Electric vehicle powertrain

A powertrain and electric vehicle technology, applied in the direction of electric power units, power units, vehicle components, etc., can solve the problems of reduced driving range, high noise, low manufacturing cost, etc., and achieve fast shifting response speed and load capacity Strong, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

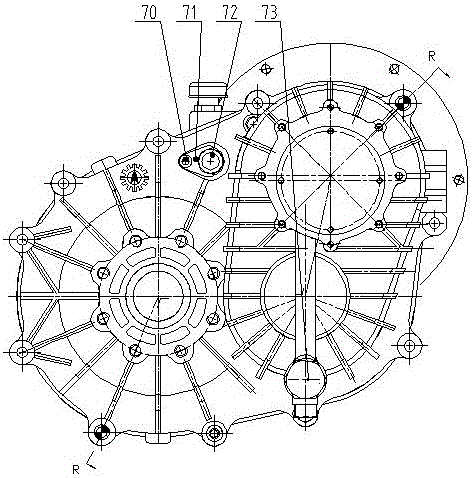

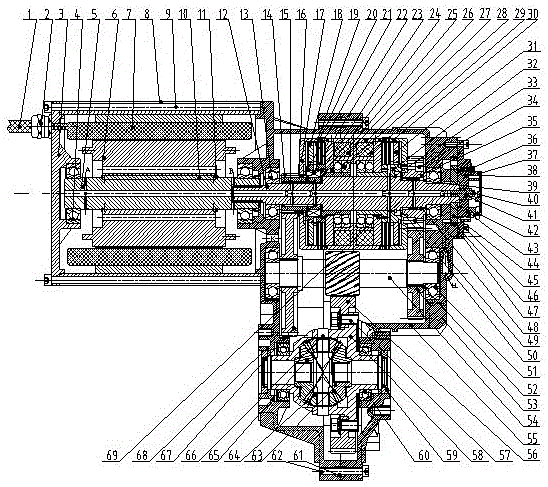

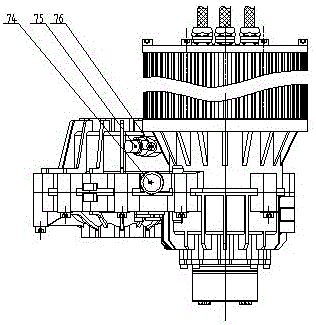

[0016] The technical scheme of the present invention will be described in detail below in conjunction with the drawings: the electric vehicle power assembly used in the electric vehicle is mainly composed of a motor unit and a transmission unit; the motor unit is composed of a motor shaft 5, a motor rotor 6, and a motor stator 7. , Motor housing 8, motor end cover 3, motor bearing 4, motor stator lead 1, motor insulation bolt 2; motor shaft 5 and motor rotor 6 are coaxial and fixed with flat keys 10, and motor shaft clamp 11 is used to fix the motor For the axial position of the rotor 6, the motor bearing 4 is connected with the motor shaft 5 by interference fit, and one end is matched with the bearing hole provided in the motor end cover 3, and the other end is connected with the bearing hole provided in the upper housing 68 of the transmission; the motor stator 7 It is connected with the motor housing 8 by interference fit, and the lead wire 1 of the motor stator 7 extends thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com