Method and device for producing metal 3D printing method product

A technology of 3D printing and production method, which is applied in the field of high-temperature sintering, alloying and densification to produce metal parts and components, and can solve the problems of high power, high cost, and large-scale commercial investment of laser generators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

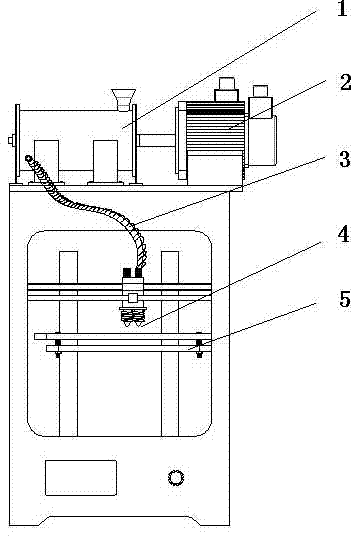

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention is described as follows by using 3D printing stainless steel 316L material metal parts and components as an example:

[0016] one. Preparation of Metal Powder Mixtures for Thermoplastic Forming

[0017] (1) Select stainless steel 316L grade spherical metal powder with an average particle size D50=25μm

[0018] (2) Thermoplastic molding binder composition: 50% paraffin + 50% polyethylene

[0019] (3) Mixing: 60% metal powder content + 40% molding binder volume content, using a 5 kg screw mixer, mixing 20 kg of the mixture at a temperature below 120 ° C for 20 hours.

[0020] two. 3D printing formed metal parts green body

[0021] (1) Use professional 3D printing software to design the three-dimensional metal parts product model to be printed in the computer, set the printing parameters, and control the temperature of the print head of the 3D printer by the low-temperature fusion deposition molding method (FDM method) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com