Anti-rollover device for use during loading and unloading of coal mine car

A technology for loading and unloading and anti-rollover, which is applied in the loading and unloading, transportation and packaging of railway vehicles, railway car body parts, etc. Guarantee work safety and good implementation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

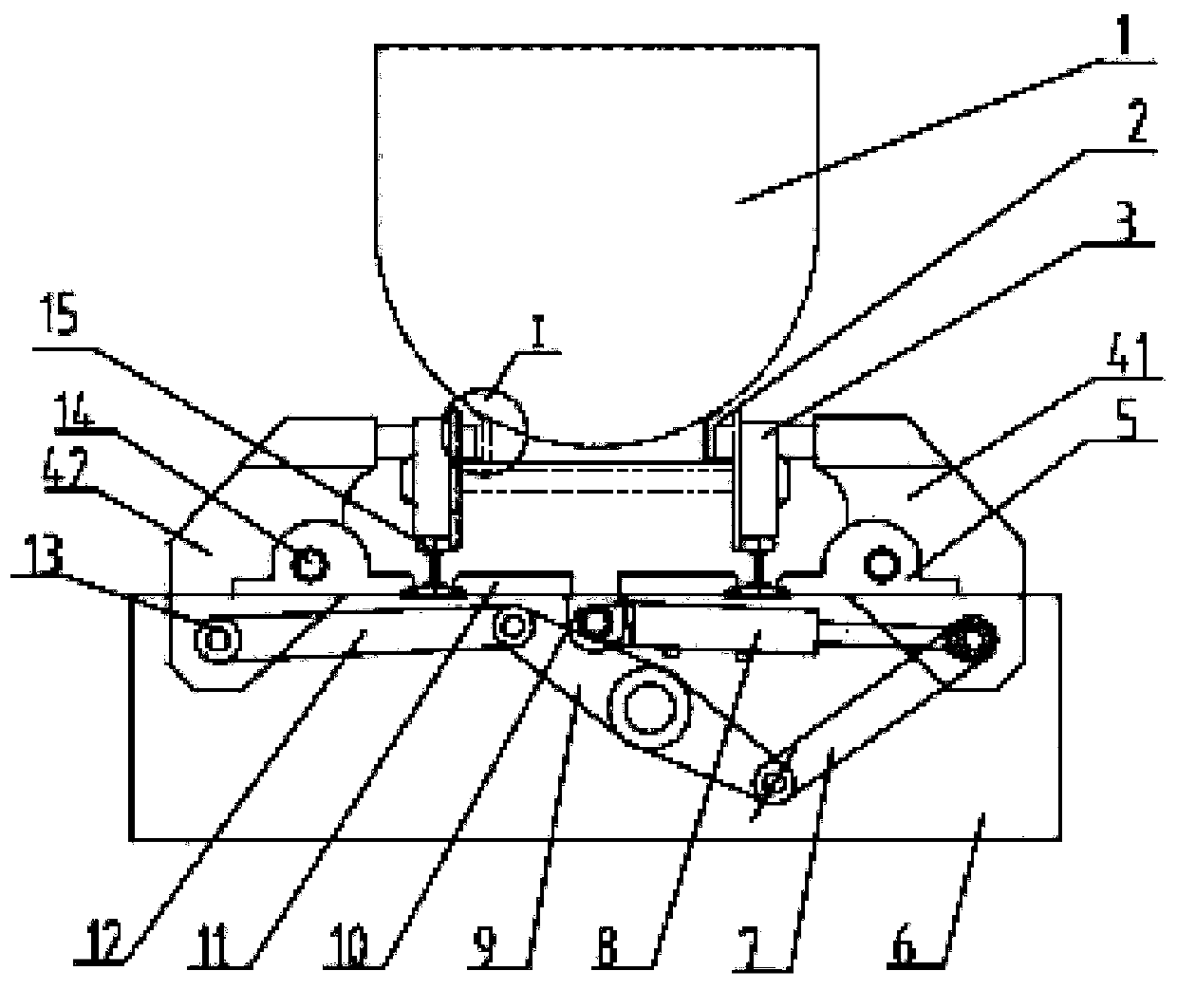

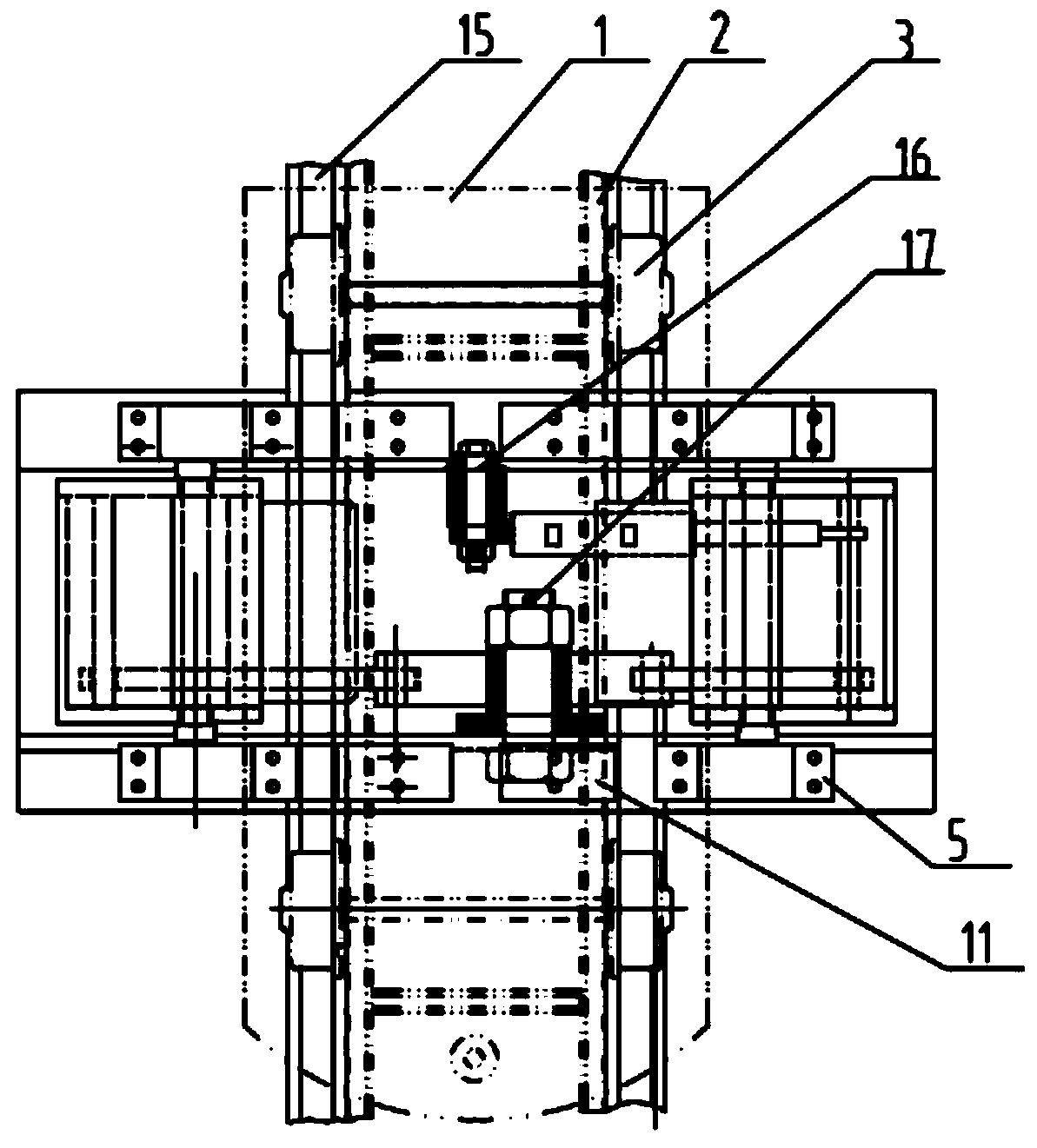

[0017] The technical solution of the present invention will be further explained and illustrated through specific embodiments below in conjunction with the accompanying drawings.

