Pretreatment technology of hot-galvanizing wastewater

A hot-dip galvanizing and pretreatment technology, applied in the removal of phosphate ions and solid particles, the pretreatment process of hot-dip galvanizing wastewater, and the field of zinc in wastewater, can solve problems that affect the production and life of residents and destroy ecological balance, and achieve Less equipment, lower organic load, and lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

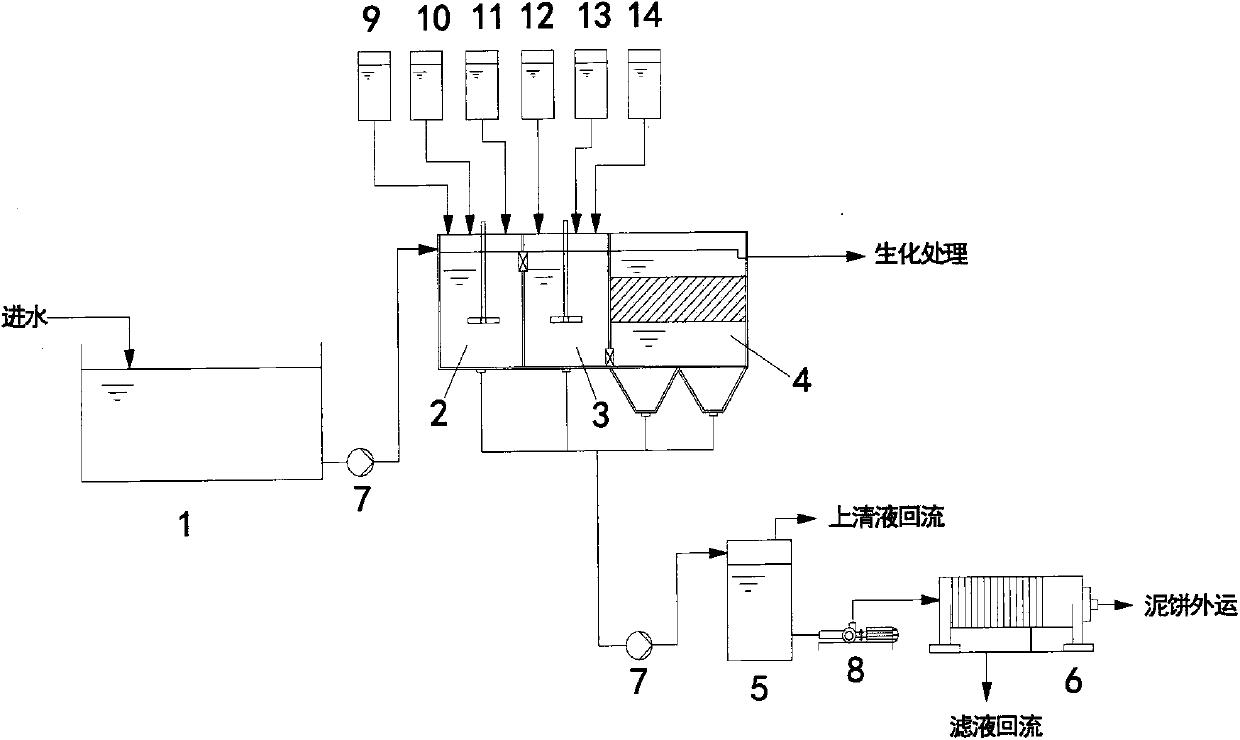

Image

Examples

Embodiment 1

[0021] A hot-dip galvanized steel sheet production enterprise produces 150,000 tons of hot-dip galvanized steel sheets annually, and produces 315 tons of hot-dip galvanized wastewater per day. The wastewater quality indicators are shown in Table 1 below.

[0022] Unit: mg / L

[0023] water quality index

[0024] Table 1

[0025] After the hot-dip galvanizing wastewater is treated by the process of the present invention, the effluent water quality index is shown in Table 2 below after testing.

[0026] Unit: mg / L

[0027] water quality index

[0028] Table 2

Embodiment 2

[0030] A hot-dip galvanized steel sheet production enterprise produces 100,000 tons of hot-dip galvanized steel sheets annually, and produces 230 tons of hot-dip galvanized wastewater per day. The pollution factor indicators in the wastewater are shown in Table 3.

[0031] Unit: mg / L

[0032] water quality index

[0033] table 3

[0034] After using the process of the present invention to treat the hot-dip galvanizing wastewater, after analysis, the water quality index of the effluent is shown in Table 4.

[0035] Unit: mg / L

[0036] water quality index

[0037] Table 4

Embodiment 3

[0039] A hot-dip galvanized steel sheet production enterprise produces an average of 350 tons of hot-dip galvanizing wastewater per day, and the indicators of wastewater pollutants are shown in Table 5.

[0040] Unit: mg / L

[0041] water quality index

[0042] table 5

[0043] After the hot-dip galvanizing wastewater is treated by the process of the present invention, the water quality indicators of the effluent are shown in Table 6 after analysis.

[0044] Unit: mg / L

[0045] water quality index

[0046] Table 6

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com