Ultraviolet-curable high-transparency permanent antistatic coating

An ultraviolet light and antistatic technology, applied in the direction of coating, etc., to achieve the effects of easy processing and construction, improved durability, and excellent antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

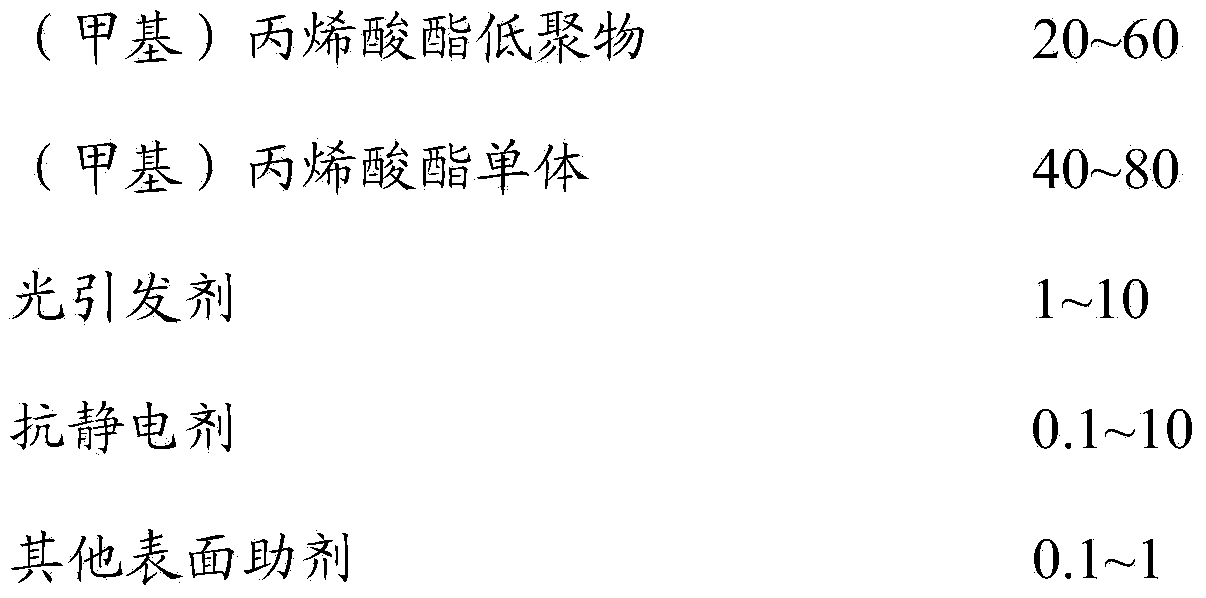

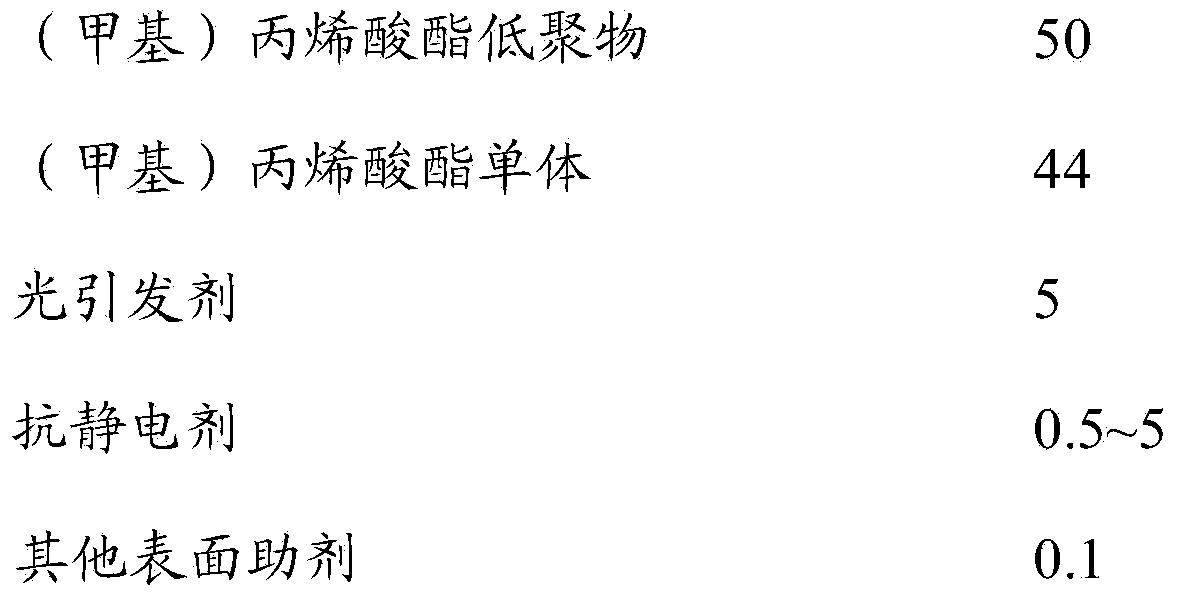

Method used

Image

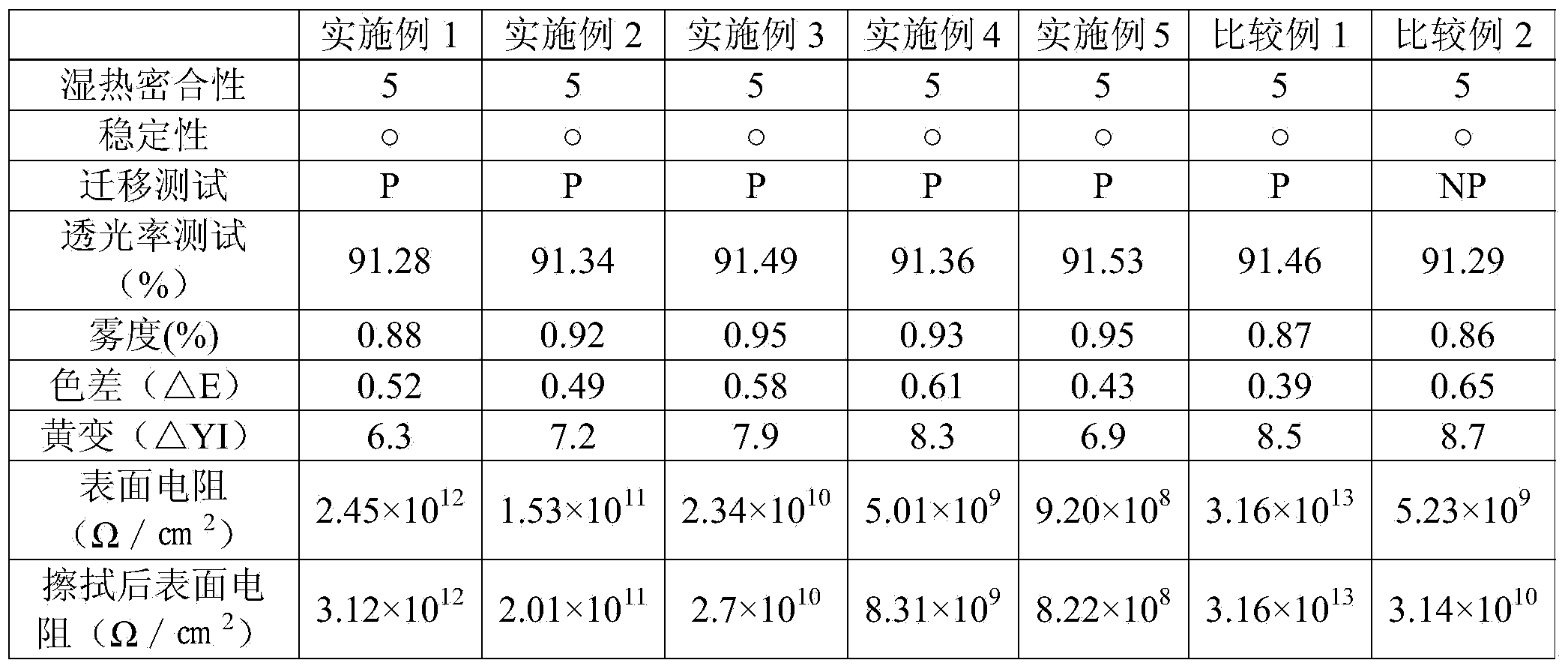

Examples

Embodiment 1~5 and comparative example 1~2

[0030] Add acrylate monomer, photoinitiator, acrylate oligomer, surface additive, and antistatic agent sequentially according to the ratio shown in Table 1, mix and disperse evenly at 30-50°C until it becomes a transparent liquid.

[0031] CN-9006NS obtained from Sartomer Company was used as acrylate oligomer A1;

[0032] CN-9001NS obtained from Sartomer Company was used as acrylate oligomer A2;

[0033] EM210 obtained from Changxing Chemical Co., Ltd. was used as acrylate monomer B1;

[0034] EM3265 obtained from Changxing Chemical Co., Ltd. was used as acrylate monomer B2;

[0035] EM221 obtained from Changxing Chemical Co., Ltd. was used as acrylate monomer B3;

[0036] Dimethyloctadecylallylamine bis(perfluoroethanesulfonyl)imide obtained from the market was used as antistatic agent C;

[0037] Irgacure184 and Irgacure TPO obtained from Ciba were used as initiator D;

[0038] As surface additive E, BYK-3530 obtained from BYK Chemie Co., Ltd. was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com