Embossed texture decorative mortar as well as preparation and construction methods thereof

A decorative mortar and embossing technology, which is applied in construction, building structure, and building material processing, etc. It can solve the problems of unfavorable special tool roller coating, embossing, embossed decorative mortar construction difficulty, decorative mortar easy to crack, etc. , to achieve the effect of elegant decoration, good anti-cracking effect and saving process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

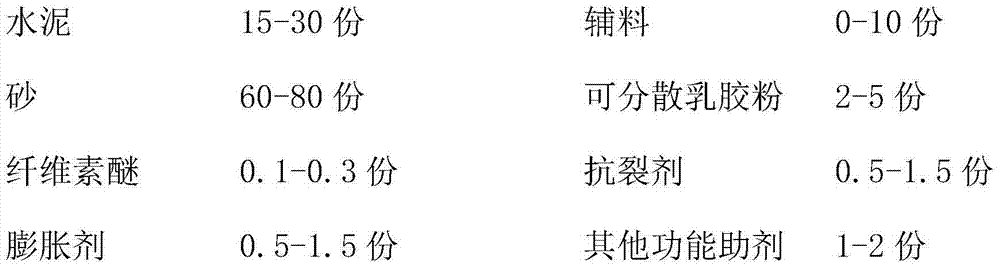

Method used

Image

Examples

Embodiment 1

[0020] An embossed textured decorative mortar, which is uniformly mixed in a dry mixer with the following components by weight: 20 parts of ordinary Portland cement, 2 parts of fly ash, 10 parts of 10-40 mesh magnesia sand, 28 parts of 40-80 mesh magnesia sand, 36 parts of magnesia sand of 80-120 mesh, 2 parts of vinyl acetate-ethylene copolymer latex powder, 0.2 part of carboxypropyl methyl cellulose ether, 0.6 part of polypropylene fiber, expansion agent 0.8 parts, 0.3 parts of water-repellent agent, and 0.1 parts of defoamer.

[0021] Wherein the expansion agent is an alum stone expansion agent;

[0022] The water-repellent agent is a publicly available commercially available water-repellent agent, such as the KY-1 water-repellent agent of Tianjin Keyuan New Building Materials Co., Ltd.; the defoamer is a publicly available commercially available defoamer, such as Shenzhen Haichuan Chemical Industry Co., Ltd. 1922 defoamer from Technology Co., Ltd.;

[0023] Preparation m...

Embodiment 2

[0026] An embossed textured decorative mortar, which consists of the following components by weight and is evenly mixed in a dry mixer: 18 parts of ordinary Portland cement, 2 parts of heavy calcium powder, 10 parts of 10-40 mesh quartz sand, 40 30 parts of ~80 mesh quartz sand, 36 parts of 80~120 parts of quartz sand, 2 parts of acrylic latex powder, 0.3 part of methyl cellulose ether, 0.3 part of polypropylene fiber, 0.5 part of wood fiber, 0.6 part of expansion agent, 0.3 part of water repellent share.

[0027] Wherein the expansion agent is calcium sulfoaluminate expansion agent;

[0028] The preparation method is the same as in Example 1.

[0029] Construction method: (1) Add water to the textured decorative mortar and mix until it is evenly mixed; the amount of water added is 19.5% of the weight of the mortar. (2) Apply the mixed embossed texture decorative mortar to the wall in batches, and smooth it with a spatula to a certain thickness; the thickness is 10mm.

Embodiment 3

[0031] An embossed textured decorative mortar, which consists of the following components by weight and is evenly mixed in a dry mixer: 18 parts of ordinary Portland cement, 2 parts of heavy calcium powder, 10 parts of 10-40 mesh quartz sand, 40 20 parts of ~80 mesh quartz sand, 46 parts of 80~120 parts of quartz sand, 2 parts of acrylic latex powder, 0.3 part of methyl cellulose ether, 0.3 part of polypropylene fiber, 0.5 part of wood fiber, 0.6 part of expansion agent, 0.3 part of water repellent share.

[0032] Wherein the expansion agent is a calcium oxide expansion agent;

[0033] The preparation method is the same as in Example 1.

[0034] Construction method: (1) Add water to the textured decorative mortar and mix until it is evenly mixed; the amount of water added is 21% of the weight of the mortar. (2) Apply the mixed embossed texture decorative mortar to the wall in batches, and smooth it with a spatula to a certain thickness; the thickness is 6mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com