Filtering tip material made of porous foam for cigarettes and preparation method thereof

A technology for porous foaming and cigarette use, which is applied in the direction of e-liquid filter, application, tobacco, etc., can solve the problems of uneven pores of foamed materials, high melting temperature, and it is difficult to apply the material to filter rods. The process is simple and the application prospect is broad.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

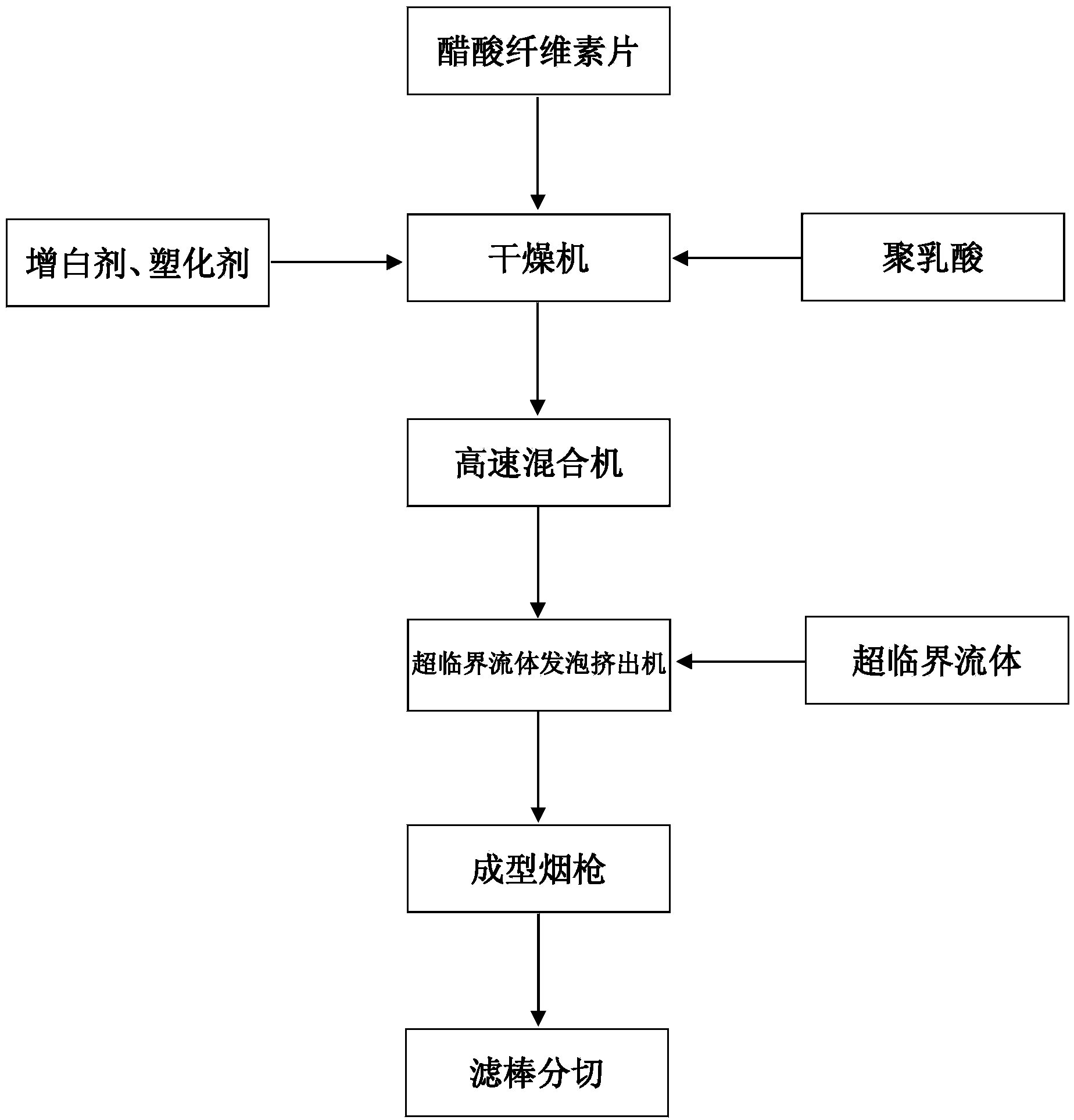

[0021] The porous foam cigarette filter material of the present invention is prepared by supercritical fluid foaming and melting extrusion, such as figure 1 Shown, the preparation method of porous foam cigarette filter material of the present invention comprises the steps:

