Method for preventing two-way hydraulic shock absorber from withdrawing and shock absorber

A two-way hydraulic pressure and shock absorber technology, which is applied in the direction of earthwork drilling, drilling equipment, drill pipe, etc., can solve the problems that the lower drilling tool falls off the bottom of the well, the mandrel and the outer cylinder of the centering fall out, affecting the drilling progress and economic benefits, etc. , to achieve the effect of eliminating relative rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

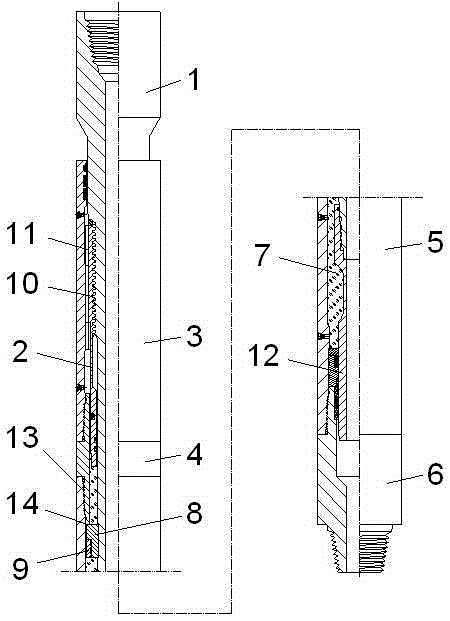

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

[0023] Methods to prevent two-way hydraulic shock absorbers from backing out, such as figure 1 shown. The two-way hydraulic shock absorber is mainly composed of a longitudinal shock absorbing mechanism and a piston reversing mechanism. The piston reversing mechanism converts the rotational impact load into longitudinal component force and Torque, the vibration caused by the longitudinal component is slowed down by the longitudinal shock absorbing mechanism, and the torque is transmitted to the limit assembly; the method is to set the limit assembly at the lower end surface of the connecting body 4 in the outer casing of the two-way hydraulic shock absorber; the connecting body 4 The torque transmission thread 13 is used to connect with the oil cylinder 5, and the torque transmission thread 13 between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com