supporting seats 1-1, three cards 1-2, and three adjusting screws. Composed of 1-4 handwheels. Adjusting hand wheel 1-4 is a T-shaped structure, with anti-slip straight knurling on the raised part of the upper end, threaded on the lower end and connected with the threaded hole of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com