A kind of inferior raw material hydrogenation processing method

A hydroprocessing and raw material technology, which is applied in hydroprocessing process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problem of harsh operating conditions of wax oil hydroprocessing unit, limited circulation of catalytic cracking heavy cycle oil, and inability to guarantee the equipment Long-term operation and other problems, to reduce the clogging of catalyst pores, improve the effect of impurity removal, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

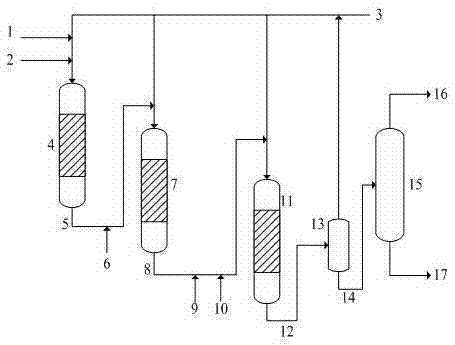

Embodiment 1

[0028] Example 1 adopts figure 1 In the process shown, the properties of deasphalted oil (DAO), catalytic oil slurry, coker wax oil (CGO), vacuum gas oil (VGO) and catalytic diesel oil used are shown in Table 1. The protective agent in the hydrodemetalization reaction zone is the FZC100, FZC102B, and FZC103 catalysts developed by Fushun Petrochemical Research Institute. The demetalization catalyst is FZC-204 catalyst. The desulfurization, denitrogenation and hydrofining in the first hydroprocessing reaction zone The catalyst is the FF-24 hydrogenation catalyst developed by Fushun Petrochemical Research Institute. The desulfurization, denitrogenation and hydrofining catalyst in the second hydroprocessing reaction zone is the FF-46 hydrogenation catalyst developed by Fushun Petrochemical Research Institute. The properties are shown in Table 2. The hydrorefining catalysts in the first and second hydrotreating reaction zones adopt dense-phase packing. The process conditions of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com