Tool for pressing signal wheel on camshaft

A camshaft and signal wheel technology, used in manufacturing tools, workpiece clamping devices, hand-held tools, etc., can solve problems such as low product qualification rate and signal wheel angle deviation, achieve reliable operation, prevent angle deviation, and improve product quality. The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

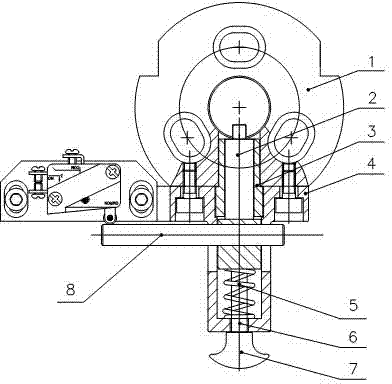

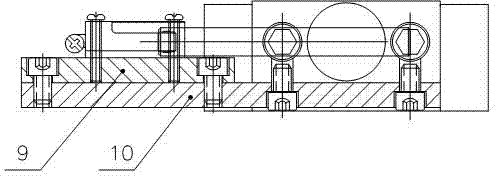

[0015] like figure 1 and 2 As shown, the camshaft press-mounted signal wheel tooling of the present invention includes a positioning seat 1, a positioning hole is provided in the middle of the positioning seat 1, a bottom plate 10 is provided at the front lower end of the positioning seat 1, and an end cover 4 is provided at the front upper end. The base plate 10, the end cover 4 are fixedly connected with the positioning seat 1; the left side of the base plate 10 is provided with a mounting plate 9, which is fixedly connected on the base plate 10; the positioning seat is provided with a positioning shaft mounting hole, and the positioning shaft The center line of the mounting hole intersects vertically with the center line of the positioning hole; the end cover 4 is provided with a hollow inner cavity, which communicates with the mounting hole of the positioning shaft; a positioning sleeve 3 is arranged in the mounting hole of the positioning shaft, and the positioning sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com