[0022] 1) Put 70-88 parts by weight of cellulose acetate sheet, 1-10 parts by weight of polylactic acid, 6-25 parts by weight of plasticizer and 0.1-0.5 parts by weight of titanium dioxide into a dryer and dry until the moisture content is lower than 0.5 %, and then put it into a high-speed mixer and mix it thoroughly for 6-10 minutes. Wherein the raw material cellulose acetate sheet substitution degree is 2.0~2.7;

[0023] 2) Put the mixed material into the supercritical fluid foaming extruder, which includes the upper stage extruder, gas injection section, lower stage extruder and extruder head connected in sequence . The mixture first enters the upper-stage extruder, kneads and extrudes at a process ...

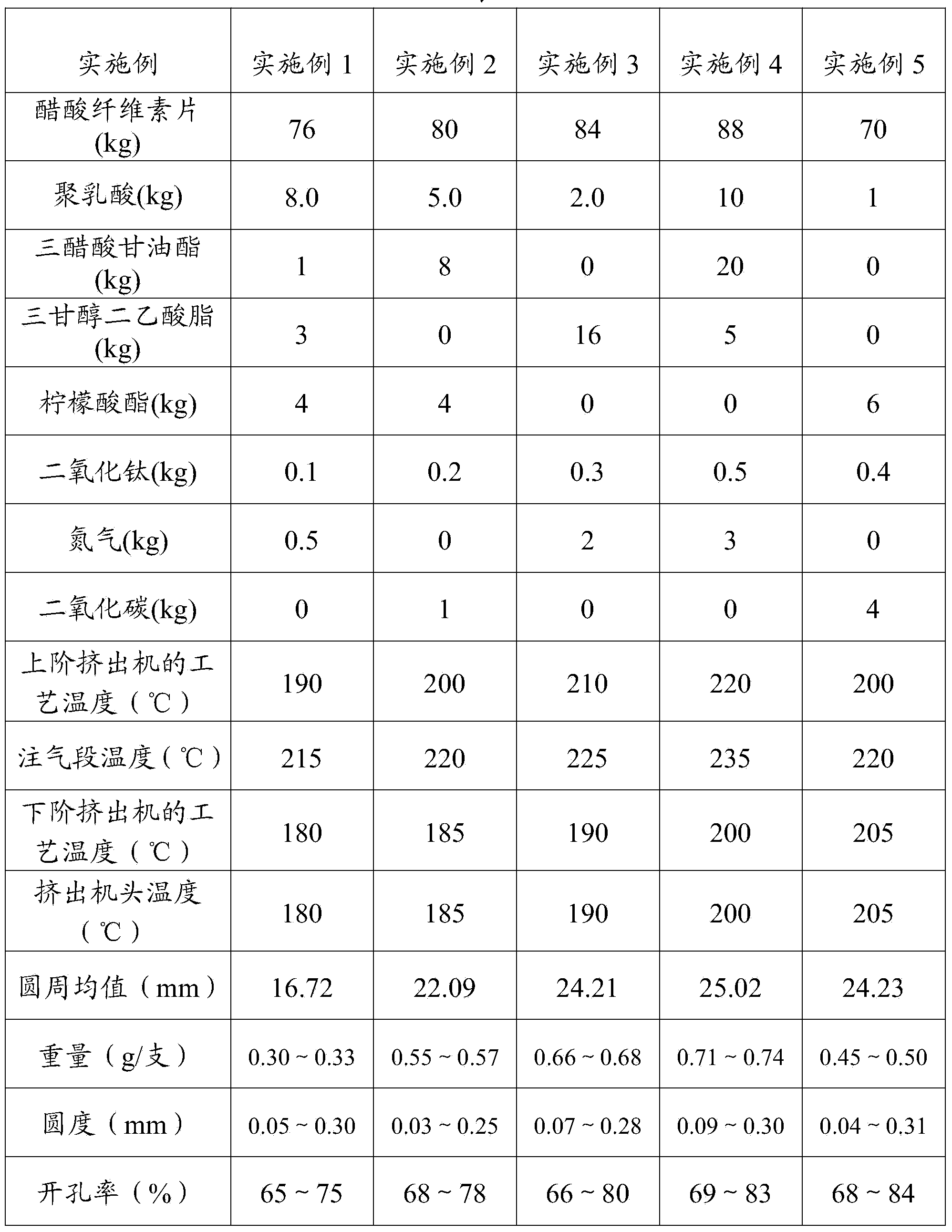

Embodiment 1~5

[0026] The cellulose acetate sheet, polylactic acid, titanium dioxide and plasticizer (triacetin, triethylene glycol diacetate, citric acid ester) according to the weight parts in Table 1 are mixed and extruded according to the above method, and the process parameters are shown in Table 1. Then, the cigarette filter rods with a length of 120 mm were obtained by sizing and cutting the formed bongs with different inner diameters. 