Automatic drawing, gluing and glitter scattering machine for artware

A technology of handicrafts and automatons, which is applied in the fields of crafts, decorative arts, and special decorative structures for producing decorative surface effects, and can solve problems such as aesthetics inspection, uneven glue coating, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Left, right, up and down in the present invention are only for describing relative positions.

[0017] In the present invention, the left and right driving devices can drive the connected parts to move linearly left and right, the up and down driving devices can drive the connected parts to move linearly up and down, and the rotary driving device can drive the connected parts to rotate. The left and right driving devices and the up and down driving devices can be selected from cylinders, Oil cylinders, or linear motors, for cost and control reasons, the best use of air cylinders, rotary drives can use a combination of motors and drive trains.

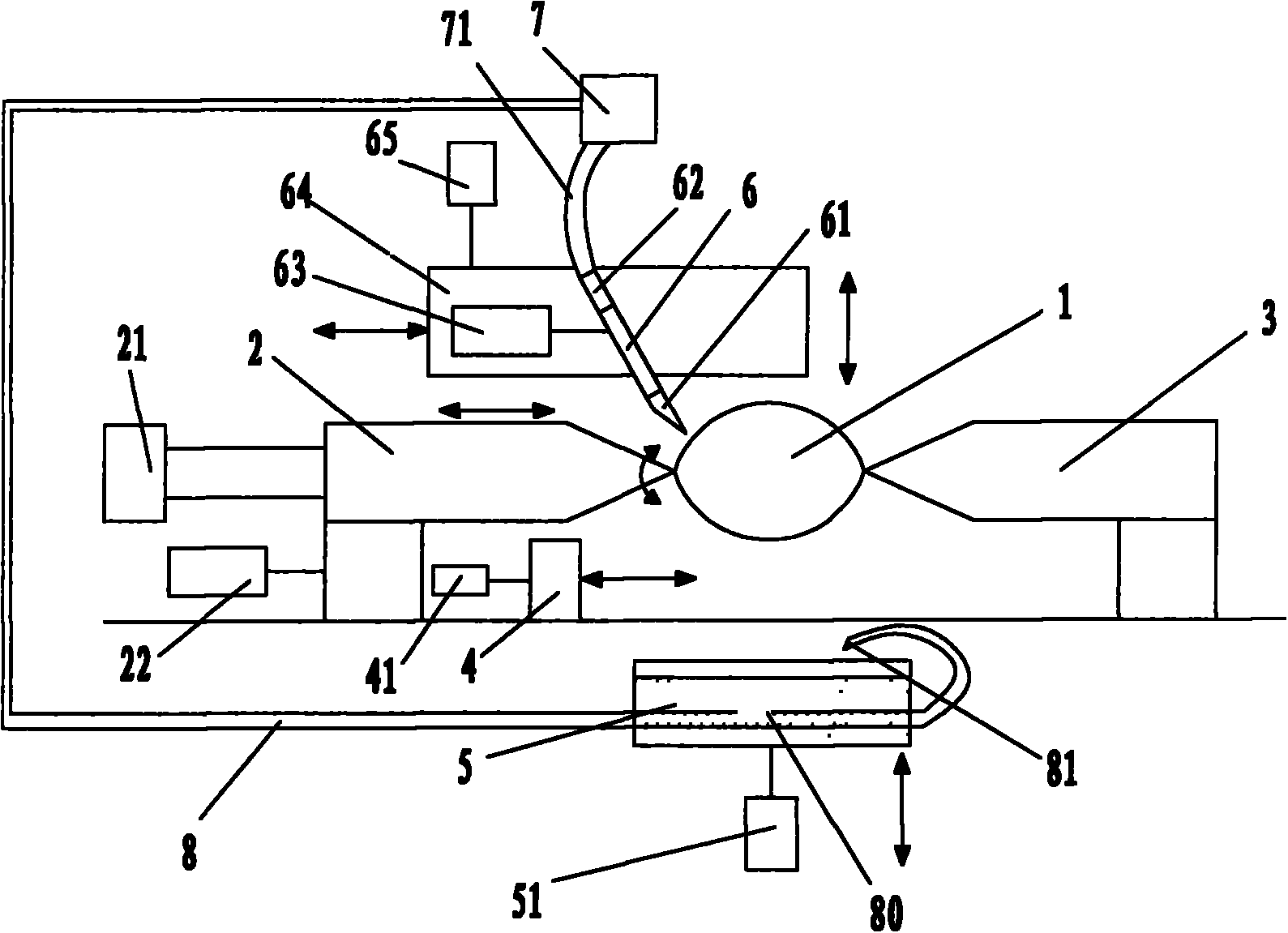

[0018] Such as figure 1 Shown:

[0019] The present invention has a frame (not shown in the figure), and the frame is used as the basis of the installation structure.

[0020] The frame is provided with two oppositely arranged left fixed arms 2 and right fixed arms 3, the ends of the left fixed arms 2 and the right fixed arms 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com