Differential air drilling coring device and method

An air drilling and coring device technology is applied in the direction of extracting undisturbed cores, earthwork drilling, etc., which can solve the problems of unsatisfactory sampling effect and inability to meet the needs of drilling and coring, so as to improve the core harvest rate and reduce scouring. , the effect of improving core quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

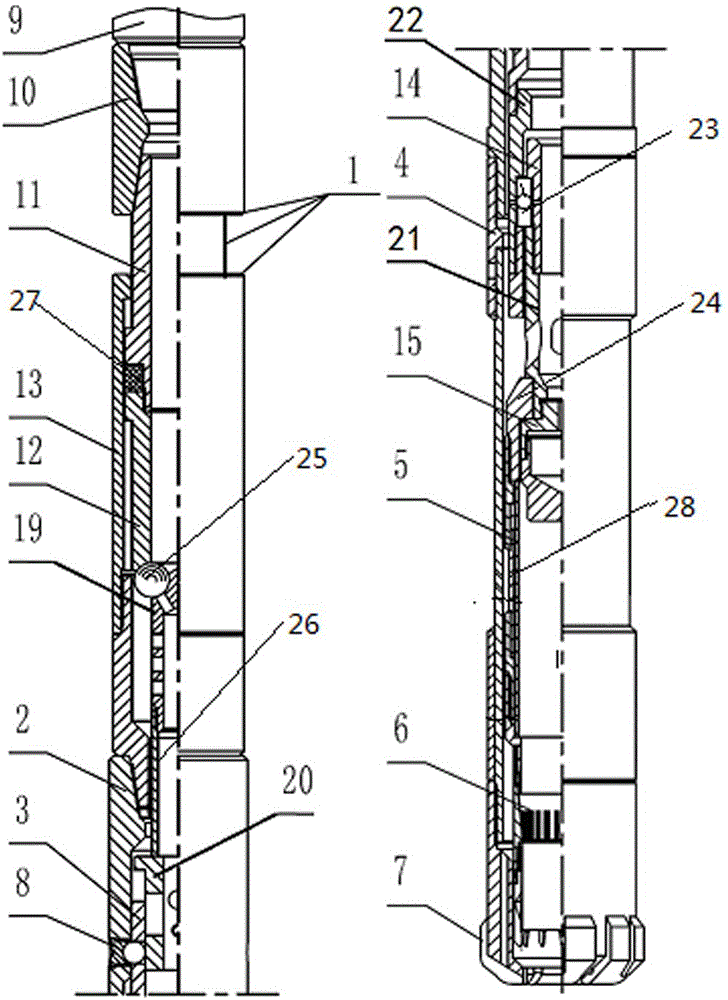

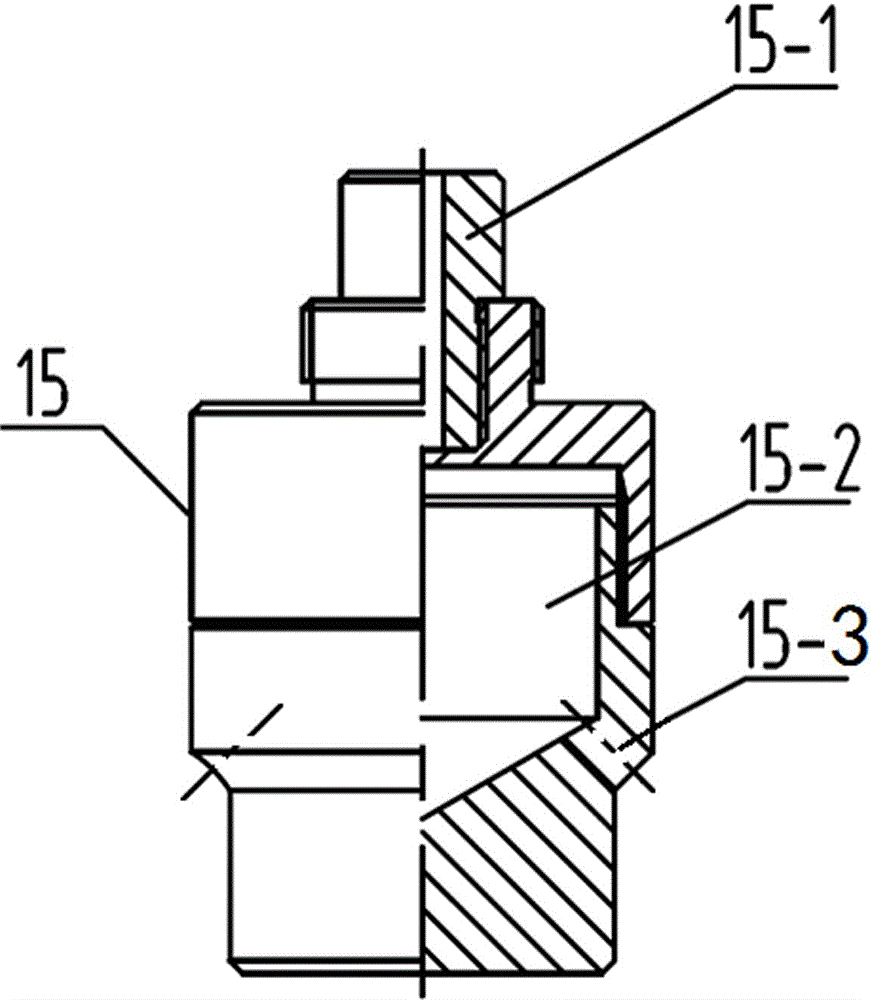

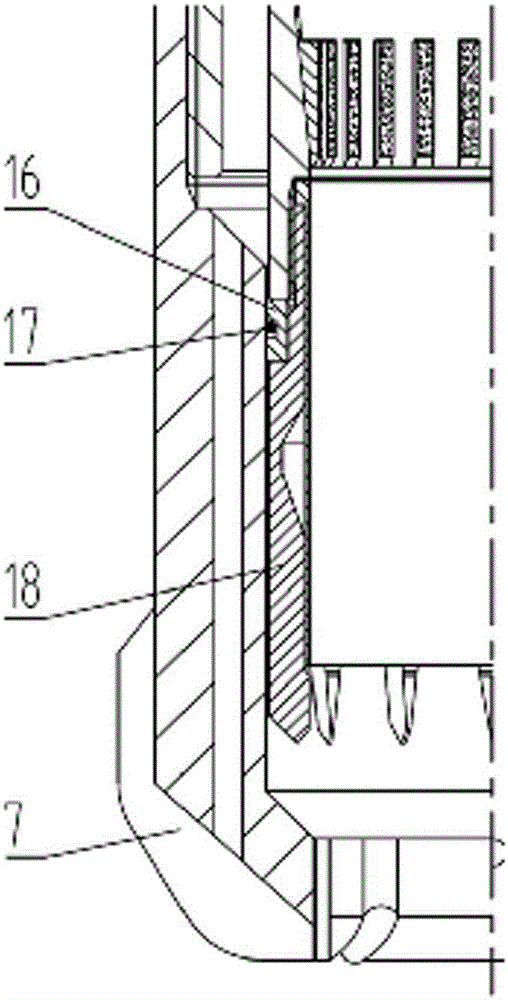

[0023] Refer to attached figure 1 , the differential mechanism 1, the positioning pup joint 2, the outer cylinder assembly 4, and the coring bit 7 are connected together from top to bottom by threads to form an outer cylinder combination, and the suspension assembly 3, the inner cylinder assembly 5 and the core cutting mechanism 6 pass through The threads are connected up and down to form an inner cylinder combination. The differential mechanism 1 includes an inner polygon 11, an outer polygon 13, an upper joint 10 and a pressure joint 12. The drilling tool 9, the upper joint 10, the inner polygon 11 and the pressure joint 12 are sequentially connected by threads, and the outer polygon 13 The inner polygonal body 11 is set outside, and the inner polygonal body 11 and the outer polygonal body 13 are provided with mutually limiting ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com