Method for promoting residual sludge to be anaerobically fermented to produce acid by utilizing tea saponin

A technology of excess sludge and anaerobic fermentation, applied in fermentation and other directions, can solve the problems of insufficient improvement of anaerobic acid production effect, high cost of microbial fermentation, poor biodegradability, etc. Simple effects of industrial extraction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

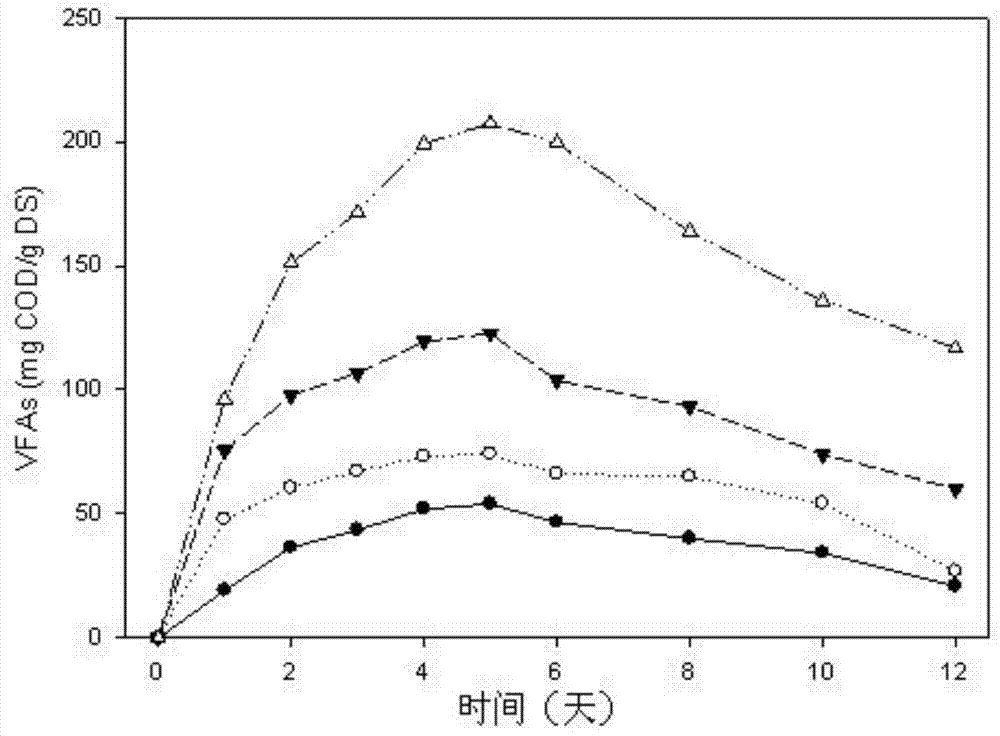

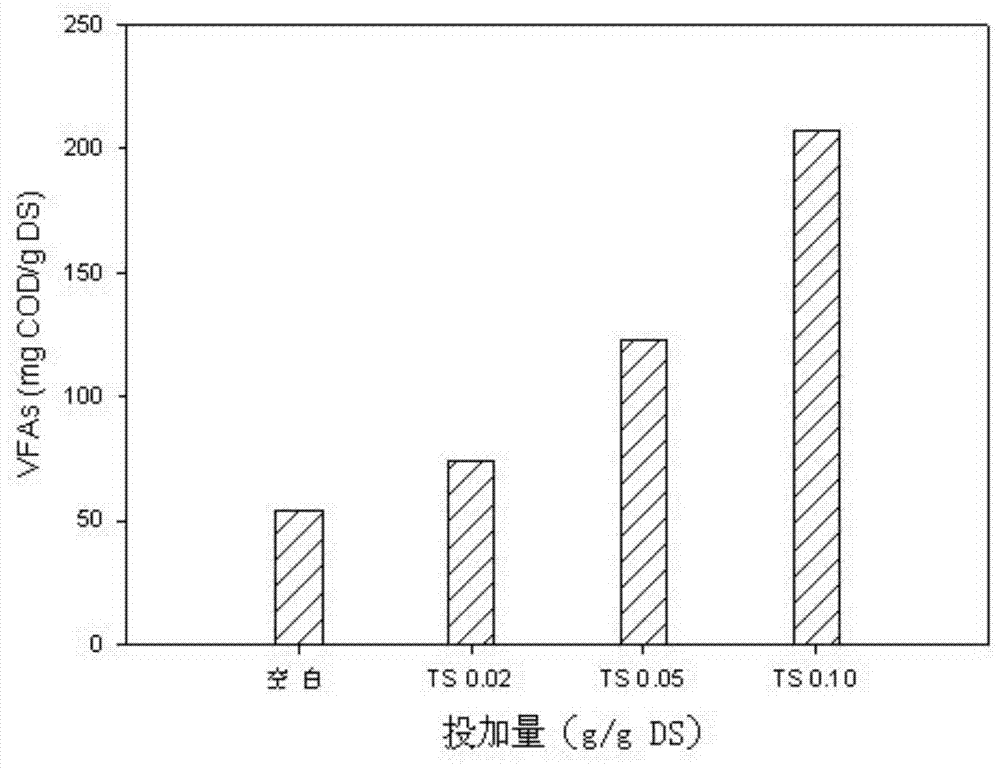

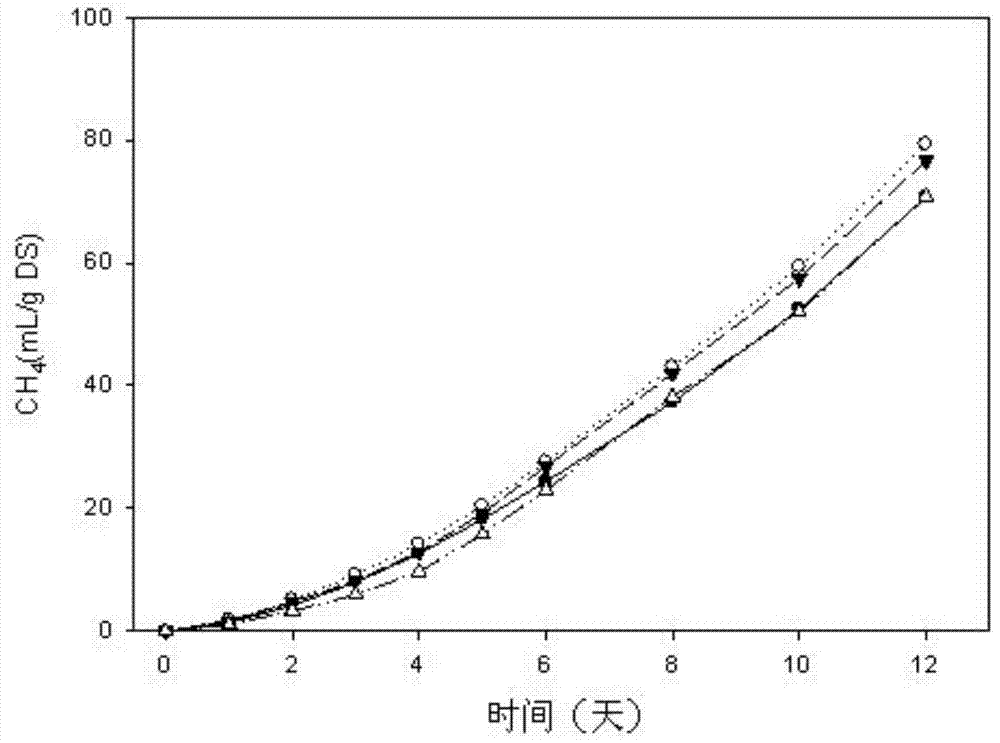

Embodiment 1

[0025] Let the remaining sludge settle at 4°C for 12-24 hours until the concentration of the concentrated sludge in the lower layer is between 10-20g / L, remove the supernatant, and take 300mL of concentrated sludge into a 1L anaerobic fermentation tank ;

[0026] With the supernatant that last step obtains, tea saponin is dissolved and formulated into the concentration of 40g / L;

[0027] According to the actual concentration of the concentrated sludge, add tea saponin to the fermenter according to the dosage of 0.02g (tea saponin) / g (dried sludge), and mix quickly and uniformly;

[0028] Feed 10 times of the tank volume of nitrogen into the fermenter to remove the oxygen in the tank, then start to carry out anaerobic fermentation to the remaining sludge, and keep the fermenter airtight during the anaerobic fermentation process;

[0029] During the fermentation process, the temperature in the fermenter is maintained between 28-30°C, the mixing speed is between 100-120rpm, and ...

Embodiment 2

[0033] Let the remaining sludge settle at 4°C for 12-24 hours until the concentration of the concentrated sludge in the lower layer is between 10-20g / L, remove the supernatant, and take 300mL of concentrated sludge into a 1L anaerobic fermentation tank ;