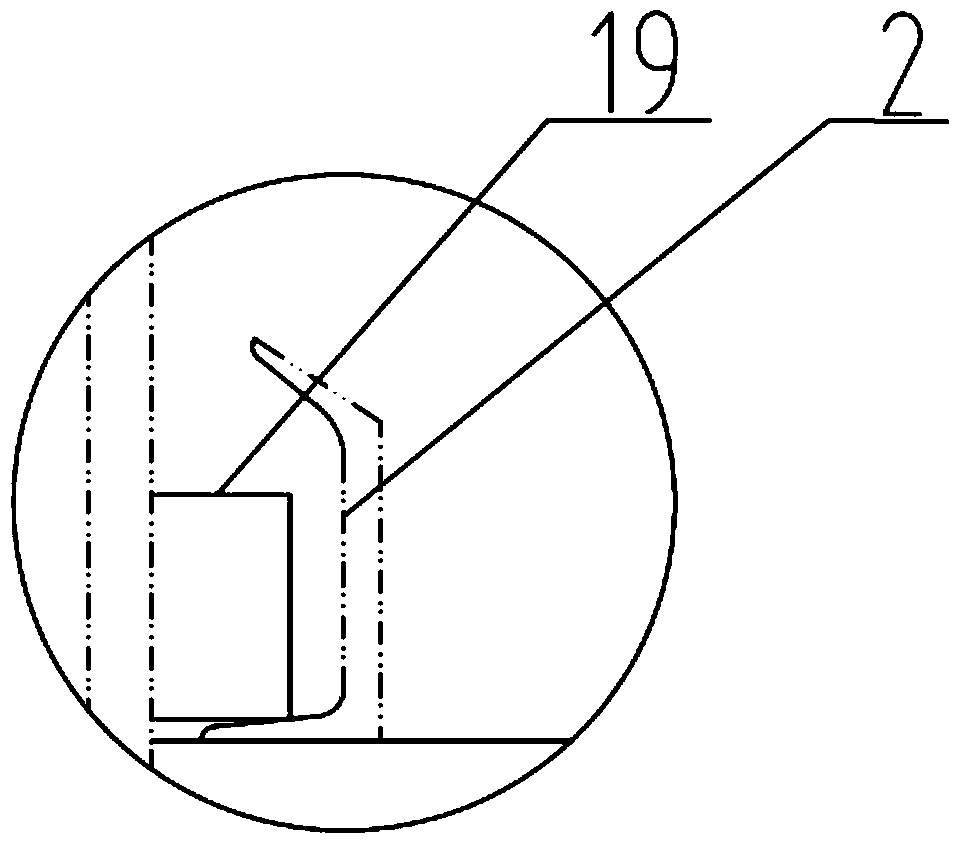

[0018] The rollover device as shown in the figure includes a fixed frame 6, which is detachably installed below the mine car track 15, and the fixed frame 6 is provided with a clamp, and the clamp includes a corresponding 15 both sides form the left turning arm 42 and the right turning arm 41 that are rotationally connected with the fixed frame, the left turning arm 42 and the right turning arm 41 one ends are all provided with chuck 19, and chuck 19 is arranged on two sides of mine car 1 chassis. The lower part of the groove of the oblique leg channel steel 2 with the horizontal opening on the side is press fit, and the oblique leg side is close to the mine car box body, which improves the strength of the mine car box body and makes way for the chuck to rotate; The other end of arm 41 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com