20 filter rods were randomly selected to test the circumference, weight, roundness, opening ratio, cell density, and cell density. For pore size, suction resistance and hardness, the detection methods refer to relevant national standards, and the specific physical indicators are shown in Table 1.

[0027] Table 1

[0028]

[0029]

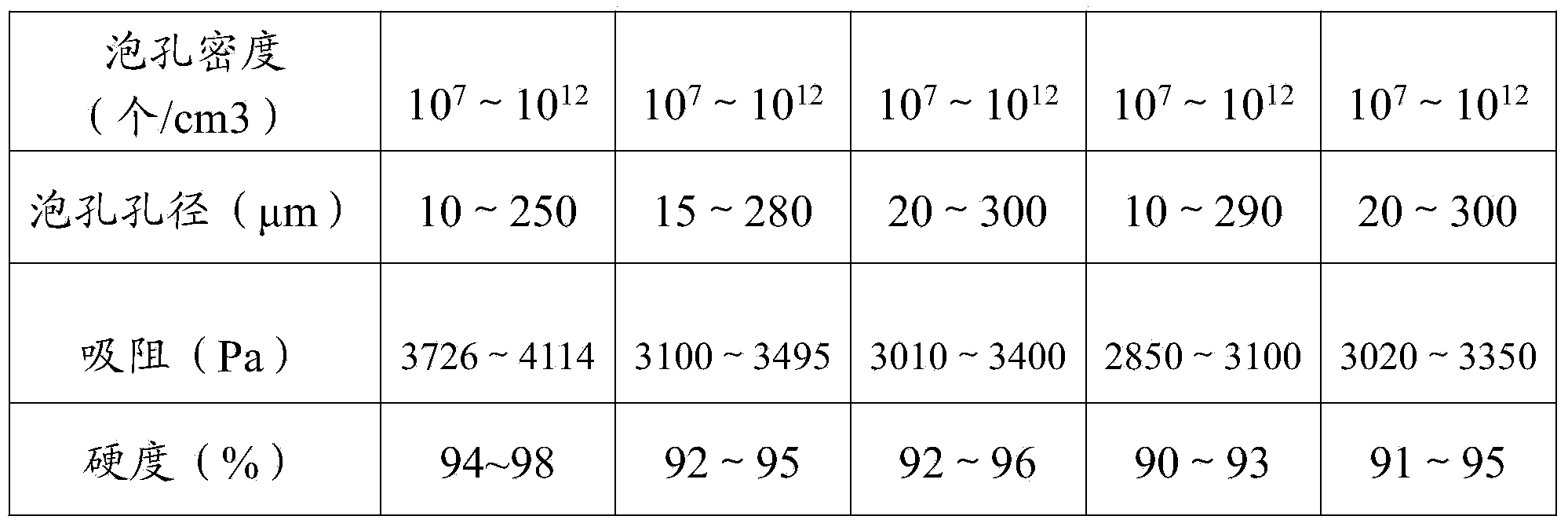

Embodiment 6~10

[0031] The filter sticks and shredded tobacco rolls made in Examples 1 to 5 are used to make sample cigarettes, and 50 cigarettes of each sample obtained are smoked at random, and the number of puffs of each cigarette is measured and averaged, and the smoke is measured. The tar content and total particulate matter in the final flue gas. The tar content and total particulate matter were determined according to GB / T19609-2004 "Determination of total particulate matter and tar by smoking machine for routine analysis of cigarettes". Cigarettes made of ordinary filter rods with the same circumference, draw resistance and length were used for comparative experiments, and the results are shown in Table 2.

[0032] Table 2

[0033] cigarette

[0034] Example 5

[0035] As can be seen from the above examples, the cigarette filter tip made of the foam material produced by the method for preparing the porous foam cigarette filter tip material of the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com