[0034] With the supernatant that last step obtains, tea saponin is dissolved and formulated into the concentration of 40g / L;

[0035] According to the actual concentration of the concentrated sludge, add tea saponin to the fermenter according to the dosage of 0.05g (tea saponin) / g (dry sludge), and mix quickly and uniformly;

[0036] Feed 10 times of the tank volume of nitrogen into the fermenter to remove the oxygen in the tank, then start to carry out anaerobic fermentation to the remaining sludge, and keep the fermenter airtight during the anaerobic fermentation process;

[0037] During the fermentation process, the temperature in the fermenter is maintained between 28-30°C, the mixing speed is between 100-120rpm, and th...

Embodiment 3

[0041] Let the remaining sludge settle at 4°C for 12-24 hours until the concentration of the concentrated sludge in the lower layer is between 10-20g / L, remove the supernatant, and take 300mL of concentrated sludge into a 1L anaerobic fermentation tank ;

[0042] With the supernatant that last step obtains, tea saponin is dissolved and formulated into the concentration of 40g / L;

[0043] According to the actual concentration of the concentrated sludge, add tea saponin to the fermenter according to the dosage of 0.10g (tea saponin) / g (dry sludge), and mix quickly and uniformly;

[0044] Feed 10 times of the tank volume of nitrogen into the fermenter to remove the oxygen in the tank, then start to carry out anaerobic fermentation to the remaining sludge, and keep the fermenter airtight during the anaerobic fermentation process;

[0045] During the fermentation process, the temperature in the fermenter is maintained between 28-30°C, the mixing speed is between 100-120rpm, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com